Products

AX1000 | Economy servo drives

The AX1000 economy servo drive for implementing demanding and cost-sensitive drive tasks.

AX8000 | Multi-axis servo system

The AX8000 is the space-saving solution for applications with more than two axes. Extensive TwinSAFE functions allow a safe machine design.

AX5000 | Digital compact servo drives

The AX5000 is offered in a wide performance range and offers a flexible motor and feedback interface as well as optional TwinSAFE functions.

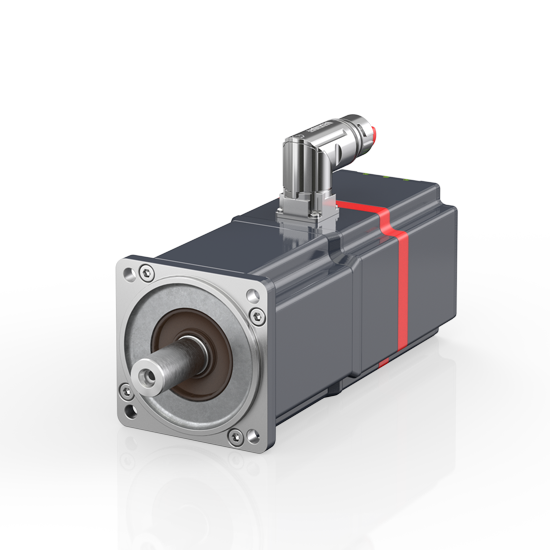

AMP8000 | Distributed servo drives

Synchronous servomotor with integrated servo drive for the realization of modular machine concepts without a control cabinet.

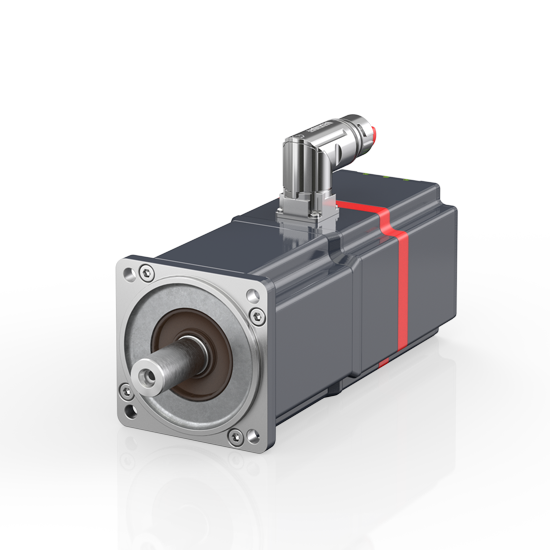

AMP8500 | Distributed servo drives with increased rotor moment of inertia

AMP8500 for the realization of modular control cabinet free machine concepts with high requirements on synchronism and control quality.

AMI8100 | Compact integrated servo drives

Synchronous servomotor with integrated servo drive for the realization of machine concepts without a control cabinet in the low voltage range.

ASI8100 | Compact integrated stepper motor drives

Stepper motors with an integrated stepper motor output stage for low-voltage control cabinet-free machinery concepts.

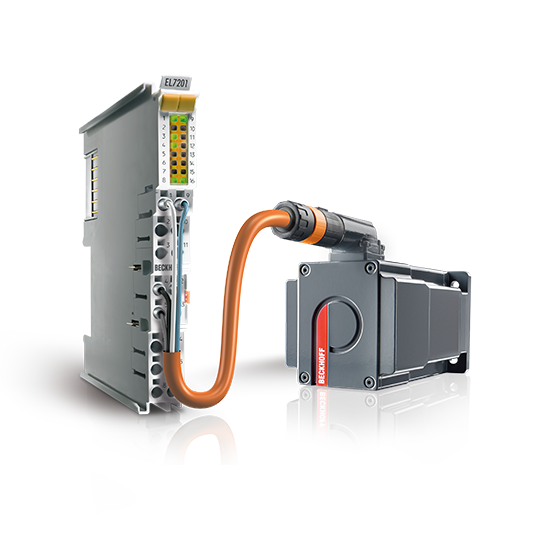

I/O components

The I/O components in different protection classes enable the operation of stepper, DC and servomotors in a compact design.

Software

The motion software products optimally support the selection and commissioning of suitable hardware components for drive solutions.

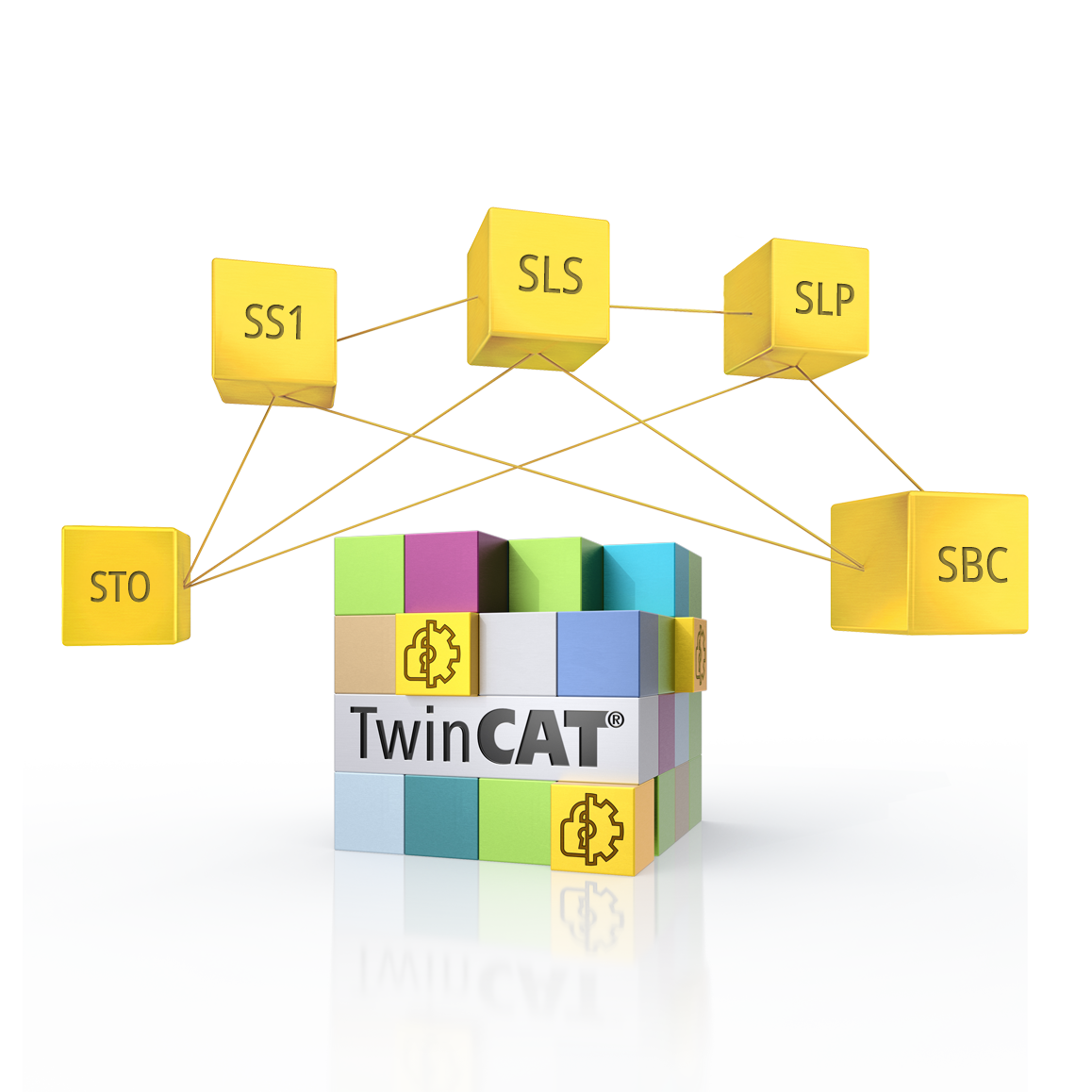

TwinSAFE safe drive technology

With the TwinSAFE safe automation technology, both basic functions and complex safety functions are available for all our drive solutions.

Innovation and efficiency – tailor-made servo drives for every application

Modular and compact

The AX1000 economy servo drives are a particularly cost-efficient series that meets the highest technological standards. The AX1000 is available in two different versions: with a single-phase supply of 1 x 110 V AC to 240 V AC in the low power range from 1.65 to 6.9 A and a three-phase supply of 3 x 208 V AC to 480 V AC in the higher power range from 3.4 to 6.9 A. Both versions are available as single-axis and dual-axis versions. The devices support AM8000 series synchronous servomotors with One Cable Technology (OCT), as well as asynchronous and reluctance motors.

The AX8000 is one of the most compact multi-axis servo systems that can be used worldwide on almost all mains systems. The modules are mounted without tools thanks to the new AX-Bridge with integrated spring balancer technology. State-of-the-art multi-core processor technology enables highly dynamic control cycles. With TwinSAFE, up to 17 drive-integrated safety functions are available to make machines safer. In the integrated TwinSAFE Logic, safety functions can be programmed directly in the axis module, enabling even shorter response times. Thanks to the optional multi-feedback interface, third-party motors can also be operated with EnDat 2.2, BiSS-C, TTL, or SinCos 1 Vss feedback.

The compact servo drives in the AX5000 series have extensive functionality and a flexible motor and feedback interface, and are available up to an output of 118 kW. The AX5000 impresses with its maximum economic efficiency, its extensive range of features, and its particularly attractive two-channel modules. There is also the option of versatile safety features that support safety-related applications with TwinSAFE control. The variable motor interface allows the operation of synchronous servomotors, asynchronous motors, linear motors, and voice coil motors. The optional AX-Bridge quick connection system significantly reduces the wiring work and rules out connection errors thanks to its easy handling.

Distributed and versatile

The AMP8000 consists of a combination of the proven AM8000 servomotors and a highly efficient servo drive. Innovative power electronics with coldswitch technology limit power losses to an unprecedentedly low level, and space required for the electronics is reduced to an absolute minimum. The integrated secure single-turn or multi-turn encoders enable the AMP8000 to be used in applications where functional safety is required. In addition, a mechanical limit switch can be dispensed with in most cases. The AMP8000 is connected with an EtherCAT P cable; no additional connections are required for operation.

In the compact drive technology product sector, the AMI8100 combines a servomotor with a servo drive and an EtherCAT interface in a space-saving design for all motion requirements in the power range up to 400 watts. As an EtherCAT slave, the AMI8100 can be placed directly on the machine without a control cabinet and without an upstream I/O level, which makes it possible to create compact and modular control cabinet-free machines. The current state is indicated by the integrated status LEDs. The distributed servo drives are optionally available with TwinSAFE STO/SS1 safety functions.

Supplementary and intuitive

An extensive and optimally matched range of accessories completes the servo drive portfolio. The drive system is usefully completed with pre-assembled cables, mains filters, wiring aids, and various components for energy management.

The motion software products optimally support the selection and commissioning of suitable hardware components for drive solutions.