Food packaging requires high-quality, flexible and resource-saving solutions. In addition to ever smaller production batches and increasing production speed, traceability and complete electronic process documentation and validation are becoming increasingly important. With PC-based Control, Beckhoff offers a control solution for highly efficient, flexible and compact filling and packaging machines. PC-based Control is particularly suitable for applications in which high speed and precision are required or where complex motion connections have to be implemented. Maximum flexibility is guaranteed in situations where packaging systems are to be adapted to changing requirements without high implementation costs or if new functionalities are to be seamlessly integrated.

TwinCAT is the integrated software and engineering platform for all automation processes, including PLC, Motion Control, robotics and Condition Monitoring. All control and drive components are fully scalable in terms of performance and design. Open interfaces in hardware and software ensure continuous communication from the sensor to the cloud. Further advantages include the integrated safety solution and support of common industry standards such as FDA, EHEDG, Weihenstephan standards, OMAC and GPM.

Application reports and brochures

- 04.11.2024 | Application report

The “magic machine”: a software-enabled, highly efficient and reliable capping application

Tetra Pak, ItalyThe typical beverage cartons that Tetra Pak produces for milk, fruit juices, and more are familiar to virtually all of us. Although they are efficient and robust to transport and use, they place significant demands on production technology. Key to the company’s processes are quality, system output, and process flexibility – and the Development & Technology experts at Tetra Pak in Modena, Italy, have used the XTS linear transport system from Beckhoff to achieve all of these in a new machine for cap application onto carton packaging. The system has been so successful that Tetra Pak’s pilot customer, impressed by its reliability, performance, and flexibility, has described it as a “magic machine.”

- 06.06.2024 | Brochure

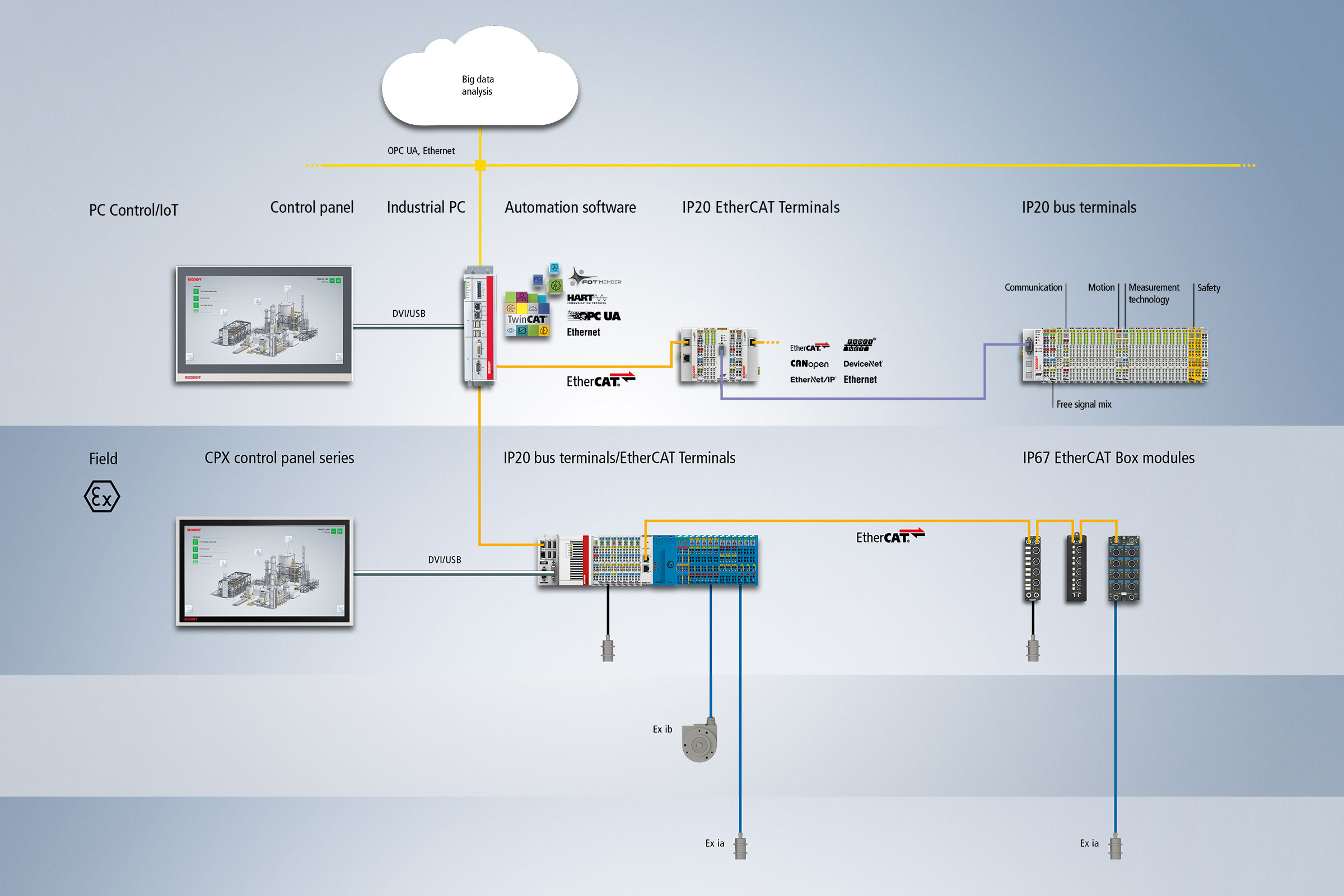

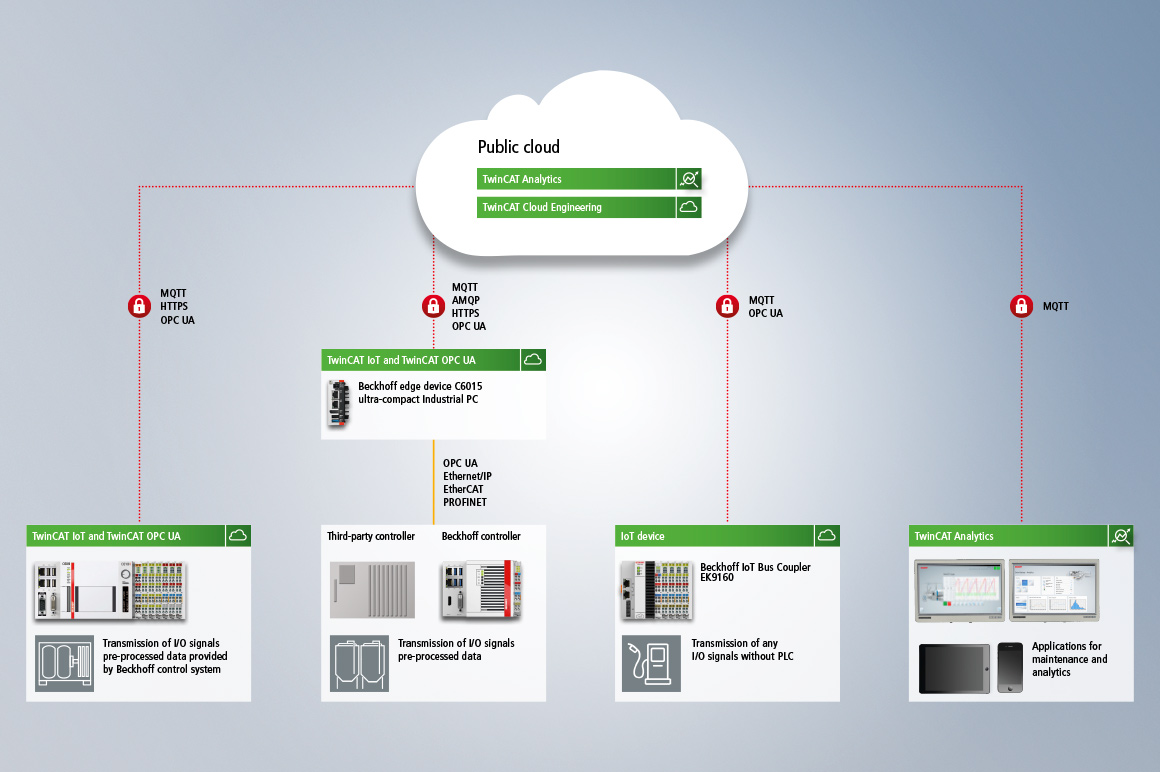

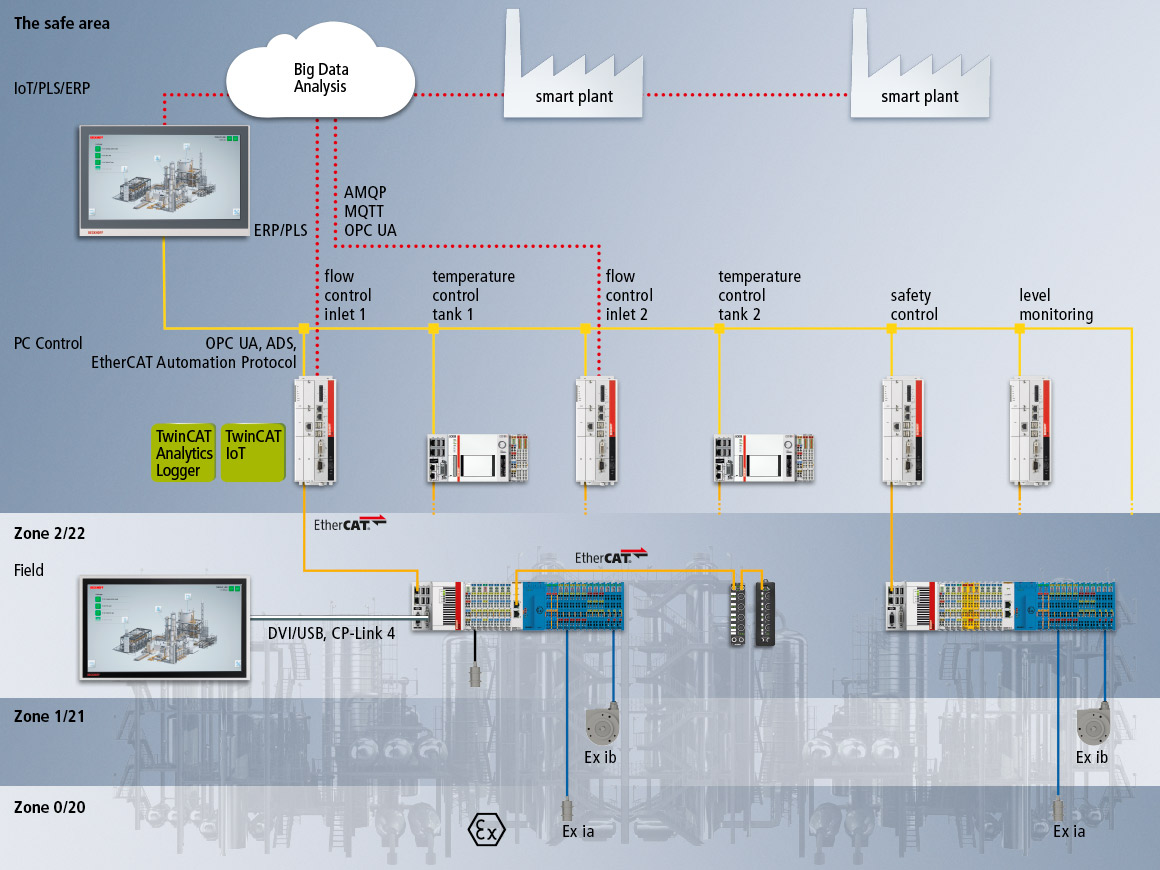

The control system for process automation: PC-based control

Beckhoff offers open automation solutions for the process industry: PC-based control provides a universal control system that can be used to automate all plants and processes.

- 17.07.2023 | Application report

Control technology for round-the-clock food provision which offers true convenience

Delfin, PolandThe fully automated Zinu Shop convenience store operates 24 hours a day, seven days a week, all year round. It was developed by Delfin, which has been supplying small communities in Poland with general goods for more than 20 years. The project launched in 2017, with the first full-scale, open tests taking place just four years later – including those on the underlying PC-based control technology from Beckhoff.

- 17.07.2023 | Application report

From the kitchen into the cloud – Digitalization recipe for the pancake of tomorrow

CTRL Engineering und Yummy Bakery , BelgiumYummy Bakery’s pancakes are “hot” and end up on the shelves of virtually every major retail chain in Belgium. The secret behind this success? Using the authentic ingredients and preparation method on a baking plate. A recipe that perfectly combines with digitalization as CTRL Engineering successfully demonstrated. Besides 7 to 8% raw material savings, the automation of dough dosing with control technology from Beckhoff also helped provide data for ongoing process optimization.

- 17.04.2023 | Application report

High-performance motion control increases flexibility and machine speed

Teepack, GermanyDid you ever stop and think about how tea gets into those tiny bags, or how the leaves stay inside when brewed? Teepack has been doing exactly that since 1948. In what they describe as their masterpiece – the Perfecta 450 – Franz Andel and Sascha Theine rely on PC-based control and drive technology from Beckhoff to set new benchmarks for speed and precision in their tea-bag packaging machines.