Products

Variable frequency drives

The compact, highly integrated variable frequency drives are particularly good for performing basic drive tasks cost-effectively.

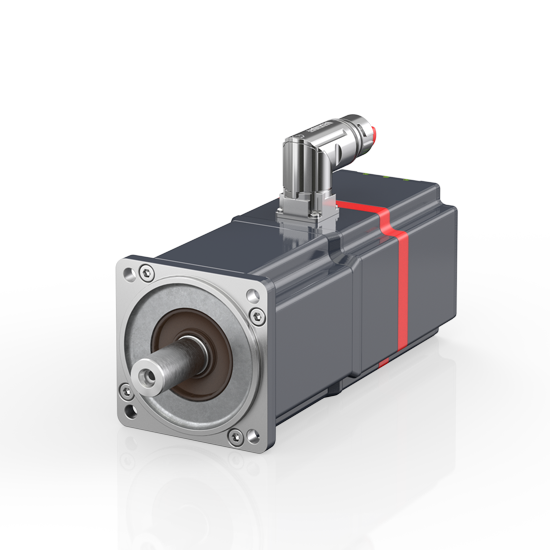

Servo drives

Compact stand-alone, double-axis or multi-axis servo drives for any application – TwinSAFE and multi-feedback interface are optionally selectable.

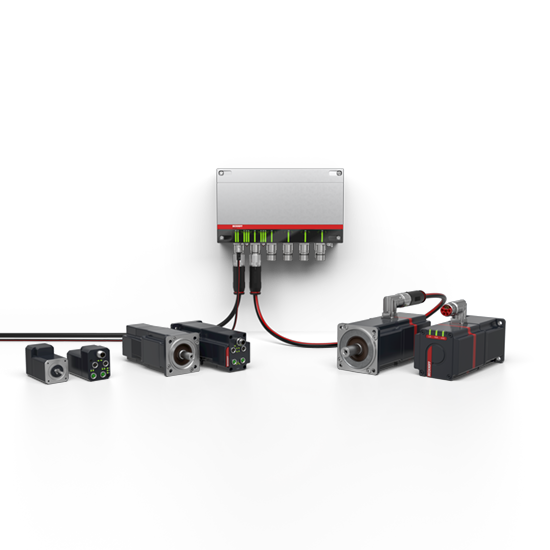

Distributed drive systems

These highly efficient drive systems for modular and control cabinet-free machines combine the servo drive and motor in a single unit.

Rotary servomotors

The scalable series of permanent magnet-excited synchronous motors are suitable for a very wide range of applications.

Planetary gears

The low-backlash precision gear units in straight and right-angled designs with various output flanges are optimally matched to the synchronous servomotors.

Translatory servomotors

The direct drives are particularly suitable for applications with the highest requirements for dynamics, positioning accuracy and synchronism.

Compact drive technology

The small drives in the low-voltage range offer solutions for both conventional operation and operation without a control cabinet.

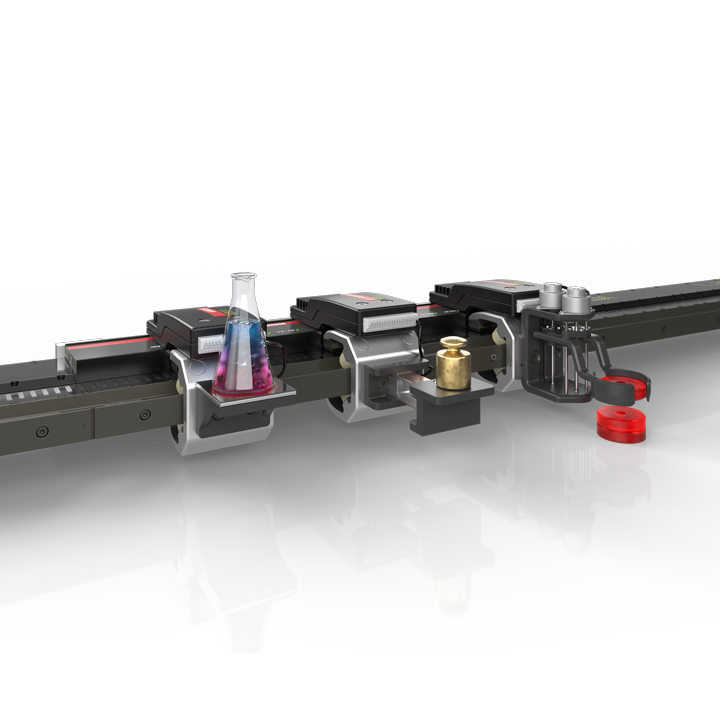

XTS | Linear product transport

As an intelligent transport system, the eXtended Transport System enables flexible motion profiles and new types of machine concept.

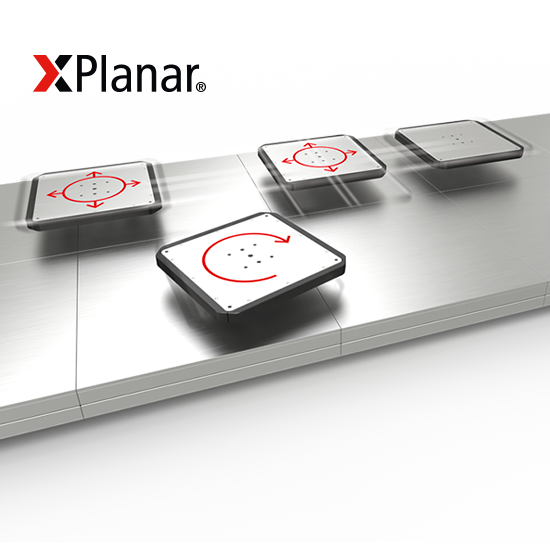

XPlanar | Planar motor system

Multi-mover 2D product movement with up to six degrees of freedom – floating, contactless, and intelligent.

ATRO | Automation Technology for Robotics

The ATRO system offers a unique, modular, and flexible industrial robot system that is fully integrated into the Beckhoff automation system.

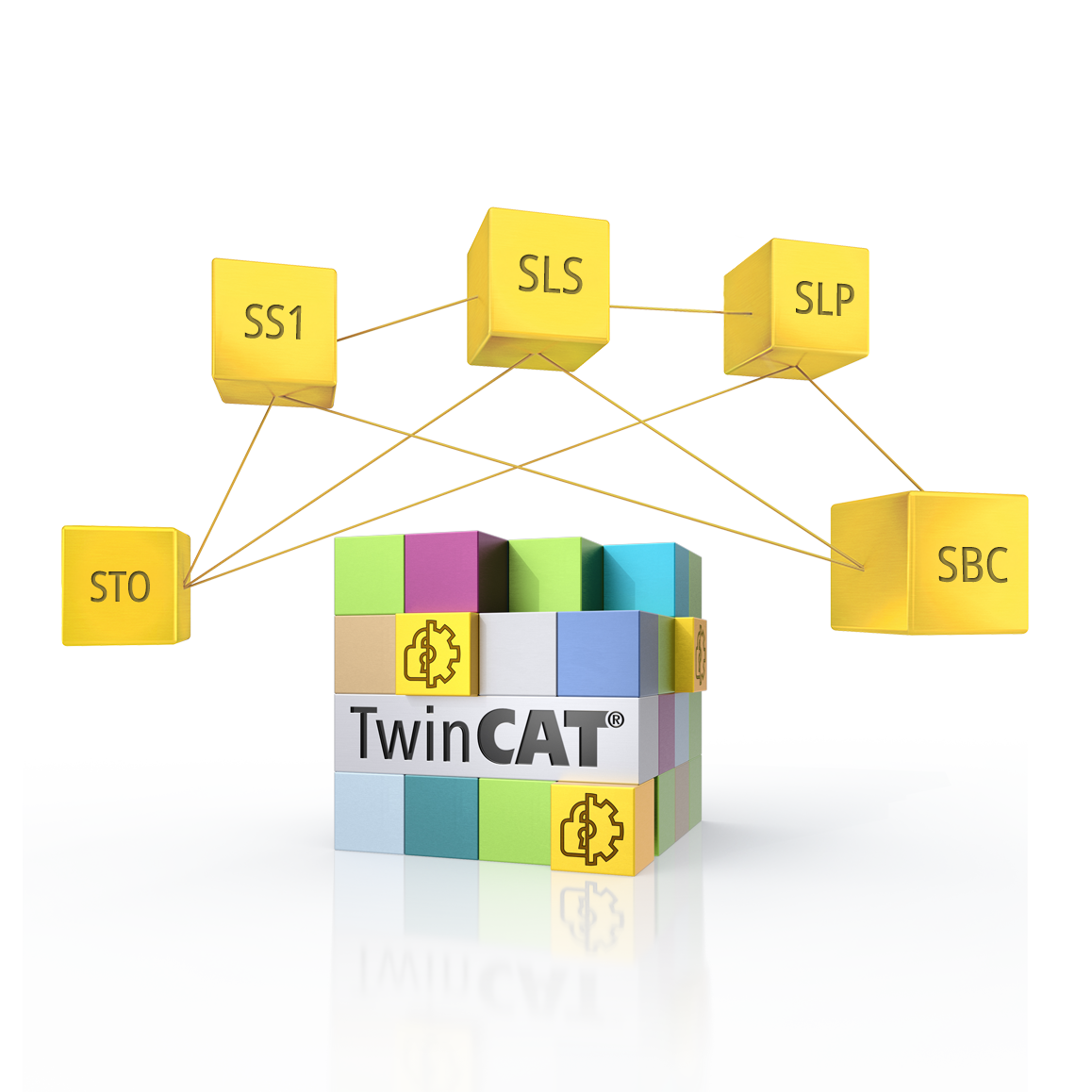

TwinSAFE safe drive technology

With the TwinSAFE safe automation technology, both basic functions and complex safety functions are available for all our drive solutions.

Accessories

All drive solutions can be optimally supplemented with our complete and field-proven portfolio of accessories.

Highlights

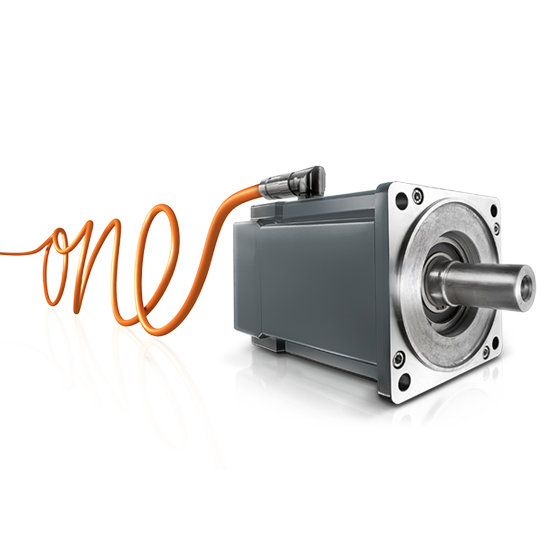

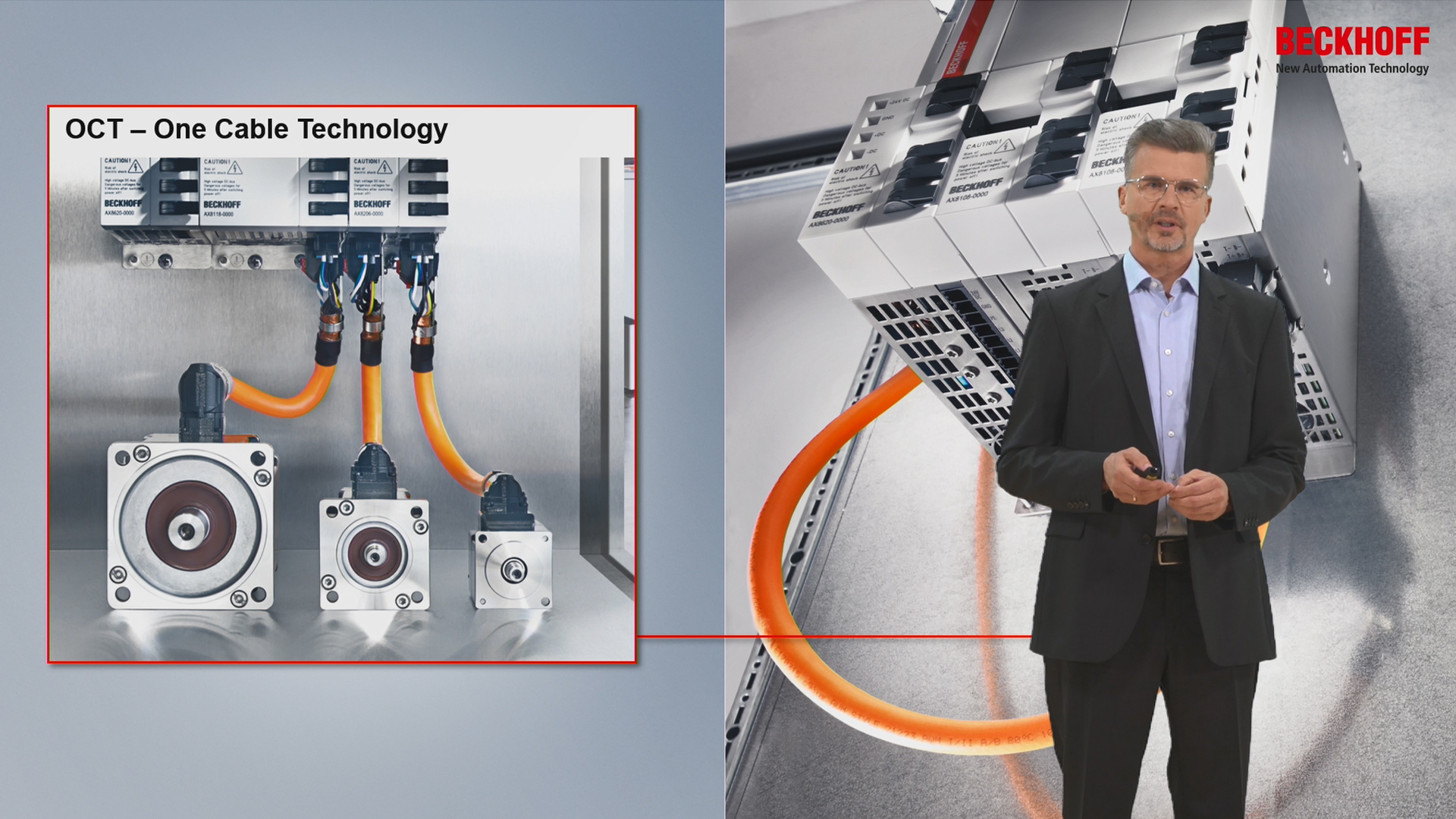

OCA | One Cable Automation

One Cable Automation facilitates efficient and optimal cabling for devices, machines, and systems.

Distributed drive systems

Distributed drive systems for control cabinet-free machine concepts

The innovative drive package

The innovative Beckhoff drive package offers a complete range of solutions for every application area. The integration into the motion control system of the TwinCAT automation software is thus optimized for highly dynamic positioning, extremely accurate machining, and efficient motion profiles. Developed by Beckhoff back in 2011 and established on the market, One Cable Technology (OCT) offers the machine manufacturer a space and cost-optimized alternative to conventional 2-cable wiring.

Use the Beckhoff drive technology expertise for your demanding application

Well-founded expertise built up over decades and a passion for electric drive technology form the basis for innovative solutions that give customers a technological advantage over competitors. Beckhoff supports the user in the drive design of his application as well as in the selection of the optimal drive components, including the appropriate accessories, and offers professional support during the commissioning phase. Moreover, Beckhoff continues to be at its customers' service as a reliable and competent partner, even if the machine has already been in service for a long period of time.

Drive technology "Made in Germany"

The extensive Beckhoff portfolio of highly scalable drive components is developed and produced exclusively in Germany. In addition to the Verl production site, the mechanical drive components have mainly been manufactured in Marktheidenfeld since 2010. A very high quality standard is ensured by state-of-the-art manufacturing technologies and extensive testing, including comprehensive traceability. The high manufacturing depth – in combination with reliable cooperation with suppliers – ensures the flexibility and short response times necessary to meet customer requirements.

Planning security due to long-term availability

Beckhoff products are designed for long-term, stable availability. At the beginning of product development, the components used are checked for their status in the life cycle before they are released for use. Constant monitoring of the component market for second source types ensures the long-term use of the products in standard machines.

Trendsetting and always one step ahead

In constant dialog with customers, Beckhoff is continuously expanding its drive technology portfolio and developing the right products for innovative machines.

TwinSAFE safe drive technology

Apart from aids for purely functional automation, Beckhoff provides a comprehensive solution for the field of safety technology in TwinSAFE. Safe drive functions can be realized in all areas of drive technology with TwinSAFE. This ranges from simple TwinSAFE STO functionality to complex safe drive functions (TwinSAFE Safe Motion) such as speed and position monitoring, which can be adapted flexibly and with fine granularity to the respective application requirements through the integration of the TwinSAFE logic directly into the drives.

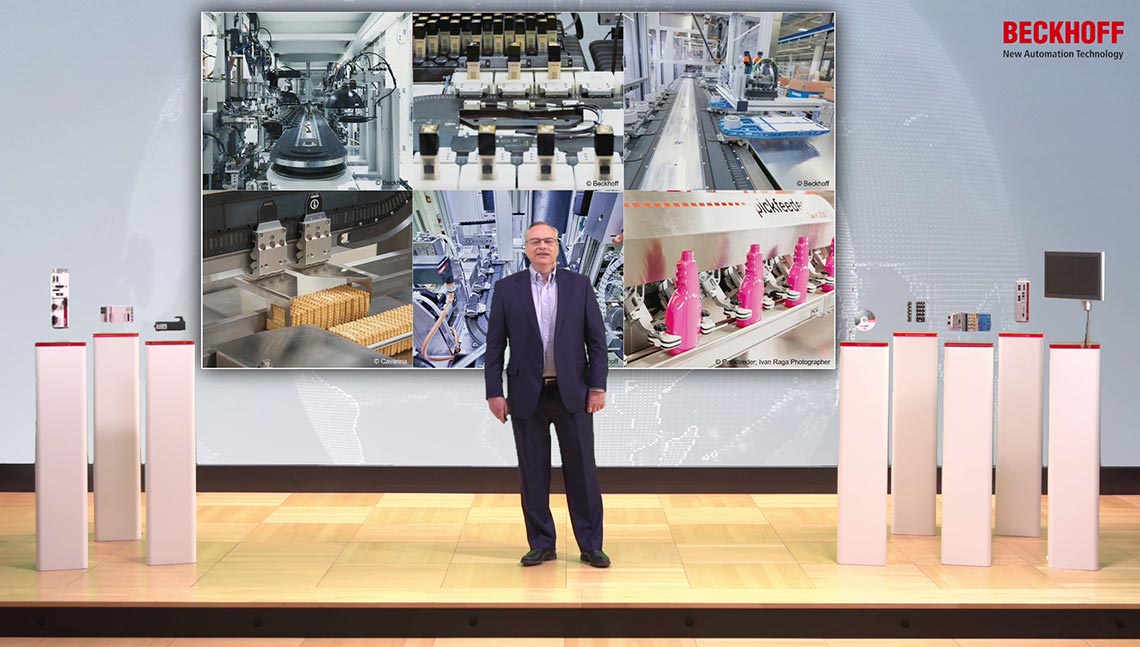

Intelligent handling systems

Volatile demand, a growing individualization trend and countless other factors are presenting the automation industry with the challenge of rethinking production processes. Rigid, clocked systems with the highest mechanical complexity are being replaced by flexible and intelligent machines. However, intelligence does not begin with the evaluation of production data in the cloud. It starts long before that, when the product travels through the machine with the help of an intelligent handling system.

Software replaces mechanisms

A key feature of intelligent handling systems is that they replace complex mechanisms with software-based solutions. The prerequisite is a hardware platform that enables free movement. These free movements can be cleverly combined by software. The intelligent handling system provides the user with processing options that would require the use of additional hardware in classic conditions. Complex 6-axis robots can thus be replaced with a simple feeder, and the handling system takes over the positioning tasks of the robot in the processing station. In addition, the software-based approach allows new functions to be added to the system by means of updates – entirely without any redesign.

Individual movement instead of clocked processes

The order of visiting the individual processing stations as well as the routes between them are rigidly dictated in conventional handling systems. Production cycle and product spacing are set once and optimized for a specific product. An intelligent transport system overcomes these limitations. Stations can be driven to in a selectable order via different paths – in a highly dynamic or energy-saving manner, depending on the requirements. This new flexibility enables the user on the one hand to load his machine according to requirements and on the other to produce different products on one plant with minimal changeover times.

Minimized space requirements

Intelligent handling systems not only replace mechanisms, but also contribute to the reduction of space requirements through their application-specific layout. A modular system with many different, combinable standard components allows the design of individual solutions. The user gets a tailor-made handling system – without expensive overheads.

The innovation advantage

As an automation expert, Beckhoff offers two intelligent handling systems that set standards. The XTS offers maximum freedom in one dimension and high dynamics. Non-contact product handling with up to six degrees of freedom is possible with the floating XPlanar.

ATRO: Automation Technology for Robotics – the modular industrial robot system

The ATRO system from Beckhoff is a modular industrial robot system that can be used to assemble the optimal robot structures for different applications on an individual and flexible basis. Standardized motor modules with integrated drive functionality, together with link modules in various designs and lengths, enable almost limitless combinations of mechanics. The complete integration of the control into the holistic control platform TwinCAT offers direct access to a wide range of proven automation functions.

Complete integration into the control platform

The benefits of the holistic system concept are twofold: Firstly, it features optimally matched software and hardware components from a single source. Secondly, all functions such as robotics, vision, safety, cloud robotics, and machine learning are fully integrated on a single control platform.

Modular design with standardized interfaces

All modules feature an internal media feed for data, power, and fluids (vacuum, air, and water), which are made available via the ATRO interface at the end effector. This means, for example, that a wide variety of tools, such as mechanical, pneumatic, or electric grippers, can be integrated with ease. Another major advantage is that all media feeds are designed in a way that preserves the endless rotation of the axes and the tool.

What are the benefits for your overall system?

Expanding the Beckhoff control platform with robotics means that machine builders and customers can secure a complete automation solution from a single source. What’s more, the integration into the Beckhoff system architecture means users now only need a single control system for all robot applications. The link with XPlanar and XTS, as well as the simple integration of all Beckhoff components into the robotics system, lays the foundations for entirely new machine concepts. The open control architecture increases investment security, while the EtherCAT technology also opens the door to real competitive advantages.