Headquarters India

Beckhoff Automation Pvt. Ltd.

+91-20-6706 4800

info@beckhoff.co.in

www.beckhoff.com/hi-in/

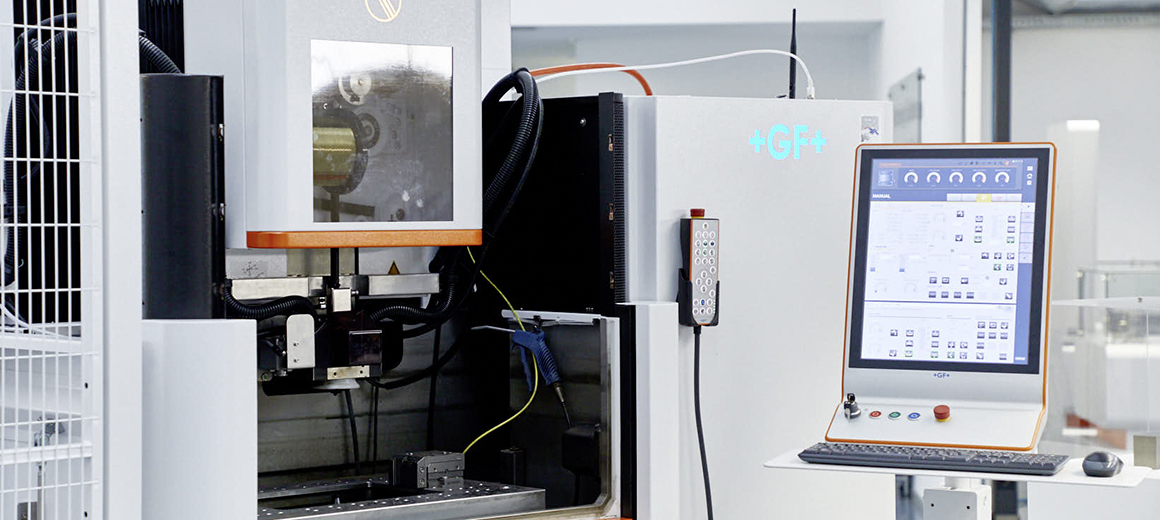

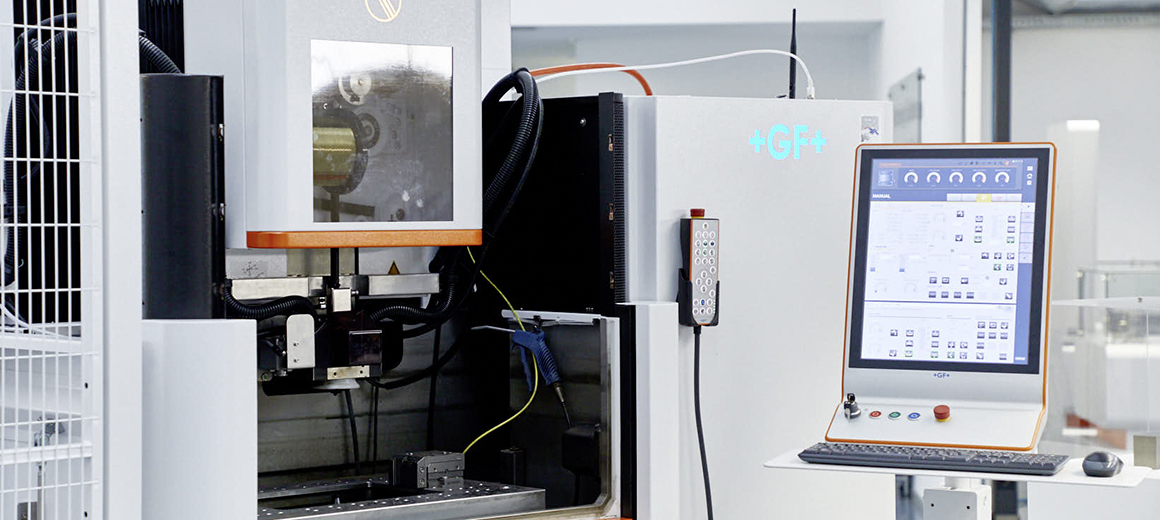

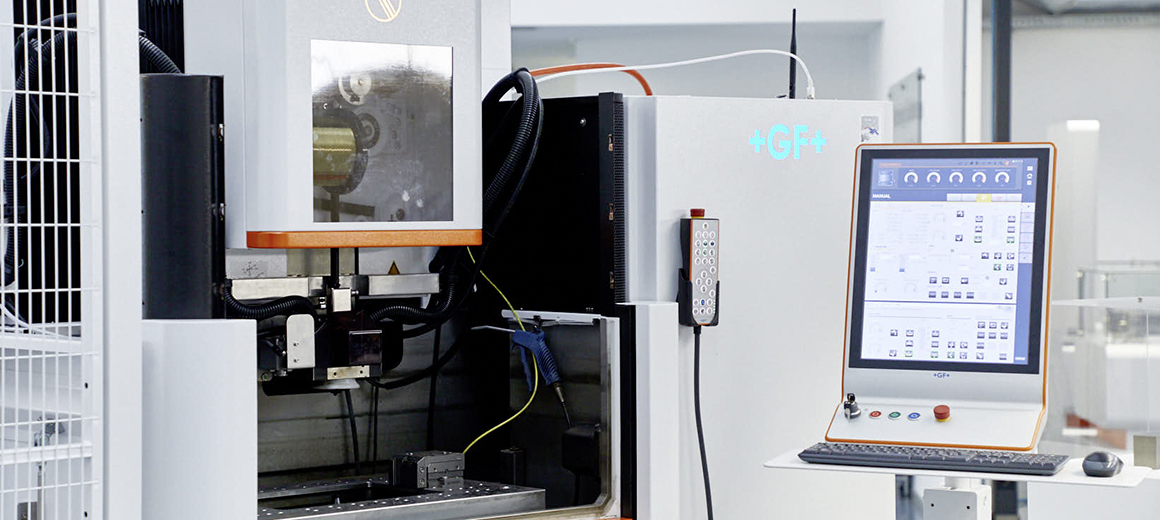

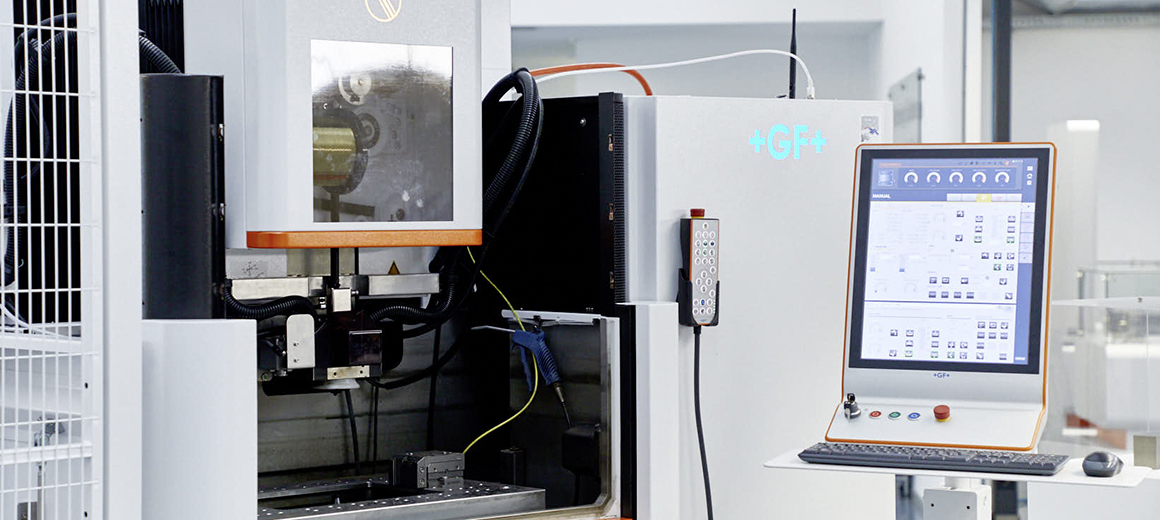

End users and manufacturers of machines for sheet metal working and metal forming are faced with high demands: High productivity must be guaranteed as well as a maximum degree of individualization and high quality standards. In order to be able to produce competitively, the machines must also be optimized with regard to their footprint and energy consumption. In order to meet these requirements, modern automation technology is required, as we offer with PC-based control.

Modular in structure and precisely scalable to meet the requirements of the specific application, PC-based control is suitable for the entire range of requirements – from the single machine to the industrial linked plant. Since all functions are consistently transformed into software, only one CPU is required for PLC, visualization, motion control, safety and measurement technology. In combination with the direct cloud connection Industrie 4.0 concepts can be realized and every process stage can be optimized. Improved production processes, increased workpiece quality and increased output bring clear competitive advantages. The reduced control complexity ensures greater reliability and simpler maintenance of machines and plants.

Beyond the high-performance control technology, EtherCAT and EtherCAT P in particular provide for a competitive advantage in press lines. We offer a wide range of CNC functions for cutting and welding plants. Special applications for punching and nibbling are supported by fast signal processing based on EtherCAT and EtherCAT XFC. With the software library TwinCAT 3 Hydraulic Positioning, ready-made function blocks are available for bending processes in folding, roller bending or pipe bending machines. In addition, you can rely on our expertise acquired over many years of cooperation with our customers in the field of sheet metal working and forming. We offer comprehensive application support for both new plants and machine retrofits.

The Beckhoff CNC solution enables highly dynamic axis movements in punching and nibbling.

PC-based control from Beckhoff provides the ideal platform to automate folding and bending processes.

Cincinnati Incorporated (CI) has been building sheet metal processing equipment for 125 years and continues to support its durable machines for decades. The company is able to do this because it develops everything in-house, from the hardware to the software. However, the further development of proprietary control technology became too costly and challenging to support. Since the switch to PC-based control, the only limits to development have been physical, according to the engineers at CI.

In die casting, vacuum generation in the shot chamber and mold cavity helps to avoid air and gas inclusions in the castings, as these would impair the stability of the finished parts. For this purpose, AJYa Vacuum Technology from China developed a complex but particularly effective multi-stage solution. A suitable control platform was implemented in cooperation with the automation partner Beckhoff.

As a specialist in PC-based control technology, Beckhoff provides proven, high-performance automation solutions for sheet metal working.

Haeusler AG, based in Duggingen, Switzerland, is a leading specialist in large-scale facilities for forming metal plates. At the end of 2020, a giant 1,245-ton straightening machine was delivered to one of the largest shipyards in China. The company explains that this plant, the largest of its kind in the world, is used in the production of oil tanker hulls. In this context, PC-based control technology from Beckhoff ensures that the enormous forces for precisely forming steel parts are guided in the right direction.

When it comes to producing high-quality railroad tracks, two Chinese specialists rely on the performance of PC-based control technology from Beckhoff: Chengdu Aigre Technology Co., Ltd. (Aigre Tech) applies it with a rail-straightening machine to create seamless tracks, as does China Railway Chengdu Group Co., Ltd. with a tandem crane lifting system made up of four overhead cranes.