The one cable solution – one step closer to automation without control cabinets

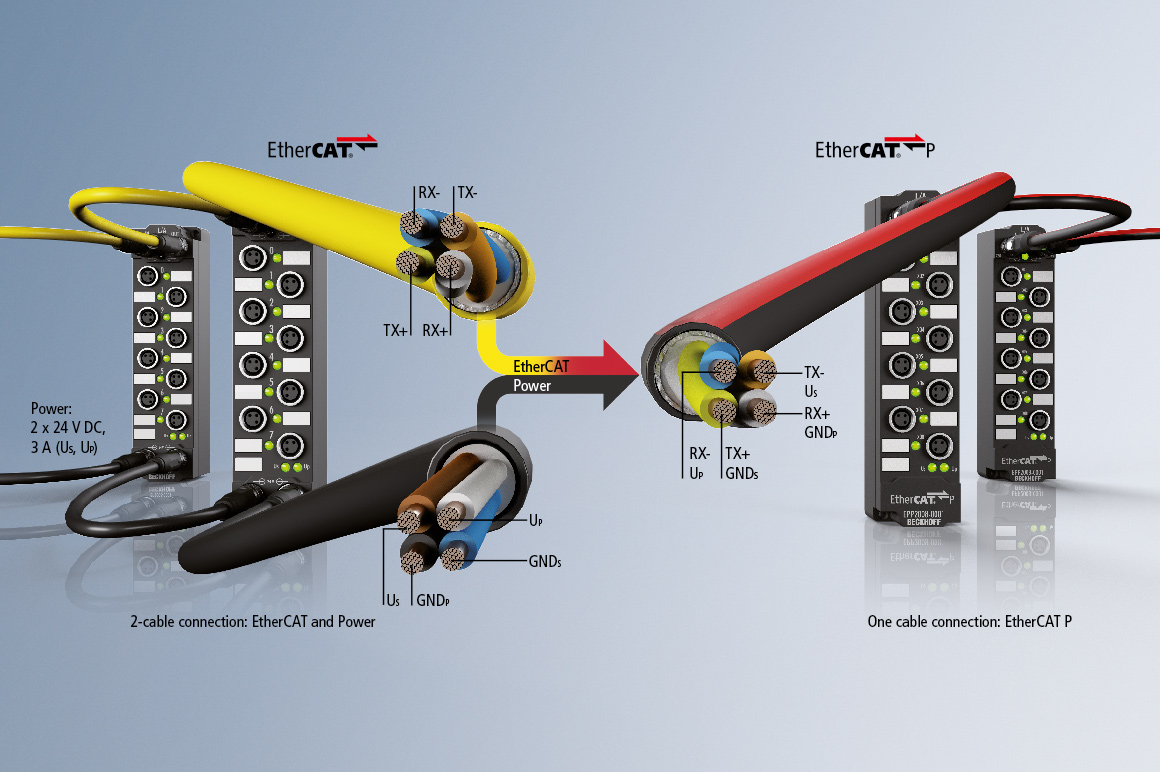

With EtherCAT P, Beckhoff combines communication and power in a single 4-wire standard Ethernet cable. The 24 V DC supply of the EtherCAT P slaves and of the connected sensors and actuators is integrated: US (system and sensor supply) and UP (peripheral voltage for actuators) are electrically isolated from each other and can each supply a current of up to 3 A to the connected components. At the same time, all the benefits of EtherCAT, such as freedom in topology design, high speed, optimum bandwidth utilization, telegram processing on-the-fly, highly precise synchronization, extensive diagnostics functionality, etc., are all retained.

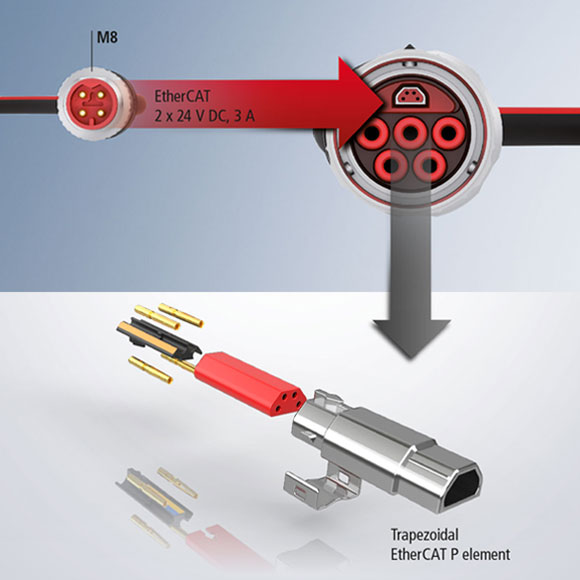

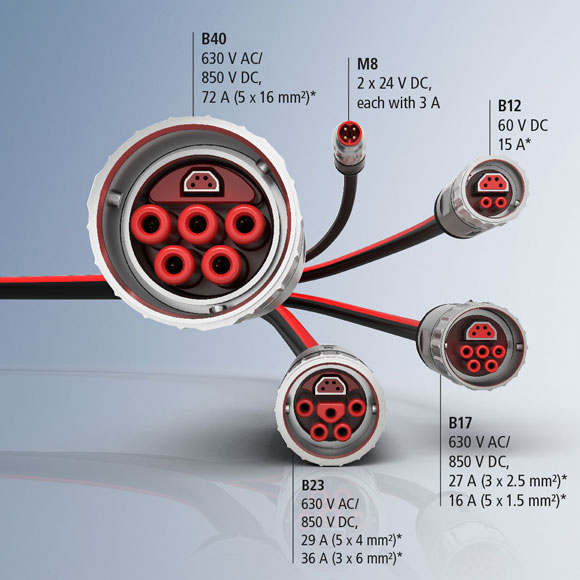

The currents of US and UP are coupled directly into the wires of the 100 Mbit/s line, enabling the realization of a highly cost-effective and compact connection. EtherCAT P offers benefits both for connecting smaller, remote I/O stations in the terminal box and for decentralized I/O components locally in the process. A connector family was specially developed for EtherCAT P, in order to prevent potential damage caused by incorrect connection with standard EtherCAT slaves. It covers all applications from the 24 V I/O level up to drives with 630 V AC or 850 V DC and a current of up to 72 A.

EtherCAT P offers extensive savings potential:

- optimized for direct connection of EtherCAT P devices in the field

- time savings through lower wiring effort

- fewer errors

- smaller sensors and actuators through the elimination of separate supply cables

- simple connection of components

As usual with EtherCAT, users benefit from the choice of topology and can combine line, star and tree structures with one another in order to achieve the least expensive and best possible layout of their system. Unlike classic Power over Ethernet (PoE), devices can be cascaded in EtherCAT P and supplied with power from one power supply unit.

When designing a machine, the individual consumers, cable lengths and cable types are configured with tool assistance and this information is used to create the optimum layout of the EtherCAT P network. Since it is known what sensors and actuators will be connected and which ones will be operated simultaneously, the power consumption can be accounted for accordingly. For example, if two actuators never switch simultaneously from a logical point of view, they also never need the full load simultaneously. The result is further savings potential in terms of the required supplies and power supply units.

Highlights, advantages and technical data

- compatible technology:

- 100% EtherCAT-compatible

- 100 Mbit/s full duplex

- processing on the fly

- high-precision synchronization with distributed clocks

- cascadable in all topologies (star, line, tree)

- dual power supply

- US (system and sensor supply) = 24 V DC/3 A, UP (peripheral voltage for actuators) = 24 V DC/3 A

- cost-reduction potential

- elimination of separate supply cables

- reduced material and assembly costs

- minimized installation space for drag-chains, control cabinets and machine footprint

- lowered connection costs with outstanding EtherCAT performance

- connectors and cables

- industrial Cat.5 cables in AWG22 and AWG24

- ultra-thin cables for short distances

- M8 P-coded according to IEC 61076-2-114

- easy assembly in the field

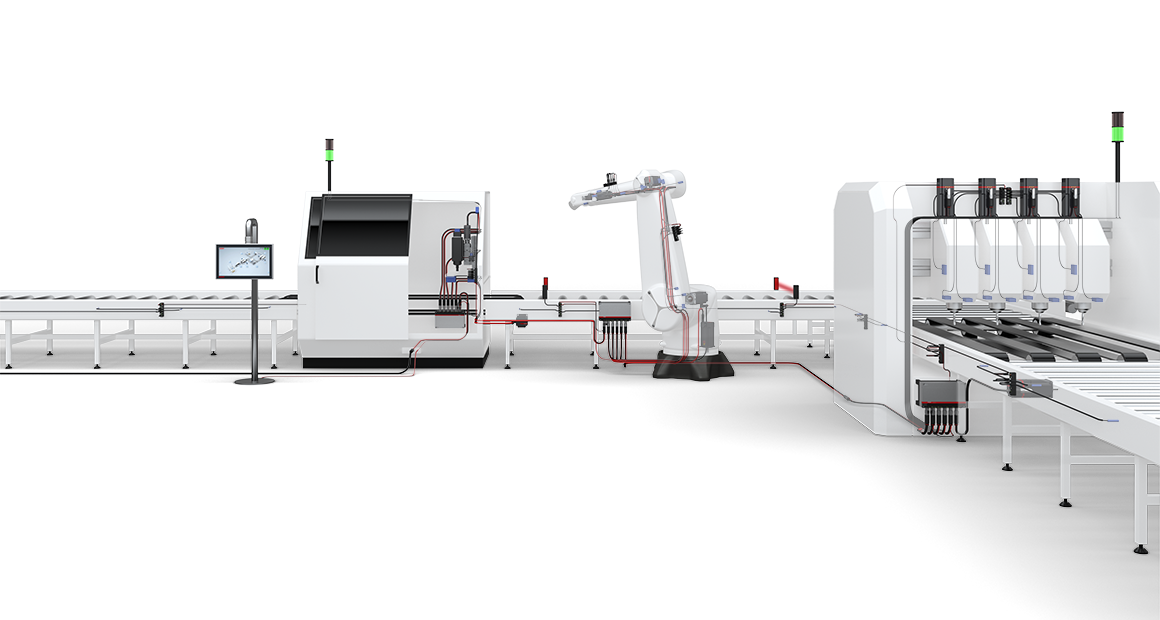

One Cable Automation for the field level

Application of EtherCAT P

The sensor, actuator and measurement bus

- optimized for direct connection of EtherCAT P devices in the field

- time savings through lower wiring effort

- fewer errors

- smaller sensors and actuators through the elimination of separate supply cables

- simple connection of components

EtherCAT P for actuators

- AC and DC motors

- actuators

- valve terminals

EtherCAT P for sensors

- proximity switches

- light barriers

- shaft encoders

EtherCAT P for vision

- cameras

- barcode scanners

- 3D scanners

EtherCAT P for I/O

- connections in IP67

- connections in IP20

System overview for IP20 and IP67

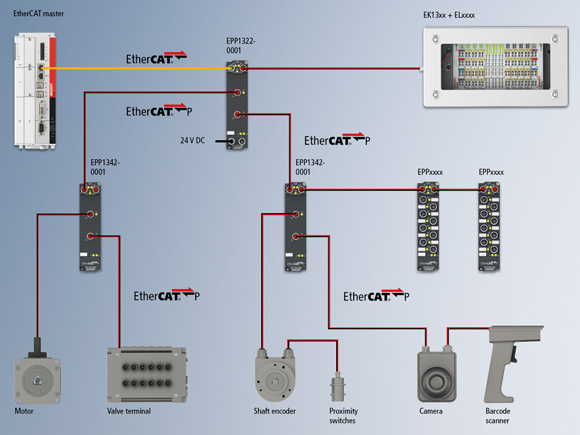

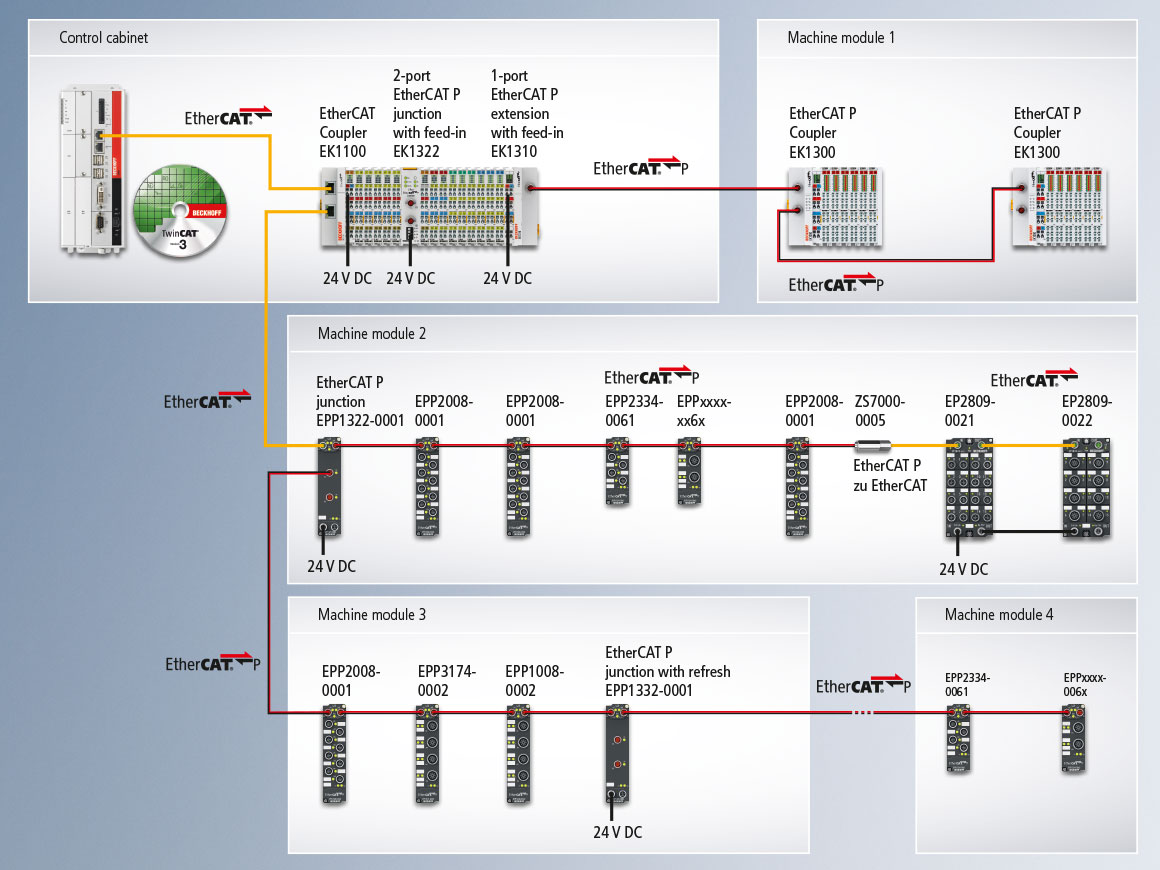

As usual with EtherCAT, users benefit from the choice of topology and can combine line, star and tree structures with one another in order to achieve the least expensive and best possible layout of their system. Unlike classic Power over Ethernet (PoE), devices can be cascaded in EtherCAT P and supplied with power from one power supply unit.

The EK13xx EtherCAT P Couplers with IP20 rating enable the use of EtherCAT P from the control cabinet right to the machine:

- the EK1300 coupler with a second M8 socket, P-coded, for continuation of the topology,

- the 2-port EK1322 EtherCAT P junction (with feed-in) enables configuration of EtherCAT P star topologies,

- the 1-port EK1310 EtherCAT P extension (with feed-in) enables conversion from EtherCAT to EtherCAT P.

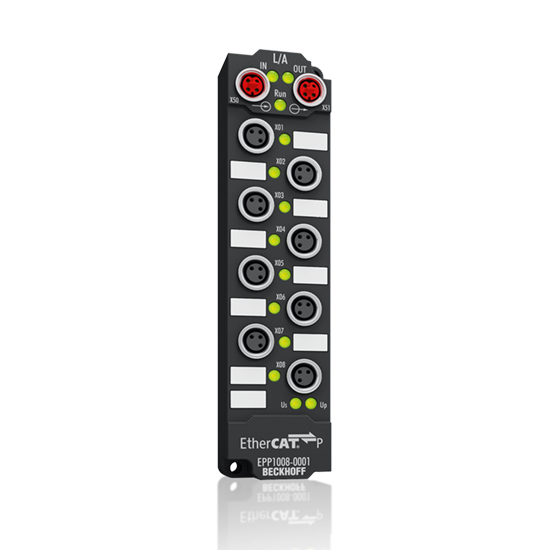

The EPPxxxx EtherCAT P Box modules with IP67 rating cover the typical range of requirements for I/O signals:

- digital inputs (3.0 ms or 10 μs filter),

- digital outputs with 0.5 A output current,

- combination modules with digital inputs and outputs,

- analog inputs and outputs with 16-bit resolution, thermocouple and RTD inputs.

The EPP13xx EtherCAT P junctions are available for flexible topology configurations. The current carrying capacity of 3 A per EtherCAT P segment already enables a wide range of sensors/actuators to be used. If a power supply boost is required, the EPP1332-0001 EtherCAT P junction can be used to feed in both US and UP at any point. The EPP1342-0001 should be used for branches without voltage refresh.

Matching connectors for every performance class – from the 24 V sensor to the 600 V drive

- The trapezoidal EtherCAT P element enables high packing density, resulting in improved current-carrying capacity and dielectric strength of the power pins.

- seamless and consistent 360° shielding of the connector

- uniform EtherCAT P element for all sizes B12…B40

- uniform construction across all sizes B12…B40

- bayonet connector for quick connect/disconnect

- shielded and unshielded (outer shield) variants available

- large variety of pin and socket combinations

- mechanical keying (2…6 mechanical keying positions available, depending on size and pole number)

- visual marking through colored rings possible

- thinner cables by reducing the number of wires per cable

- connectors for field assembly

- same design for all sizes

- simplified installation

- reduced assembly effort due to

- pre-configuration of the cable

- colored wires and matching identification in the connector

- poka-yoke principle for individual components

- flange socket with industry standard flange dimensions (front assembly, rear assembly and square flange)

EtherCAT P products

EK1300 | EtherCAT P coupler

The EK1300 EtherCAT P coupler integrates the EtherCAT Terminals into the EtherCAT P network. The coupler converts the passing telegrams from Ethernet 100BASE-TX to E-bus signal representation. A station consists of a coupler and any number of EtherCAT Terminals that are automatically detected and individually displayed in the process image

EK1310 | 1-port EtherCAT P extension with feed-in

The EK1310 EtherCAT P power supply offers the option of converting from an EtherCAT segment, which is configured via an EtherCAT Coupler or an Embedded PC from the CX series, to EtherCAT P or extending an EtherCAT P network in line topology.

EK1322 | 2-port EtherCAT P junction with feed-in

The EK1322 2-port EtherCAT P junction can be used in an EtherCAT Terminal segment at any desired position between the EtherCAT Terminals and enables configuration of EtherCAT P star topologies. A modular EtherCAT P star hub can be realized by using several EK1322 units in a station.

EPPxxxx | Industrial housing

IP67 modules with EtherCAT P: Communication and power in a single 4-wire standard Ethernet cable.

Hybrid cables

The combination of power supply, signal and data communication in one connector. Hybrid cables are available in application-specific sizes and performance classes.