Optimizing energy and process efficiency using forward-thinking control solutions is one of the key criteria for the sustainable development of urban environments. Efficient solutions based on intelligent networking are required in all relevant areas - from sustainable energy generation in decentralized biogas plants and intelligent energy-saving systems to control of district heating systems and smart cities.

In the case of biogas systems, the control requirements appear to be less complex at first glance. However, in order to ensure the economic efficiency of a plant and maximize energy yield, the microbiological process requires optimum conditions such as temperature, pH value and pressure to be continuously monitored by the control system. Faults or events that exceed the maximum values must be identified automatically and reported to the operator. What is also important for most decentralized plants is the possibility to implement remote monitoring and control. The requirements are even more complex when it comes to automating intelligent storage systems, which are used to compensate for frequency fluctuations when supplying sustainable energy sources. These systems store energy in case of excess capacity, so that they can feed back into the grid if production bottlenecks arise. This requires optimum energy storage management based on continuous recording and monitoring of energy data and fast communication using telecontrol protocols. Forward-thinking solutions for efficient energy generation therefore require the highest degree of connectivity.

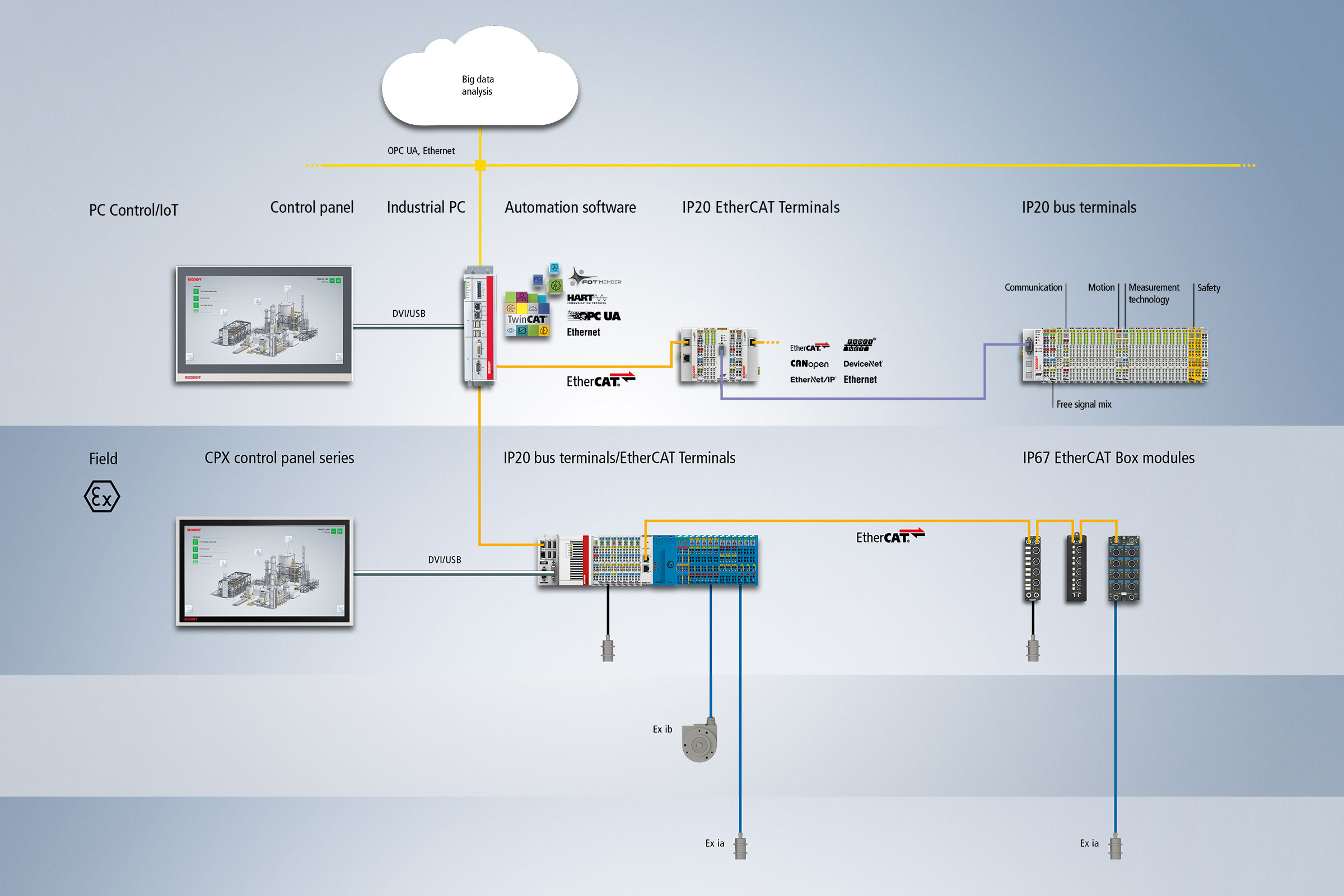

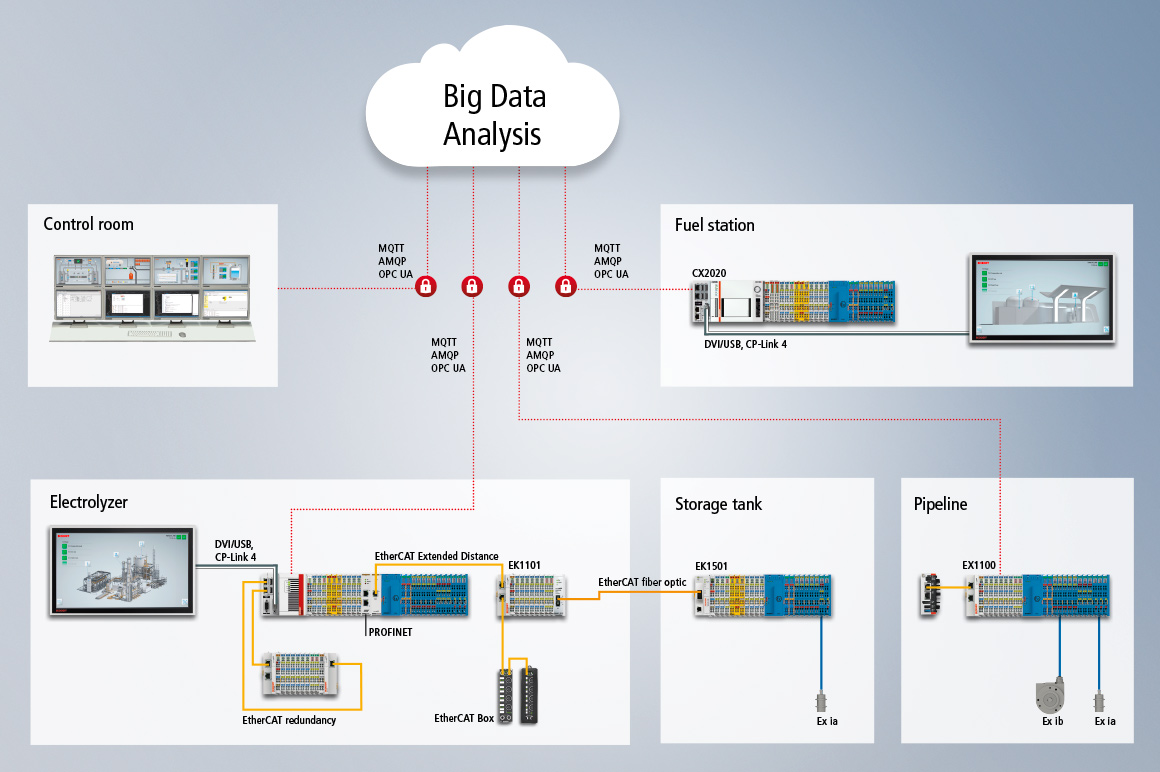

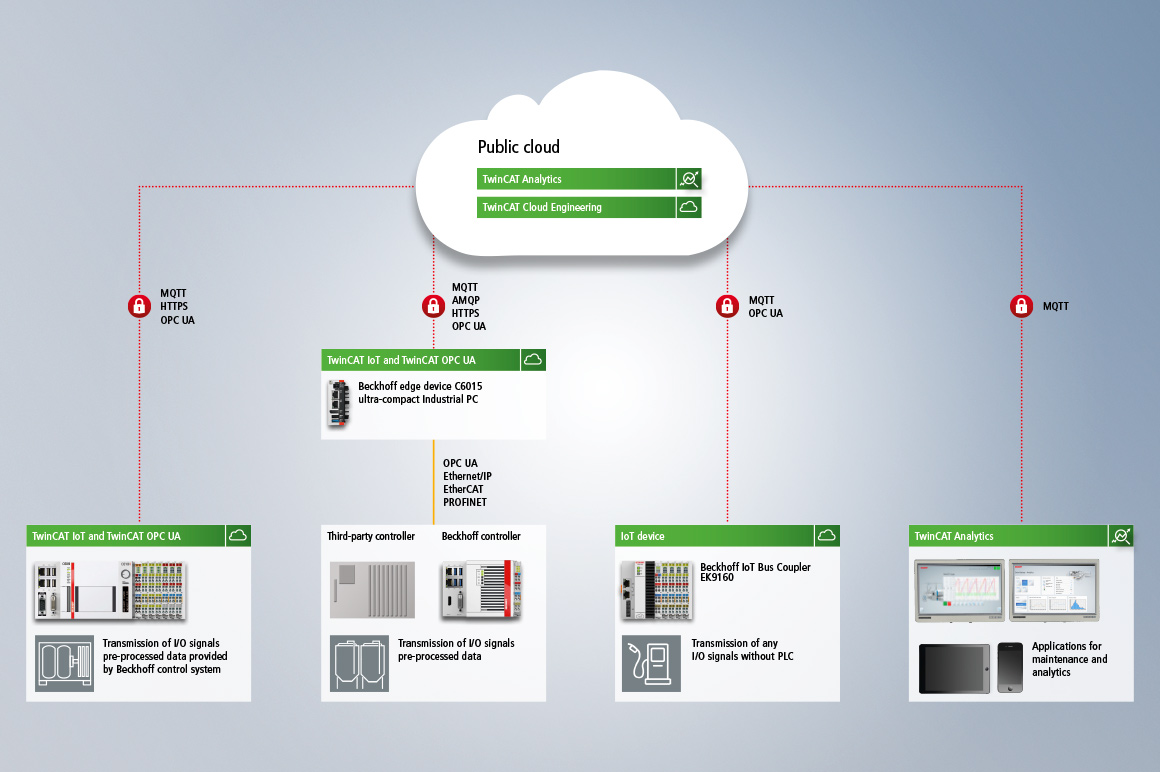

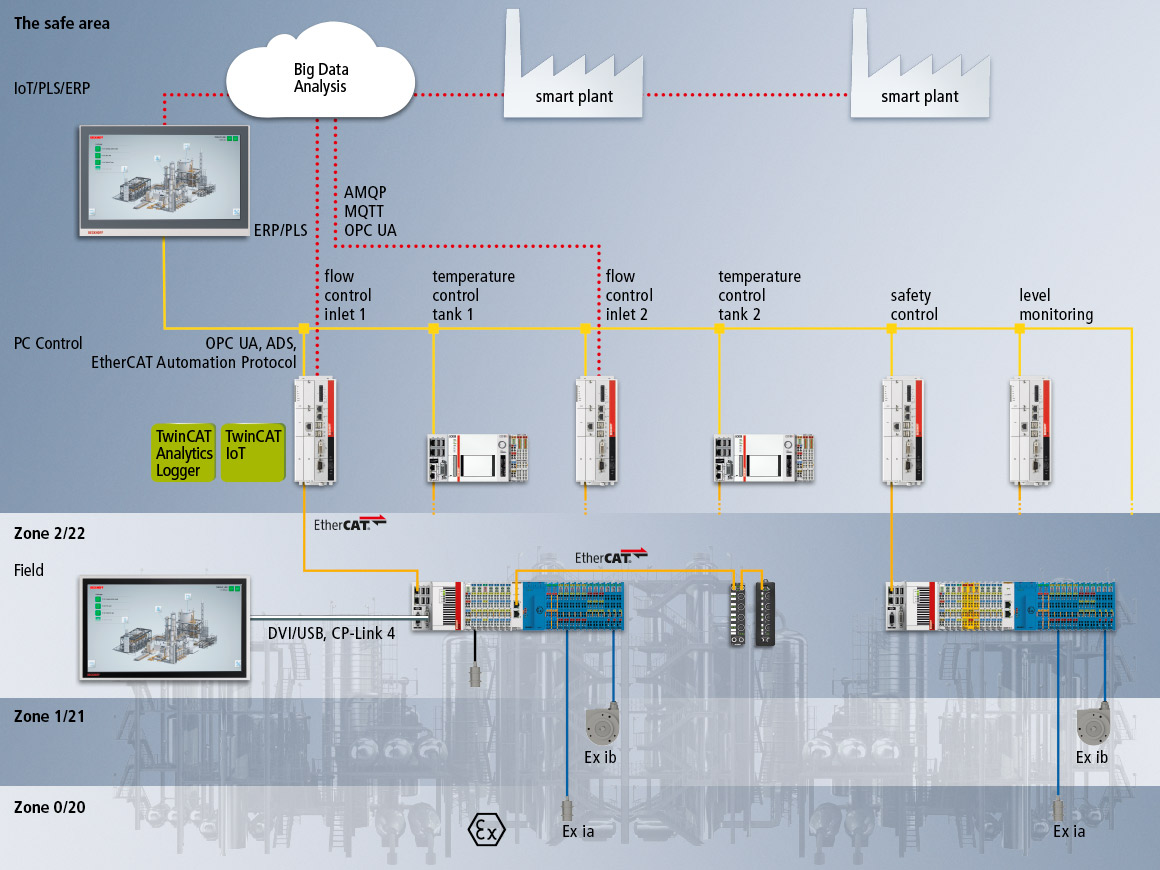

To meet these challenges, Beckhoff control technology supports all common communication standards in the area of fieldbus systems and the software-based integration of all common communication protocols. Reliability, fast data transmission, flexibility and powerful scalability to implement cost-effective solutions are important requirements in the energy sector. These requirements can be ideally met with PC-based automation. A comprehensive portfolio of measurement technology modules enables reliable recording of temperature, pressure and flow rates, for example. Condition monitoring and power monitoring can also be integrated into the automation platform via corresponding interfaces to provide a basis for predictive maintenance and the evaluation of raw current and voltage data.

Application reports and brochures

- 02.09.2024 | Application report

Consistent use of renewable energies with flexible metal hydride storage systems

GKN Hydrogen, ItalyThe proportion of renewable energies from solar, wind and water is rising continuously. However, sufficient storage options are of the essence to use these energies as efficiently as possible – in the event of surplus supplies, for example. GKN Hydrogen offers a particularly compact and safe option: low-pressure metal hydride hydrogen storage systems which are controlled by PC-based control from Beckhoff.

- 16.07.2024 | Application report

Transmitting high power efficiently over long distances

MathWorks und Siemens Energy, GermanyWhether from offshore wind turbines on the high seas to the mainland, from wind turbines in northern Germany to industrial sites in the south of the country, or from hydropower plants in Scandinavia to central Europe – high-voltage direct current transmission is used to transmit large amounts of energy over long distances. For its solution, Siemens Energy relies on MATLAB and Simulink from MathWorks and PC-based control from Beckhoff.

- 06.06.2024 | Brochure

The control system for process automation: PC-based control

Beckhoff offers open automation solutions for the process industry: PC-based control provides a universal control system that can be used to automate all plants and processes.

- 08.04.2024 | Application report

Highly compact implementation and automation of sophisticated process technology

Reverion, GermanyJust flip the switch – that could quite easily be the motto of Reverion’s biogas power plants on the way to a climate-friendly energy supply. As if the compact design housed in a single transportable container didn’t make using this energy technology easy enough already, its exceptionally high efficiency of 80%, reversible usage option, and seamless data monitoring with PC-based control from Beckhoff all serve as prerequisites for achieving a high level of automation.

- 17.07.2023 | Application report

85% efficiency in trigeneration plant with fast process control

AIEglobal, AustraliaIn thermal power plants, more than 50% of the energy is usually lost in the form of heat. The natural gas driven power plant at Melbourne Airport, on the other hand, uses the waste heat to generate heat and cooling, thus achieving a much higher energy yield. This is helped by Beckhoff Embedded PCs and EtherCAT I/Os enabling fast control and regulation of the plant, which automatically switches to emergency power supply in the event of a power failure.