More motion, more control

Scalable drive solutions for packaging machines

Siège social Suisse

Beckhoff Automation AG

Scalable drive solutions for packaging machines

Packaging machines are as diverse as the range of applications that they are built for. Manufacturers like you, however, are faced with the same requirements over and over again. Regardless of whether your customers need a packaging system for food, pharmaceutical, cleaning, or cosmetic products, they will be looking for a system that demonstrates impressive quality and performance, saves resources, can be used flexibly to accommodate small batch sizes, and is scalable.

To meet these requirements, you need leading drive and motion control solutions – ideally from a system supplier that can give you perfectly harmonized options for both. That’s where Beckhoff Automation comes in. Our strength lies in combining a deep understanding of the industry with innovative strength – through TwinCAT MC3, for example, our latest generation of motion control for systems with an unlimited number of axes.

Beckhoff's benefits for you:

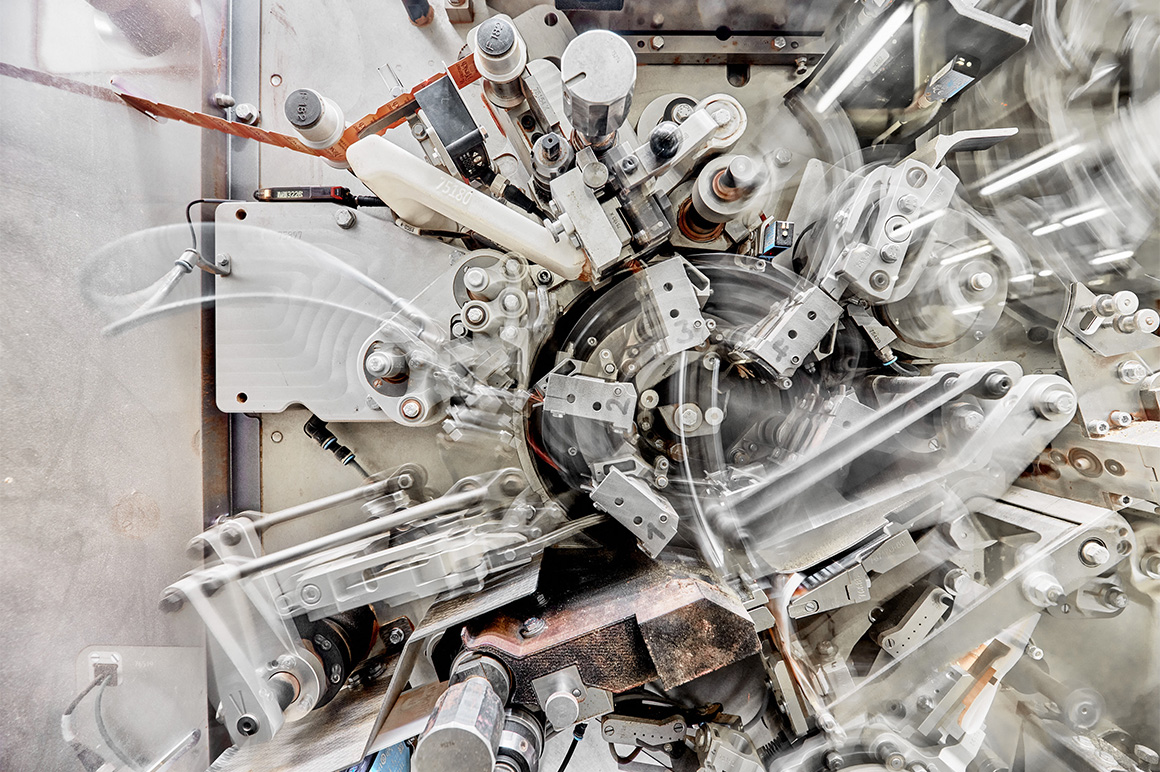

Demanding packaging processes involve countless steps – including gripping, filling, closing, placing, marking, and ejecting, all of which need to run quickly, precisely, and efficiently in a single machine.

These come with engineering challenges:

Beckhoff provides you with everything you need:

Small batch sizes and short product life cycles require flexible packaging machines.

The engineering challenges you face include:

Beckhoff provides the hardware and software you need to achieve this:

Reducing the amount of raw materials and energy used in packaging processes makes economic sense and helps ensure compliance with regulations.

For manufacturers and developers, this means:

These requirements can be met with drive solutions from Beckhoff:

TwinCAT MC3 sets new motion control standards. The new development boosts the speed, precision, and synchronization of all motion sequences involved in packaging processes. More scalability and openness provide added benefits – including when it comes to integrating different drive and robotic systems.

Highlights and advantages:

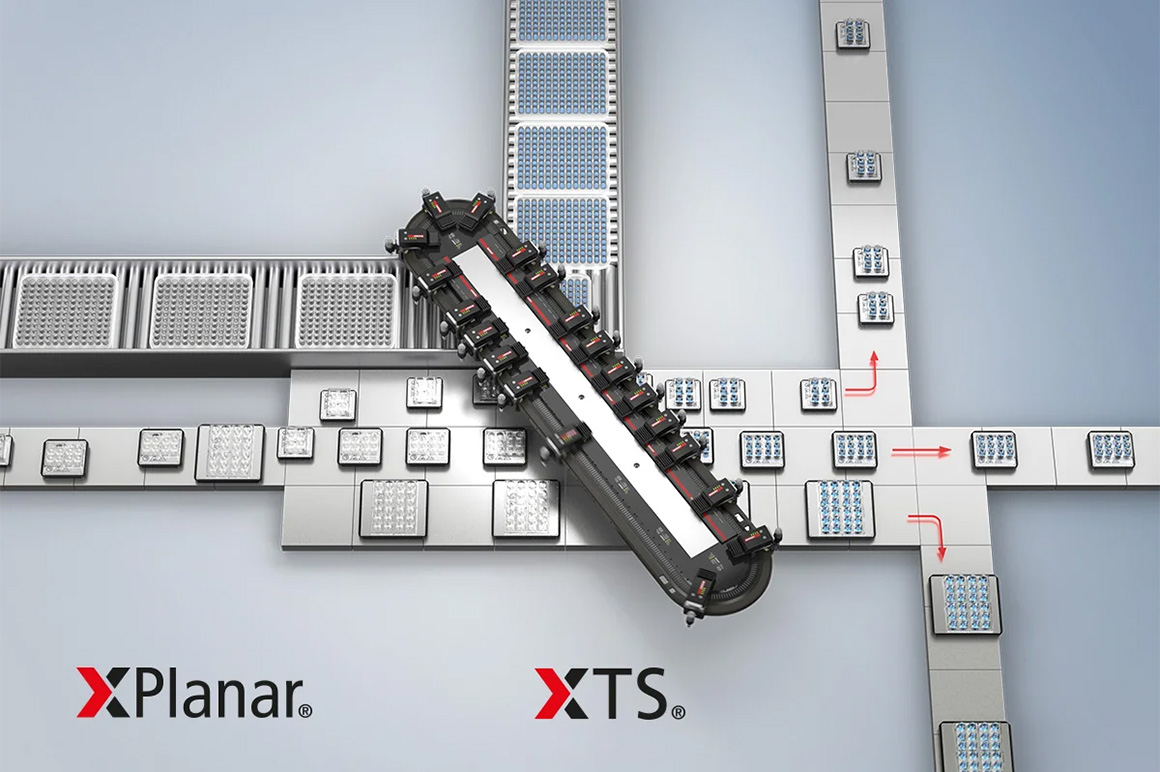

How do you make the transport routes in packaging machines more flexible and efficient? With intelligent systems such as the linear eXtended Transport System (XTS) or the XPlanar planar motor system. Both use the principle of passive movers and give you complete freedom when designing the system topology and transport routes. With XTS and XPlanar, this means that machines and systems can be fully rethought and redesigned.

With XTS, the eXtended Transport System, the magnetically driven movers travel along a path with fully integrated drive modules. This allows you to implement open or closed path layouts in countless geometries. Here's a tip: the XTS movers are also available with No Cable Technology (NCT) and can therefore be expanded into mobile handling and processing stations.

The XPlanar eXtended planar motor system gives the movers even more flexibility. The tile-shaped product carriers float in a magnetic field and move with up to six degrees of freedom in two dimensions over individually arranged XPlanar tiles – with precision, no wear, and no noise at speeds of up to 2 m/s.

Whether you’re looking for something highly dynamic, particularly space-saving, optimized for the highest hygiene standards, or individually tailored to suit every single one of your needs, Beckhoff can provide exactly the drive solution you need to stand out from the competition as a manufacturer of packaging machines and systems. Our system solutions are inherently freely scalable, open to technology, and designed for efficiency and sustainability – making them suitable for your needs now and in the future.

Our distributed drive technology is an example of this: Innovative servo drives such as the AMP8000 or AMI8100 feature integrated servo amplifiers with EtherCAT integration. The benefit of these drives is that they allow you to create control cabinet-free machine concepts that save space and meters of cable, and minimize maintenance costs.

What about drive solutions for specific application environments or special requirements? We also have the right expertise to develop these for you. A recent example is a drive with a water-cooled motor in a stainless-steel design – optimized for high speeds at high ambient temperatures. With the TwinCAT 3 Motion Designer, we provide a powerful and versatile tool for customizing the design of your drive solutions.

Our TwinCAT MC3 is the next generation of motor control. It is seamlessly integrated into TwinCAT and offers scalable performance with multi-core and multi-task support.

Our drive solutions for modern packaging machines took centre stage at Fachpack 2024. In this video, you can find out more about our hardware portfolio of decentralized drive technology, flexible transport systems such as XTS and XPlanar and the next-generation motion control solution – TwinCAT MC3.

Faulty products can be ejected without pausing the process with XTS Track Management. This video of the Koch PAC sealing machine shows you how this is achieved.