Thanks to the individual movement profiles of the XTS movers, it is not only conventional conveyor belts that can be replaced. In fact, the XTS enables the innovative design of entire systems. The heart of the mechatronic system is the software. This allows previously complex mechanical solutions to be replaced. The subsequent adaptation and reproduction of plants are also easy to implement. The XTS software supports the user from simulation to parameterization and from application programming to system diagnostics.

Integrated XTS simulation functions facilitate plant design

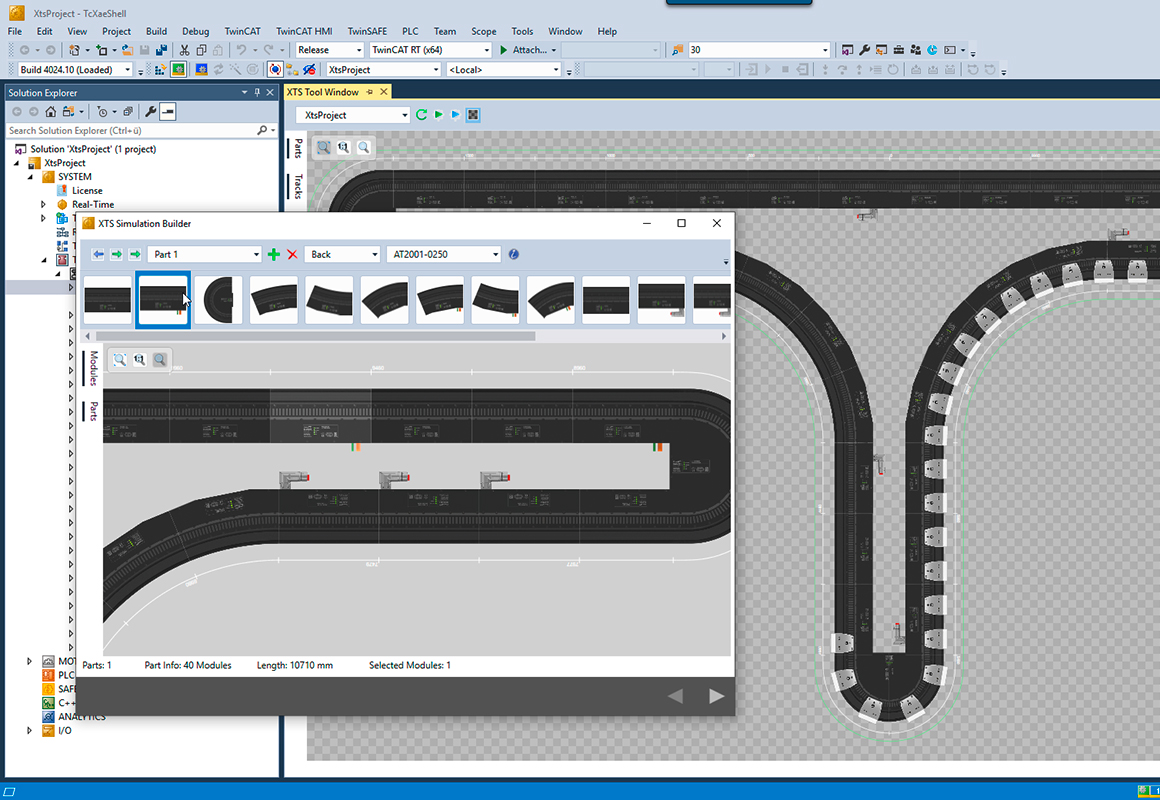

Even with careful planning and calculation of XTS applications, questions remain unanswered that can only be clarified by function tests. However, the XTS projection planning tools allow you to check many issues without a single piece of hardware: sequential control, power consumption, production rate and much more. Integrated XTS simulation functions also facilitate plant design. They enable the user to assemble any desired track layout from the XTS modular system, to check the subsequent integration into (existing) plant concepts and to verify application sequences. During the development process, all parameters (e.g. XTS track layout, number of XTS movers, etc.) can be adjusted as desired until the optimal solution is obtained. The generated program code can be reused for the physical hardware. The possibility of this parallelization of the work processes significantly speeds up the plant design and reduces the time-to-market.

XTS software tools support simple configuration

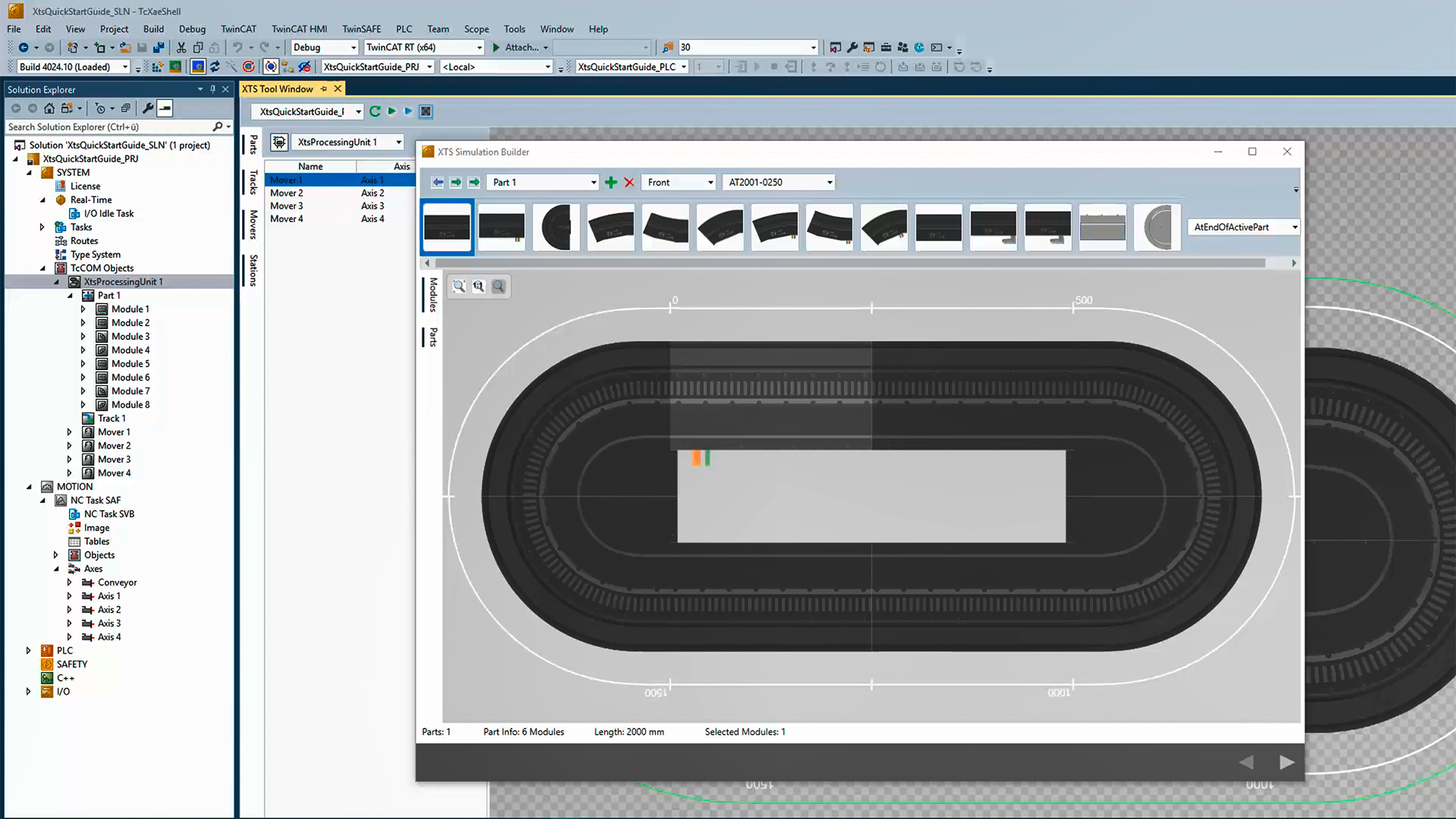

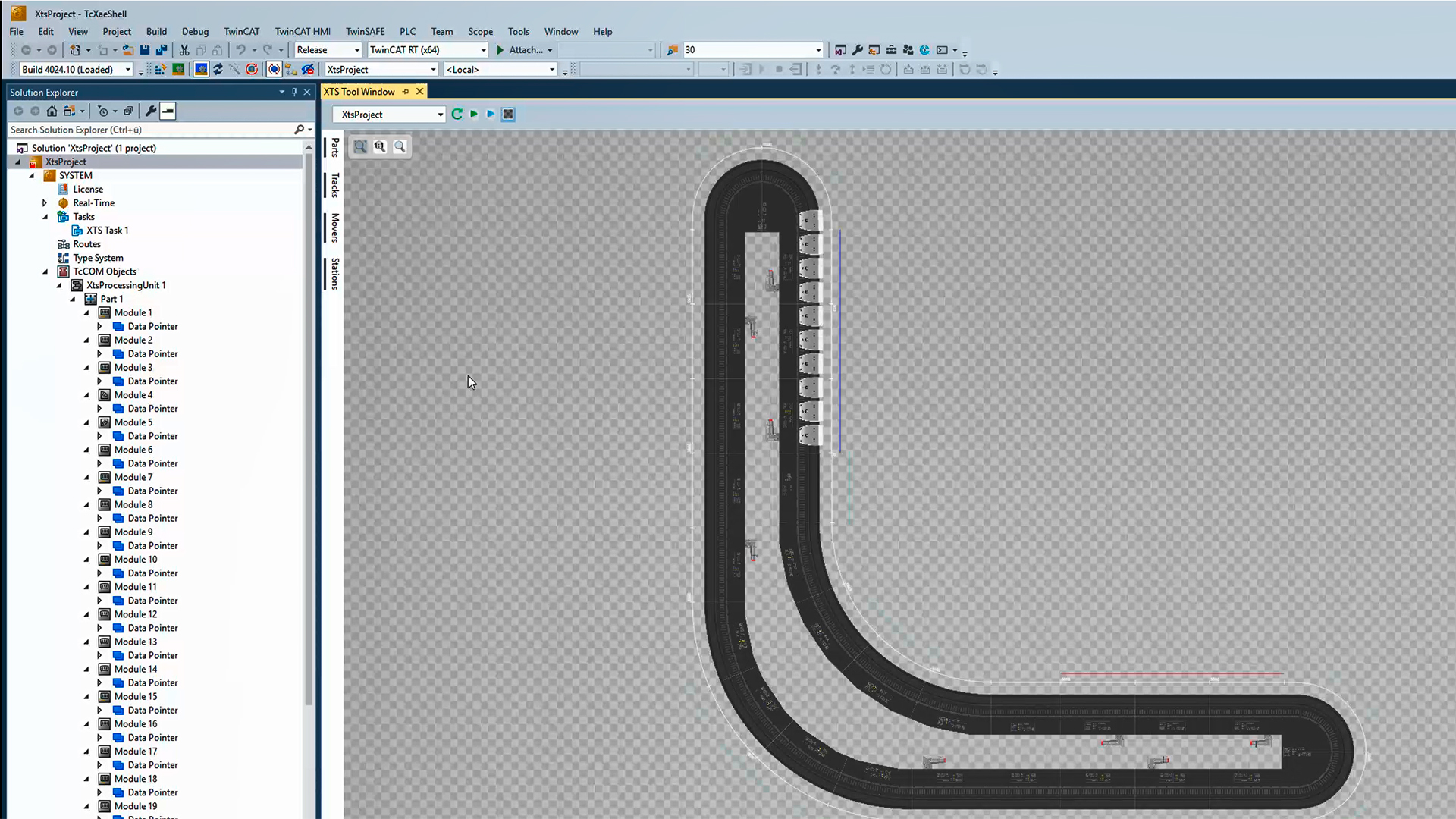

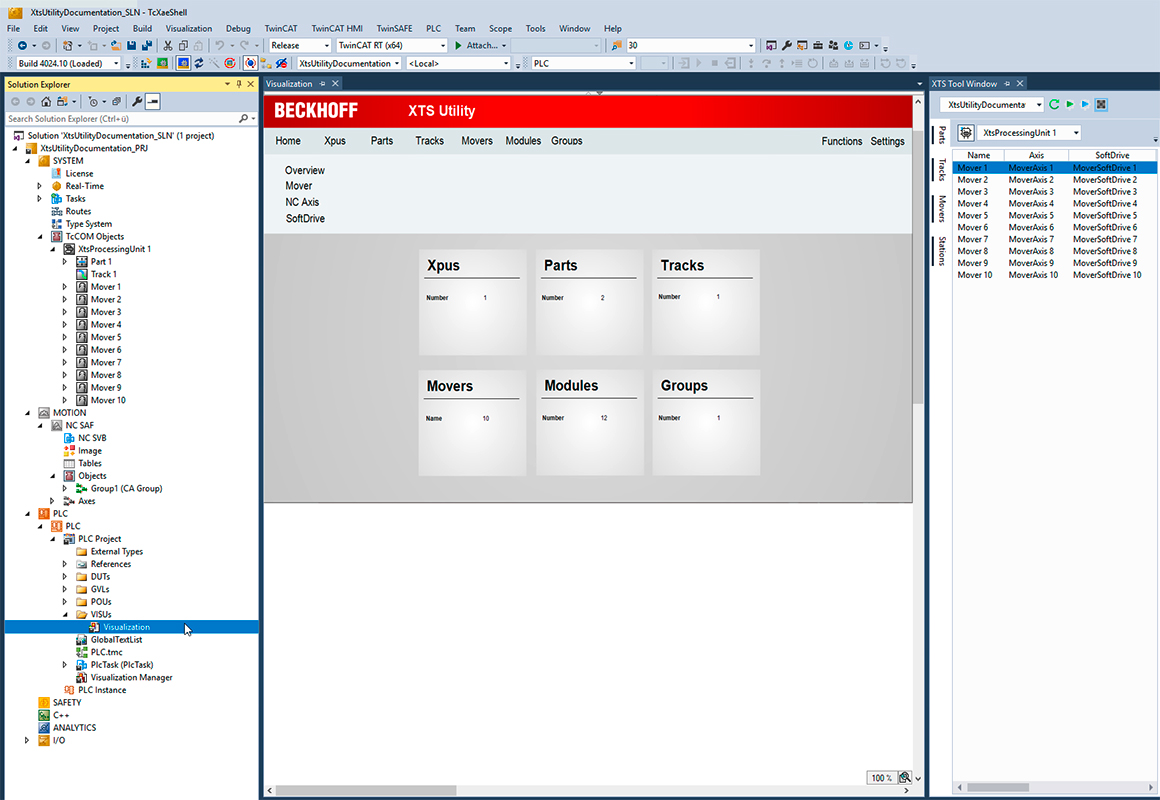

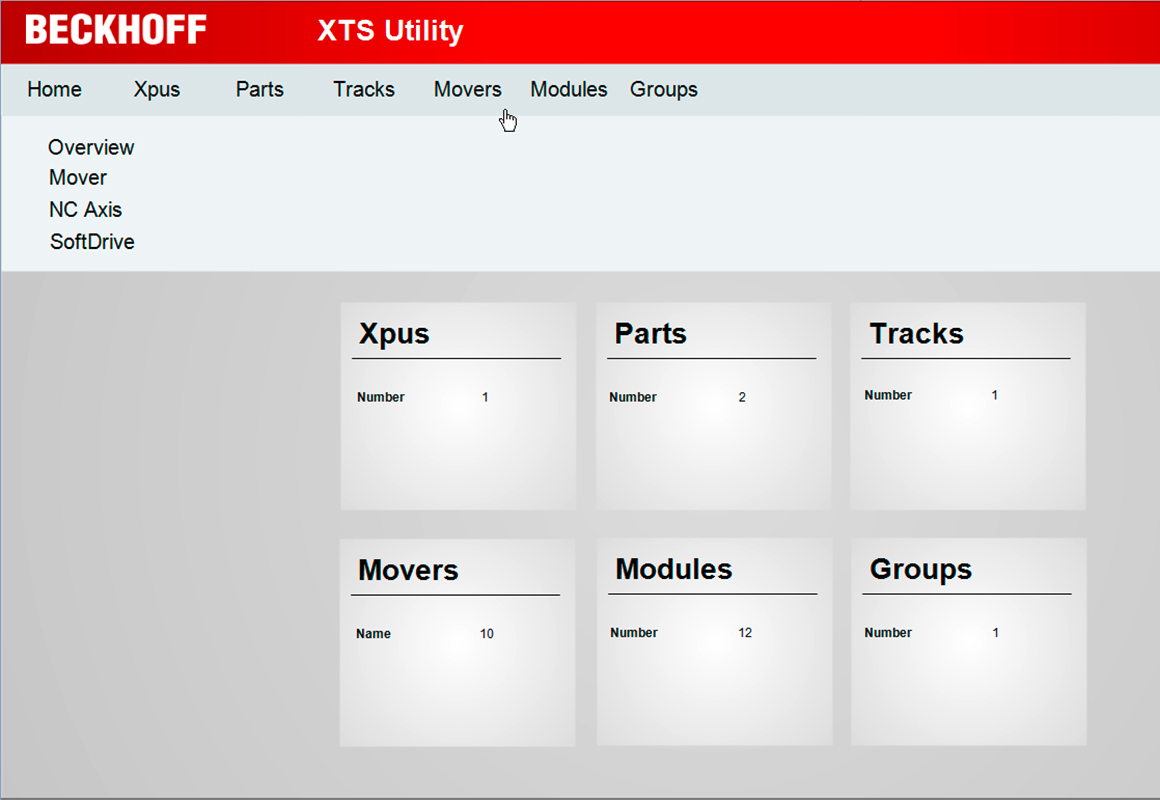

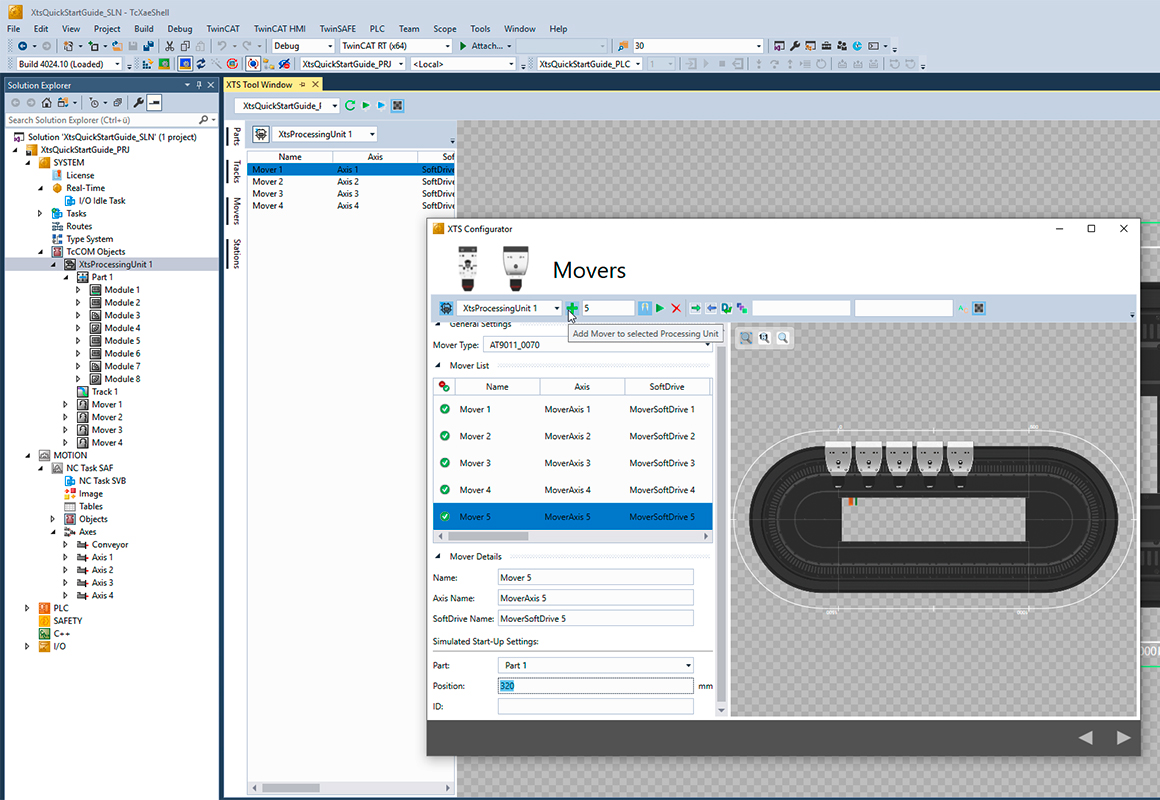

Beckhoff simplifies the project planning of the XTS applications with various software tools. The software tools are already included in the range of functions of the XTS software. An XTS Tool Window summarizes all components in a clear display and is the central point of contact for the user. Useful functions include

- the XTS Simulation Builder for creating track layouts and generating simulation projects,

- the XTS Configurator for setting up and parameterizing the hardware,

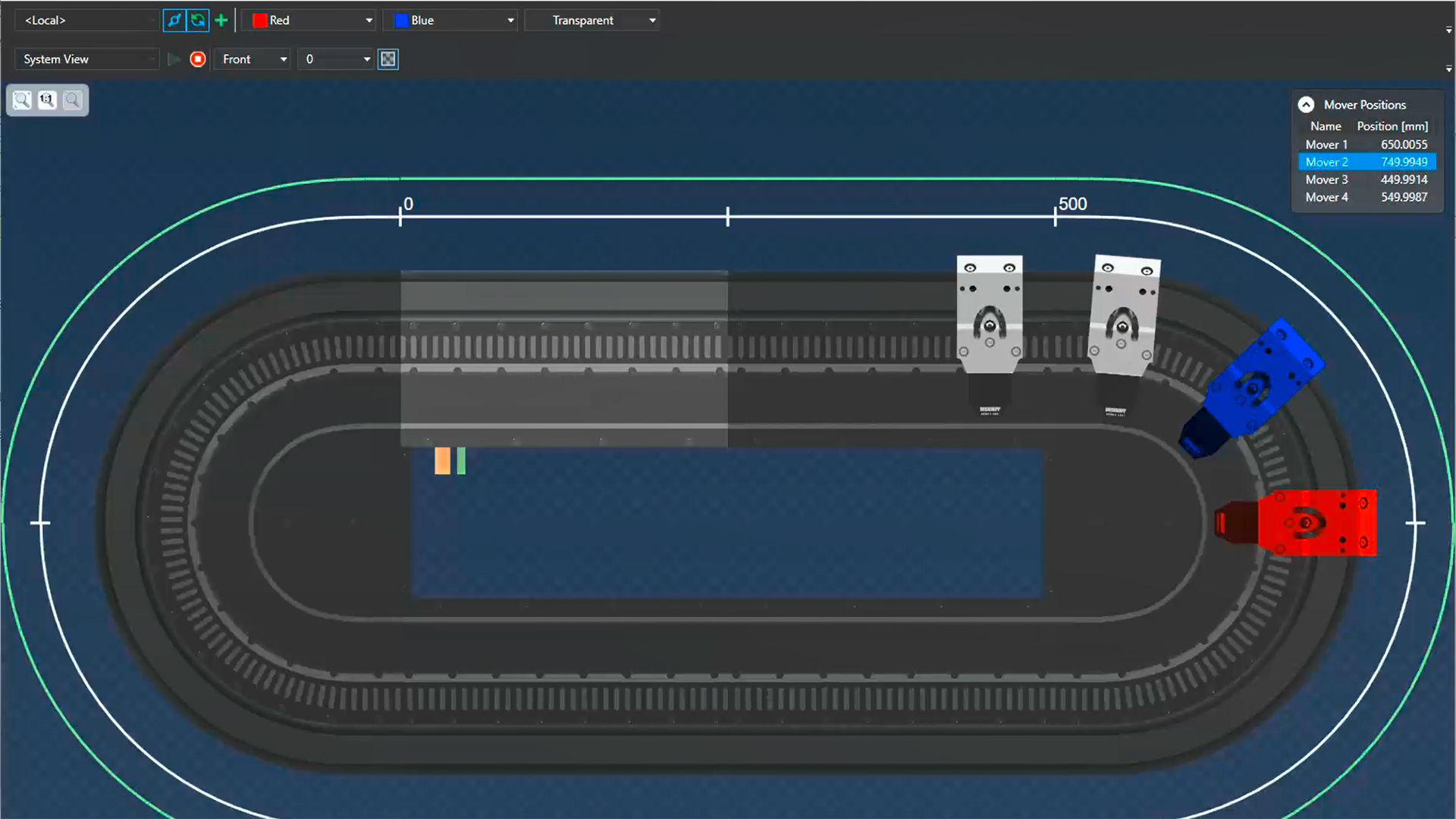

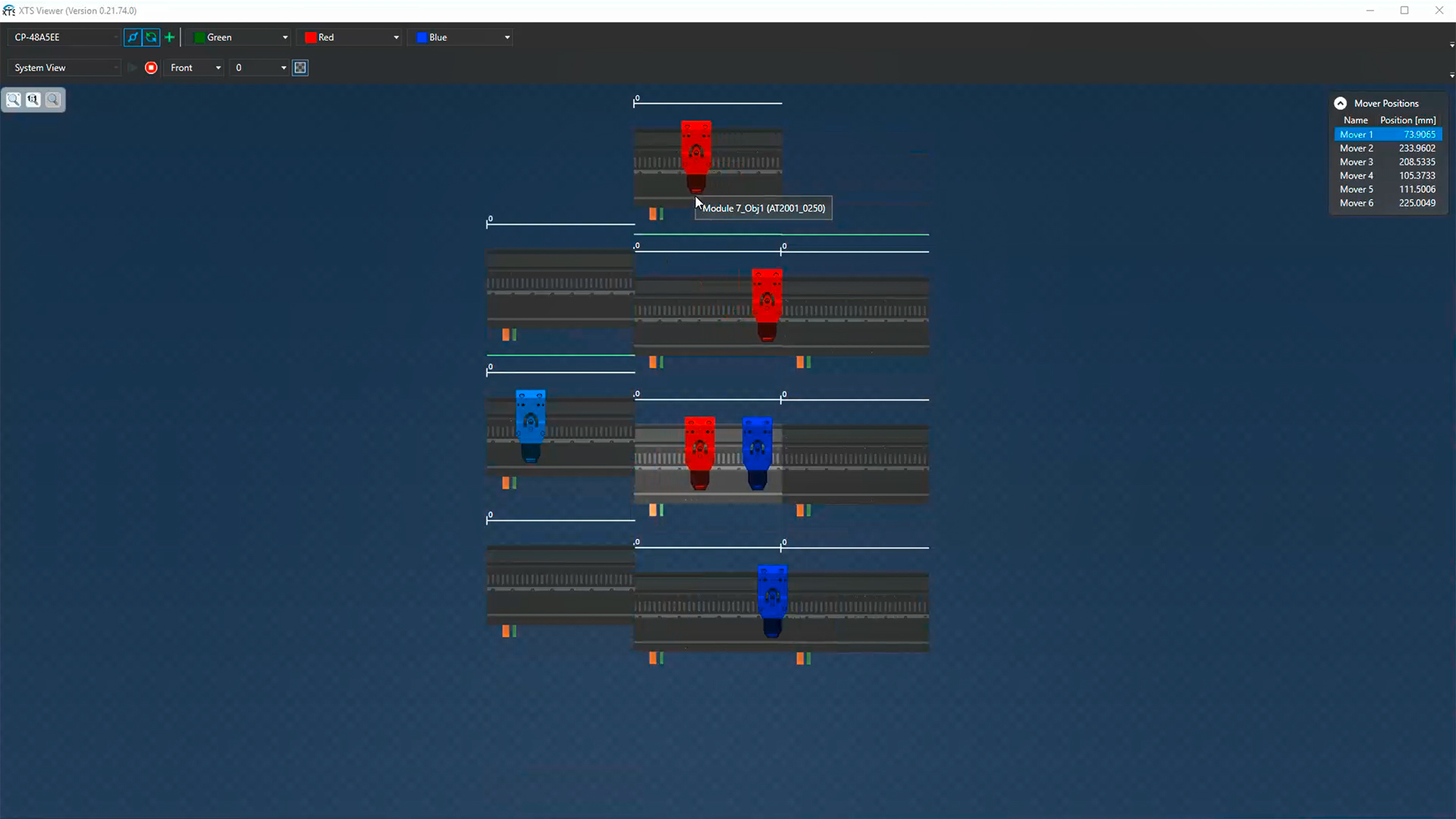

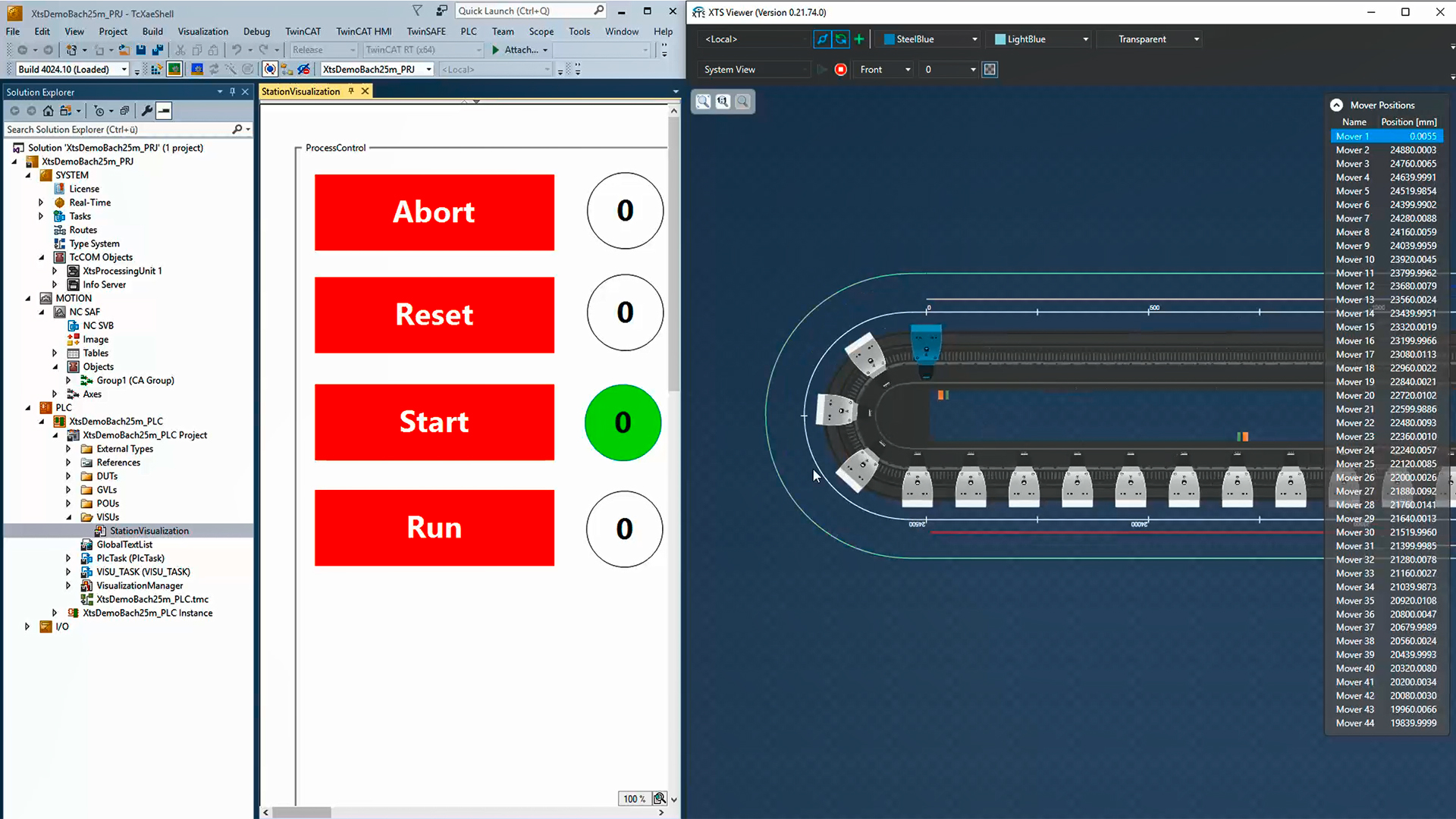

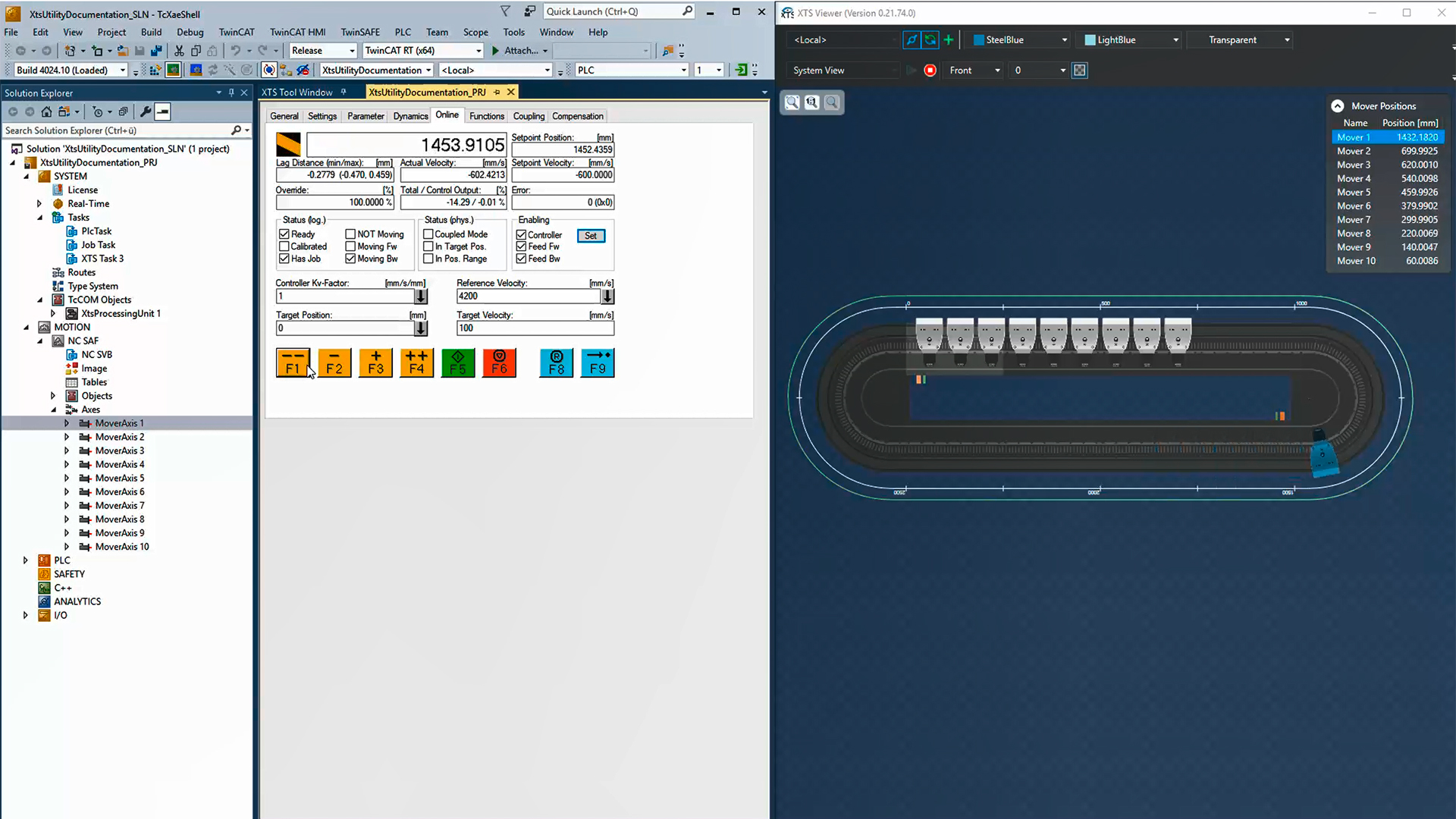

- the XTS Live View and XTS Viewer for the graphical view.

The XTS Configurator and the XTS Simulation Builder guide the user through the parameterization of the XTS application with visual support. Thus, movement of the XTS movers – on the hardware setup or in simulation – is possible after only a few minutes.Thanks to the integrated XTS Live View, it is particularly easy for the user to visualize the entire system and to understand program sequences. Due to this and the built-in diagnostic functions, errors can be rectified promptly and quickly. The flawless running of the application can thus be verified with particular ease. With the help of the XTS Viewer, the movements of the XTS movers can be observed in real-time on the display. The user does not need to be near the system. Simple functions, even with many XTS movers, always help the user to keep an overview and thus to track each movement individually.

Motion function blocks reduce engineering work

Depending on the XTS application, different motion profiles are required, from simple linear movements to highly complex sequences. The implementation of these movements is particularly convenient for the user due to prefabricated function blocks. It is advantageous here that a mover behaves like a servo axis in the engineering. All established motion control functions can be used, e.g. flying saw, electrical gears and cam plates. Function extensions are available to meet typical XTS requirements. These include

- automatic collision avoidance of the XTS movers,

- simplified synchronization movements,

- the use of physically shifted track layouts and

- the use of special features, such as XTS Track Management or Leave and Arrive.

Another system-related advantage is created by the diagnostics of the XTS hardware and software components. Many system parameters are already available in TwinCAT without additional sensors and can easily be analyzed using the integrated library of function blocks.

TwinCAT 3 Functions

The XTS functionalities described are summarized in the TwinCAT extension TF5850 | TwinCAT 3 XTS Extension. This also includes a license for the software extension TF5410 | TwinCAT 3 Motion Collision Avoidance for collision avoidance of the XTS movers.

TF5850 | TwinCAT 3 XTS Extension

The XTS linear transport system enables the individual movement of XTS movers along a specific track layout. The TF5850 XTS extension is the basic software package for the use of the XTS and its integration into the TwinCAT 3 environment. The user can continue to benefit from the extensive possibilities of TwinCAT and the XTS. The setup includes all the drivers and tools for efficient and intuitive working with the XTS.

TF5410 | TwinCAT 3 Motion Collision Avoidance

TwinCAT 3 Motion Collision Avoidance is an optional package that prevents collisions when operating a number of linearly and/or translationally dependent axes with TwinCAT 3 NC PTP. The underlying algorithm ensures the maintenance of a minimum distance from the previous axis. In this way, TwinCAT 3 Motion Collision Avoidance actively prevents collisions when a number of motors are using e.g. the same rail. As well as active collision avoidance, TF5410 can also be used to allow axes to accumulate in a controlled way, for example when carrying out linear movements such as with XTS (eXtended Transport System).