TwinCAT Motion Control: perfectly suited for all drive tasks in plastics technology

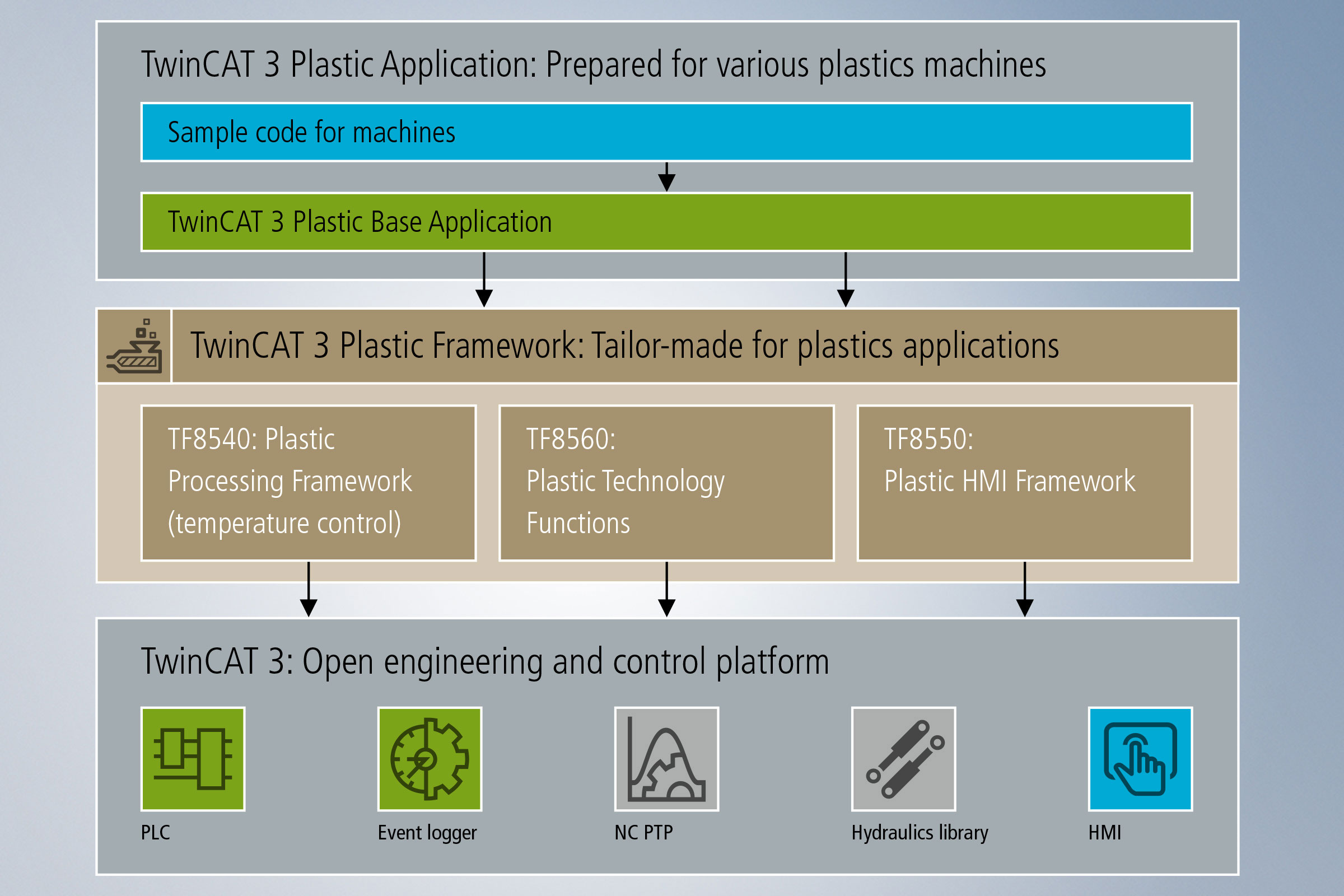

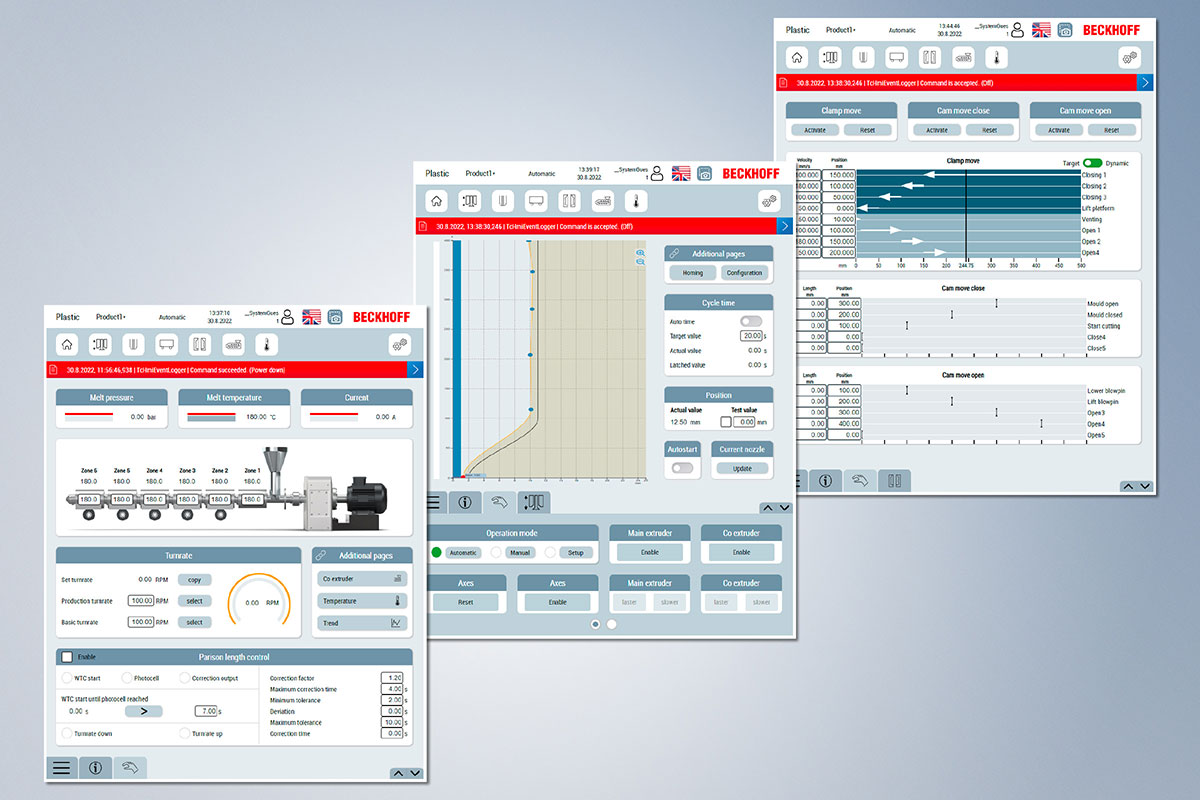

Motion Control has been an important part of Beckhoff's software engineering tools for many years. With TwinCAT PTP and TwinCAT NC I, the requirements of electric drive technology in plastics machines and their peripherals are perfectly covered. A wide range of software modules for different tasks such as cam plates, synchronization and interpolating movements of several axes are available. NC PTP is perfectly suited for the widely used Cartesian removal systems; integration into the machine controller of the processing machine is easily feasible. The TwinCAT Plastic Application Components are available for stand-alone handling applications. As an industry-specific extension of the TwinCAT, they support the widely used Euromap interfaces between injection molding machine and robot, either as Euromap 67 or in the future as Euromap 79 (OPC 40079).

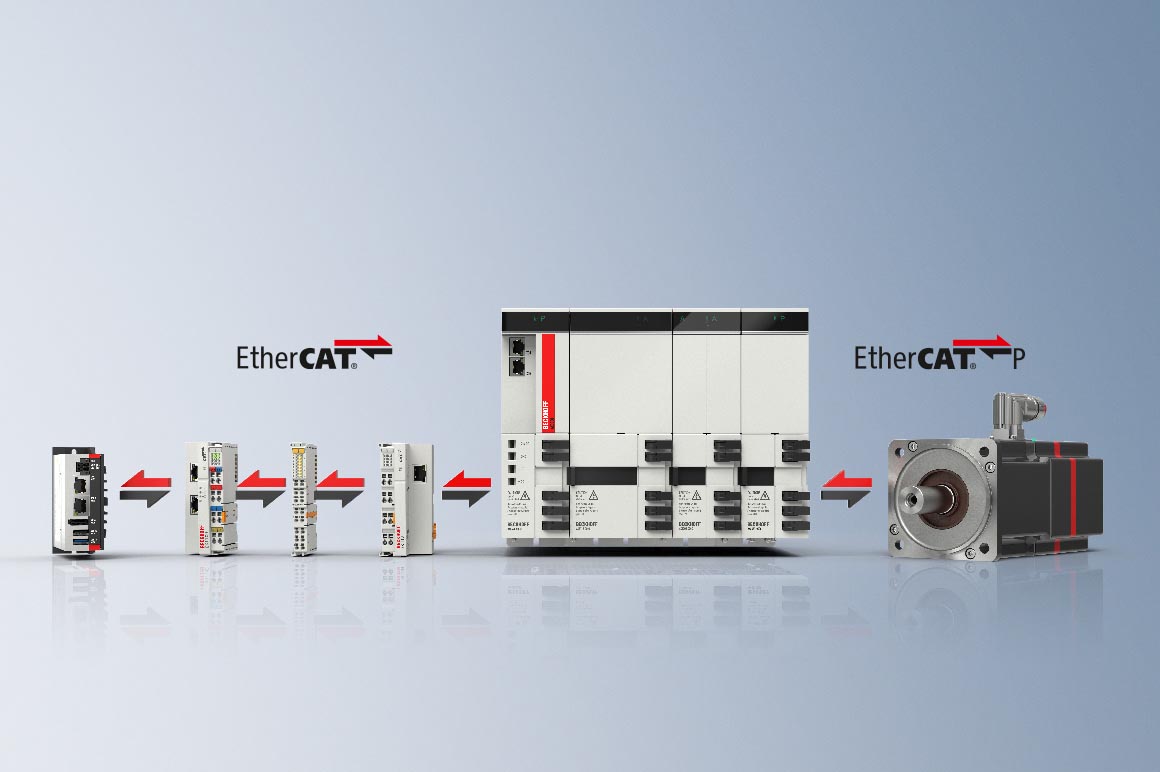

Fast removal processes, such as in-mold labeling with the help of side removal handling, are optimized with PC- and EtherCAT-based control technology: EtherCAT as a fieldbus with virtually delay-free synchronization leads to extremely short cycle times.

Following the philosophy of open automation technology, TwinCAT Motion Control is a tool for the design of production cells that allows the integration of Beckhoff drive components as well as third-party components. TwinCAT NC-PTP is a suitable engineering tool for a variety of drive concepts: from simple switched axes and stepper motors or frequency converters to servo drives.

Different encoder technologies with fieldbus interfaces or direct connection via I/Os are supported. This makes it possible to design production cells modularly, flexibly and at an optimal cost according to market requirements. In particular, the linking possibilities of master and slave axes in almost any structure as well as the powerful and diverse motion functions of TwinCAT cover wide-ranging applications in outstanding fashion. With the Flying Saw software library, for example, trimming units in extrusion lines can be perfectly synchronized. Powerful tools such as the TwinCAT CAM Design Tool and the TwinCAT Scope support machine design and commissioning. PLC libraries with function blocks according to the PLCopen Motion Control standard facilitate programming and save engineering effort through the reusability of the modules.