In addition to Ethernet TCP/IP, serial protocols and OPC UA, the Beckhoff control platform supports all relevant protocols in the area of media technology. This includes Open Control Architecture (AES 70 standard), PJLink, SMPTE Timecode, Crestron, Bang & Olufsen, ArtNet™ and Streaming ACN (sACN), among others. Vendor-independent control of the widest range of media technology equipment enables the seamless operation of audio and video systems, display devices, multimedia servers and streaming services – in one network and on the same platform. The advantage for users is clear: they are not restricted in their choice of media technology equipment and are free from manufacturer-specific protocol considerations. The Beckhoff platform serves as a multi-language gateway, ensuring flexible communication among devices, as well as optimum usability.

Through the scalability and modularity of the software and hardware components from Beckhoff, users can tailor their control system precisely to the scope of the control tasks at hand. Users can achieve significant performance improvements and cost reductions, but also optimize available installation space. The CX2000 Embedded PC, for example, represents an extremely powerful and modular control solution based on multi-core processors from Intel®, helping to combine audio, PoE, DisplayPort and DVI on one universal platform.

Beckhoff technology highlights for AV and multimedia devices

The PC-based control principle

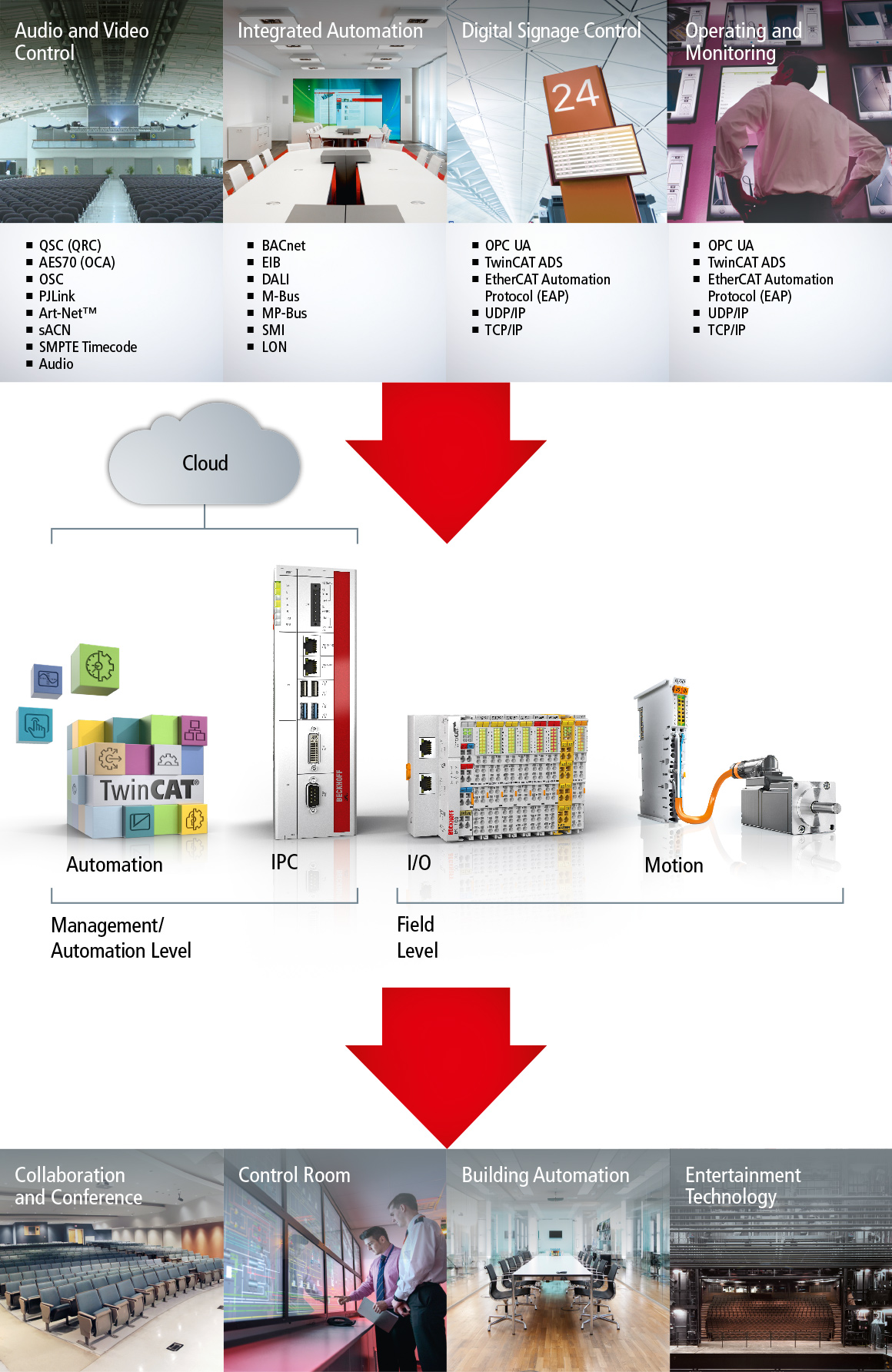

The PC-based control technology from Beckhoff has proven itself worldwide since 1980 in the widest variety of industries and applications, from the machine controller and the automation of wind turbines to building automation and AV and media technology. What was regarded 40 years ago as an outsider position developed very quickly into a standard in the automation industry. Innovative product developments that underlined Beckhoff's PC-based control philosophy followed continuously and are regarded today as milestones in automation technology, such as the modular Bus Terminal system, the high-speed EtherCAT fieldbus or the Embedded PC. The basis for the universal usability of the Beckhoff control solution is its modularity, its scalability in terms of power and its openness towards other systems and tools.

PC-based control from Beckhoff represents a modularly constructed control solution that is fully scalable in all components and maps all automation functions in software: safety technology, measurement technology, condition monitoring and robotics are also integrated into the control platform along with sequential control, motion control and visualization. The basic principle of PC-based control is very simple: it is based on a powerful Industrial PC, a high-performance fieldbus connection with the connected peripheral devices for sensors and actuators as well as TwinCAT, the real-time-capable automation software for cotion control and logic. The consistent use of mainstream technologies from the world of IT and their convergence to principles of automation technology have led to a continuous increase in performance and function as well as a considerable reduction in costs. The Beckhoff control platform is supplemented by an extensive portfolio of drive components.

With PC-based control, an extensive component construction kit is available to the system integrator for the automation of the various technical systems in the field of AV and media technology, such as audio and video control, building automation, digital signage control as well as operation and monitoring. Worldwide references from the areas of meeting and conference, control centers, building automation and entertainment technology prove that PC-based control technology is ideally suited for the implementation of technically demanding media productions.

Your advantage with PC-based control:

- High performance for the high-precision control of processes and applications:

- Industrial PCs with powerful processors of the latest generation

- TwinCAT, the software for engineering and real-time control

- EtherCAT, the high-speed fieldbus

- Consistency: one controller for all technical systems of a media application

- Openness: simple use of third-party software (audio players, C#, C++, graphic tools, etc.)

- Use of standard components, programming standards and networks

- Modularity: enables the extension and modification of controller functions at any time

- Scalability: components in all performance categories and designs

- Extensive connectivity: from the horizontal communication of the devices with one another to the cloud connection

- High availability: due to advanced diagnostics and predictive maintenance functions

- Beckhoff is a full system supplier with a deep understanding of technology

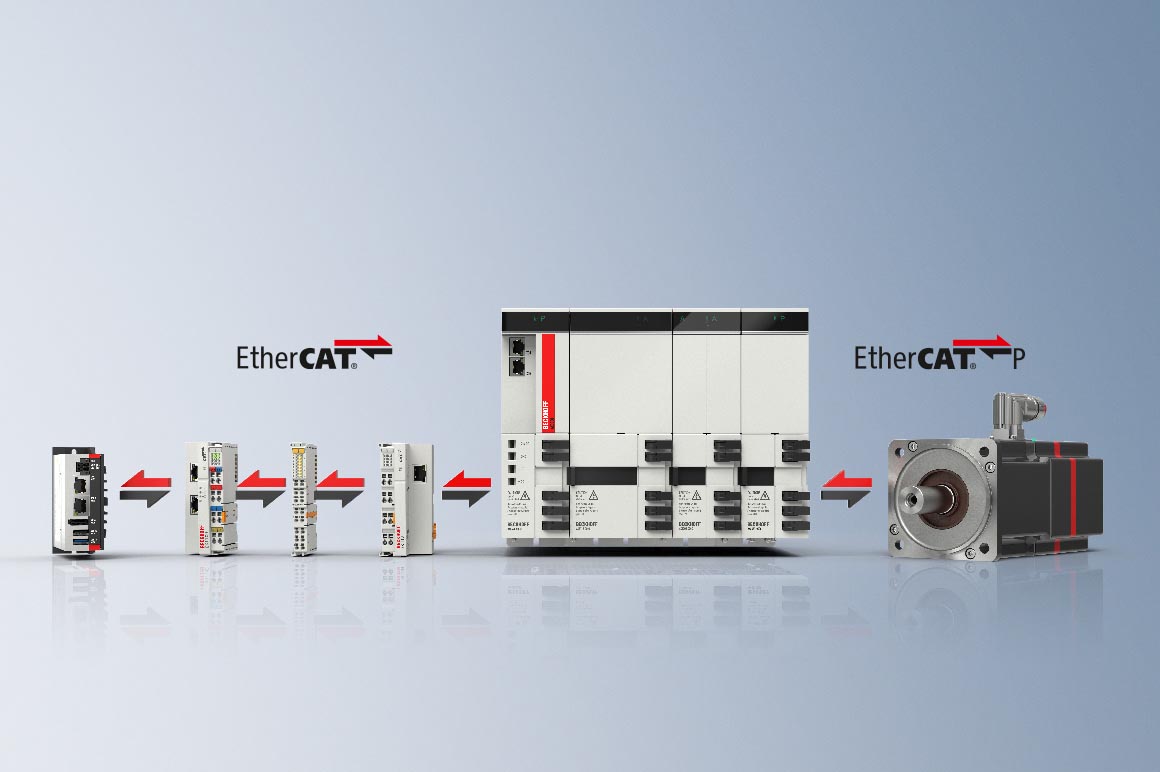

High-speed communication with EtherCAT

EtherCAT was launched by Beckhoff in 2003 and made available as an open automation technology standard. With cycle times well below 1 ms, outstanding synchronization accuracy, flexible topology selection, extensive diagnostics and simple configuration, EtherCAT is also ideal for use in AV and media technology. More than 6,000 companies worldwide have joined forces in the EtherCAT Technology Group (ETG), the world's largest industrial fieldbus user organization.

Beckhoff supplies the largest number of EtherCAT-compatible automation modules for both I/Os and drive technology. Due to worldwide support for EtherCAT, a large number of EtherCAT-compatible sensors and actuators are also available on the market, ensuring a high level of investment security. The performance of EtherCAT also supports creatives and engineers in the field of AV and media technology in the realization of unique applications. For example, a customer application such as "Kinetic Rain", a dynamic art installation in which 1,216 axes are synchronized, can only be realized on the basis of EtherCAT. With EtherCAT, almost any event in a show, museum, theater or amusement park can be synchronized, which is usually not possible with dedicated "black box" hardware, as it is normally used. The development of the DMX terminal, which requires 512 bytes of process data, is also based on EtherCAT; because as of today this is not possible with any other fieldbus system.

The general advantages of EtherCAT are:

- high speed

- simple diagnostics

- control of more than 65,000 devices

- EtherCAT allows the transmission of up to 64 kbit per slave

- perfect synchronization

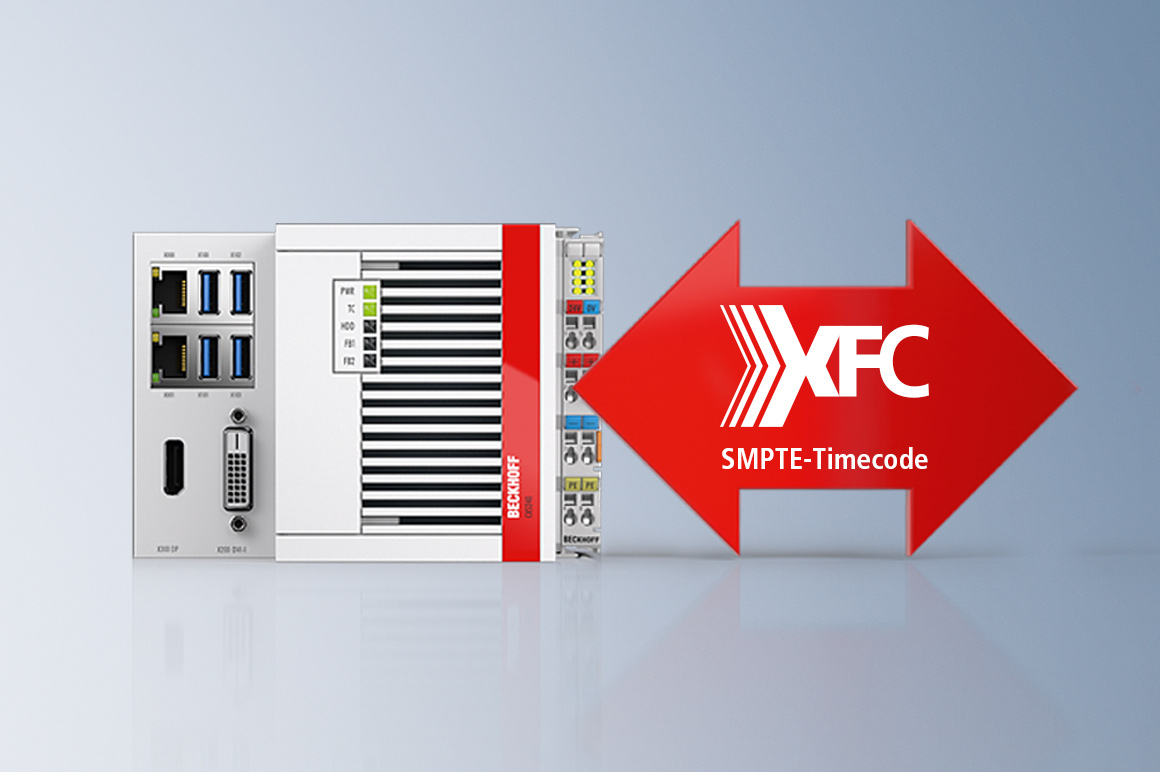

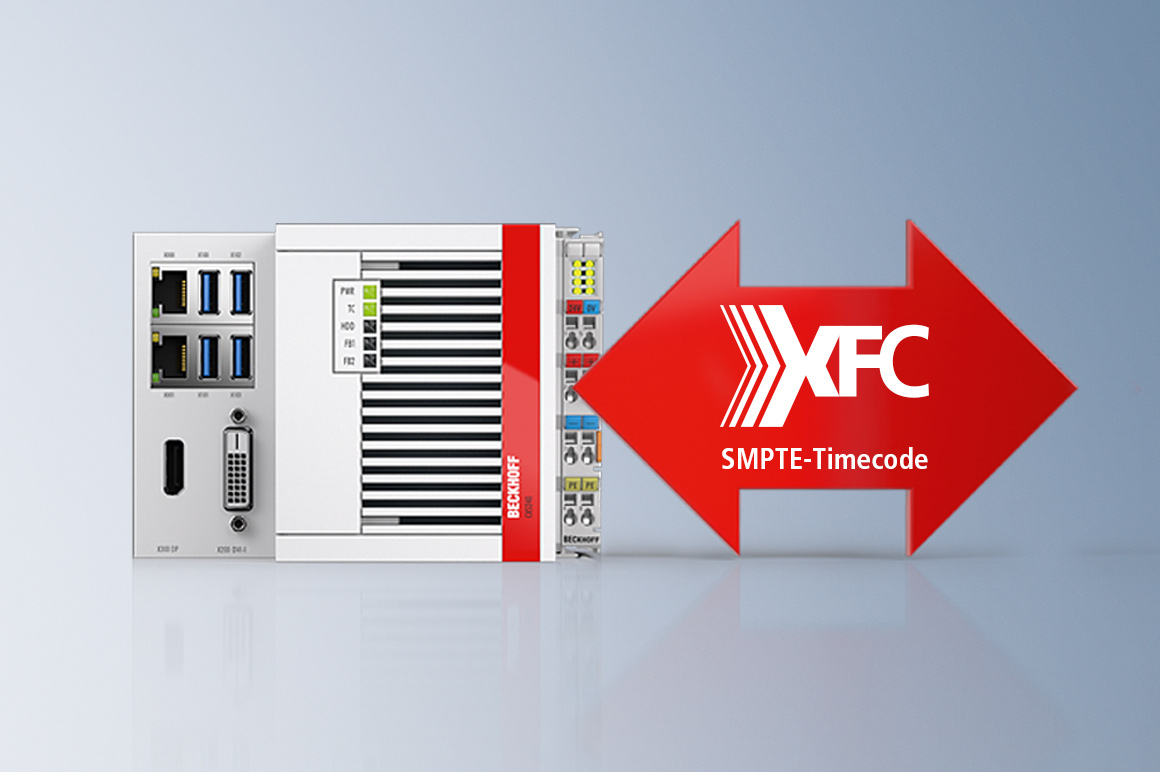

High-performance for AV and media technology supports SMPTE-Timecode

The XFC (eXtreme Fast Control) technology is an extremely fast control solution based on an optimized control and communication architecture. It consists of a modern Industrial PC, ultra-fast I/O terminals with advanced real-time features, the EtherCAT high-speed Ethernet system and TwinCAT automation software. With XFC it is possible to realize I/O response times < 100 µs. Due to its speed, XFC technology is used by almost all Beckhoff customers in the entertainment industry.

The development of this fast control technology was also a prerequisite for the support of the SMPTE-Timecode standard by the Beckhoff controller. The SMPTE-Timecode is a standard defined by the Society of Motion Picture and Television Engineers (SMPTE) for absolute time data that are transmitted with media metadata. The SMPTE-Timecode is mainly used to synchronize the various tracks (sound/noise, language, special effects, texts, etc.) in a media production.

EtherCAT I/O terminals automate any functionality in AV and media technology

In 1995, Beckhoff launched the Bus Terminal, which has since become one of the most important technology standards in automation technology. This was followed in 2003 by the development of the EtherCAT fast communication system. Launched by Beckhoff as an open system, it became a global standard in automation within a few years. With around 100 signal types, an extensive EtherCAT I/O Terminal portfolio is available to users that is extremely well suited for automating every functionality in media applications in terms of both its performance and variance. The Bus Terminals allow a variety of simple building bus systems to be integrated into the controller, for example: KNX/EIB, DALI, M-Bus and MP-Bus. This ensures compatibility and continuity with the existing system. Existing and future investments are protected.

In contrast to the Bus Terminals, in which the fieldbus signal is converted in the Bus Coupler to the internal, fieldbus-neutral terminal bus, the EtherCAT protocol is completely preserved up to the individual terminal with EtherCAT Terminals. The EtherCAT I/Os enable DMX and SMPTE-Timecode to be integrated into the controller. EtherCAT Terminals are used in almost every application of AV and media technology.

The universal basic function block for automation

The I/O signals are wired decentralized to fieldbus devices or centrally to the controller. The available vendor-specific fieldbus devices with fixed input/output configurations and design often make it necessary to use an entire group of devices with similar functions. This complex signal acquisition results in high material, installation, design and documentation expenditures as well as high costs for later changes or extensions. Inventory management and service staff are put under unnecessary strain.

The Beckhoff Bus Terminal is an open and fieldbus-neutral I/O system consisting of electronic terminal blocks. The head of an electronic terminal block is the Bus Coupler with the interface to the fieldbus. Bus Couplers are available for all leading fieldbus systems.

With the master terminals, fieldbus functionalities are also available in the form of a standard Bus Terminal. This is particularly advantageous for bus systems that are integrated as subsystems into a higher-level system. It means that only one system is required for the subsystem and for the higher-level bus interface. The master terminals are available for the following building bus systems: KNX/EIB, LON, DALI, MP-Bus, M-Bus.

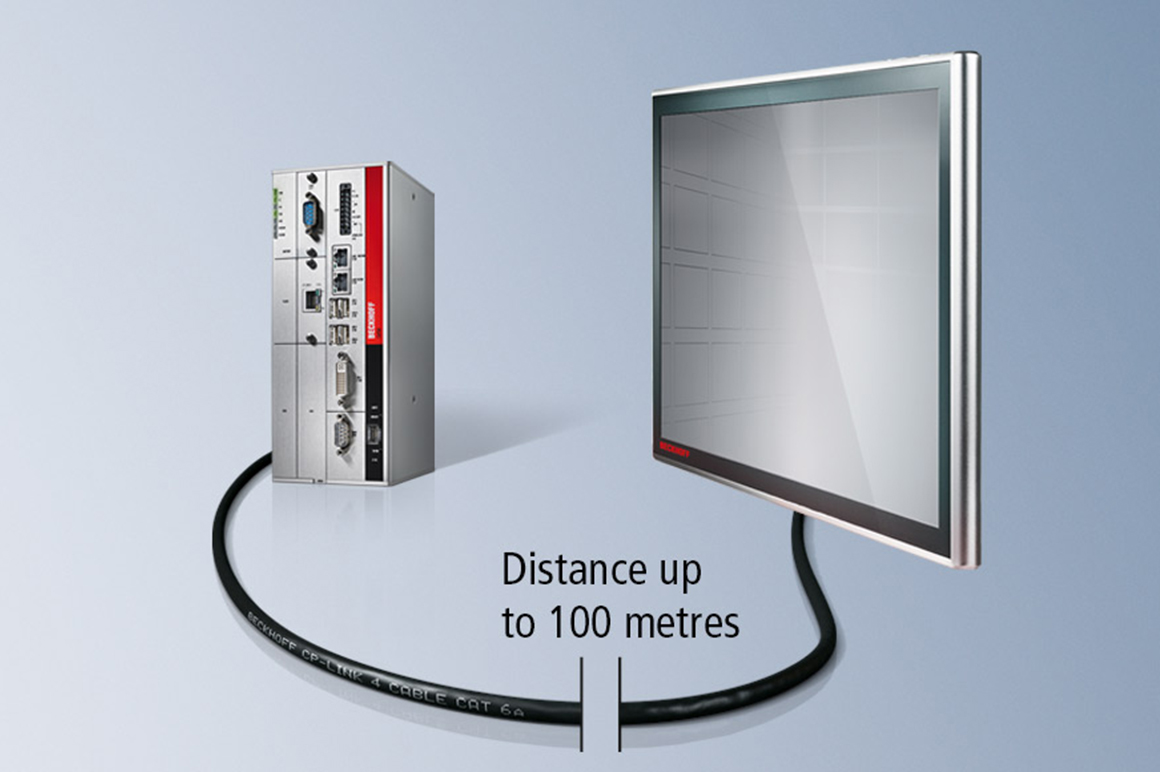

Simple panel connection in the field

CP-Link 4, the one cable solution for transmitting video signal, USB 2.0 and power supply via a commercially available Cat. 6A cable allows the Control Panel to operate up to 100 meters away from the PC. Cable and assembly costs are reduced with the one cable solution. A further benefit is the use of purely passive displays. The CP-Link-4 technology is supported by the Beckhoff multi-touch Panel series CP29xx-0010 (built-in variant) and CP39xx-0010 (mounting arm variant) and is interesting for many media applications.

Beckhoff product highlights for the control of AV and multimedia devices

AES70 OCA: the control protocol for professional audio devices

The AES70 standard was published by the Audio Engineering Society, which is based in New York. It defines a scalable control protocol for professional audio devices and describes monitoring and control of such devices, but not the transfer of media data. The function blocks of the TwinCAT 3 AES70 (OCA) Communication PLC library can be used to establish data exchange between a TwinCAT PLC and an (audio) device that supports the AES70 (OCA) standard. The user can query or set properties of different objects in a device (OCA device). Function blocks such as Gain, Mute and Switch are available for this purpose. They implement any OCA structure and map any OCA device. Beckhoff offers prefabricated function blocks for devices from d&b audiotechnik.

With TF8810, OCA-capable audio systems can be integrated into Beckhoff's PC-based control platform and combined with components from the wide range of Control Panels and I/Os. TF8810 includes a license for TF6310.

TCP/IP Server

TwinCAT TCP/IP TF6310 is used to implement and realize one or more TCP/IP servers and/or TCP/IP clients in the TwinCAT 3 PLC. Corresponding function blocks exist for the establishment/disconnection of communication as well as for the pure exchange of data (send and receive). The function blocks also support the use of multicast addresses here. Many of the communication interfaces in AV and media technology are based on TCP/IP, which is why TF6310 is used in almost all multimedia projects with Beckhoff control technology. TF6310 is the basis for the support of sACN, Art-Net, PosiStageNet, QSC and PJLink.

PJLInk enables the configuration of video projectors via a network interface

PJLink is a standard that is not limited to one projector manufacturer or to one specific projector model. PJLink thus enables central control of projectors from different manufacturers. It contains basic commands and status queries that are important for control and monitoring.

QRC protocol for the system integration of audio and video devices

QSC is a professional provider of audio/video system solutions. Its software-based platform is called Q-SYS. Q-SYS offers third-party systems the control and monitoring of various aspects of the system with the help of various communication protocols. Beckhoff supports the most up-to-date and extensive way of integrating Q-SYS devices with a code example to QRC. Details of the connection can be found in the following section:

The Q-SYS software supports the following types of external controllers:

- Named Controls - controls that have been stored in the Named Controls area. The names of the controllers must be different. [This is part of the control level of Q-SYS.]

- Component Control - control of all controllers within a component by adapting the component's name so that it is unique. [This is part of the component level of Q-SYS.]

- Mixer Control - specialized control of mixers with the help of mixer concepts. [This is part of the component level of Q-SYS.]

Basically, there are two different protocols provided by QSC for accessing the three external controllers for Q-SYS mentioned above. These are called "Q-SYS External Control Protocol" and "Q-SYS Remote Control" (referred to below as QRC)

- The Q-SYS External Control Protocol is based on ASCII and uses a TCP/IP connection on port 1702. It requires the use of Named Controls for each controller that is to be controlled externally. This means that it only supports the functions of the control level of Q-SYS.

- QRC is the latest and most advanced protocol from QSC that allows an external control system (e.g., TwinCAT) to control various functions in Q-SYS. The QRC protocol is based on JSON-RPC version 2.0 and uses a TCP/IP connection on port 1710. QRC supports the use of all three of the controllers mentioned above: Named Controls, Component Control and Mixer Control. On this basis, it allows external access at the control level and component level. Beckhoff supports QRC with a code sample.

Open Sound Control (OSC) for real-time processing of sound

MIDI applications can communicate with Ethernet over TCP/IP using Open Sound Control (OSC). The basis of the integration of MIDI into the Beckhoff controller is the TF6310 TwinCAT TCP/IP server module, which allows the implementation of one or more TCP/IP servers or clients.

sACN for network transmission of DMX data

DMX is a standard that is widely used for controlling lighting elements in stage equipment and building services applications. Beckhoff offers the EL6851 DMX master terminal and the EL6851-0010 DMX slave terminal for this purpose.

To take advantage of Ethernet for DMX, the Entertainment Services and Technology Association (ESTA) has developed the Streaming Architecture for Control Networks (sACN). This transmits the data of the DMX universe via UDP/IP. The DMX data is embedded as a complete universe in the sACN frame and thus tunneled through UDP/IP. sACN is defined by the ANSI standard E1.31-2009 (sACN-2009 for short) and represents a subset of the ACN standard (ANSI standard E1.17).

In 2016, the ESTA introduced the new edition of the sACN standard E1.31-2016 (sACN-2016 for short), which added two new frame types, the "Synchronization Frame" and the "Universe Discovery Frame". The Synchronization Frame is a packet that contains only synchronization information from the universe and is used to trigger the synchronization. The Universe Discovery Frame is a packet that contains a packed list of the universe in which a source is active. This frame allows other devices interested in network traffic to monitor which universes are currently active without having to join every multicast group. Beckhoff supports the variants E1.31-2009 (sACN-2009 for short) and E1.31-2016 (sACN-2016 for short) with sample code.

Art-Net™ for the transfer of DMX universes via UDP

Art-Net™ is a protocol specification, developed by Artistic License Holdings Ltd, to utilize the benefits of Ethernet for transferring DMX universes. DMX is a standard that is widely used for controlling lighting elements in stage equipment and building services applications. The corresponding Beckhoff range includes the EL6851 DMX master terminal and the EL6851-0010 DMX slave terminal. Art-Net is very similar to sACN.

Art-Net™ transfers DMX universes via UDP/IP, whereby DMX data are embedded in an Art-Net™ frame as a complete universe and thus tunneled through UDP/IP using another layer. From Art-Net™ II, telegrams can also be sent in "unicast" mode, as well as "directed broadcast".

Beckhoff offers a sample code for Art-Net II.

PosiStageNet for the transmission of position data

PosiStageNet (PSN) is a protocol specification for the transmission of position data and was developed in collaboration between VYV and MA Lighting. PSN is mainly used in stage and entertainment technology. The data are transmitted by UDP/IP.

In general PSN is used to transmit the position data of objects, these objects being called "trackers". The method of determining the position data is not specified and is left up to the user. For example, position data from a position measuring system (encoder) can be used; these are then sent to a lighting controller for the automatic "tracking" of this object.

Further communication protocols for media technology that can be used on a Beckhoff controller are: DMX, SMPTE-Timecode, DALI, KNX/EIB, SMI, MP-Bus, M-Bus and EnOcean.

SMPTE-Timecode synchronizes video and audio devices

The SMPTE-Timecode is a standard defined by the Society of Motion Picture and Television Engineers (SMPTE) for absolute time data that are transmitted with media metadata. The SMPTE-Timecode is mainly used to synchronize the various tracks (sound/noise, language, special effects, texts, etc.).

With the help of the EL3702 EtherCAT oversampling terminal, the analog signal sent from the master to the slaves can be "intercepted" and used via TwinCAT for the synchronization of different subsections and systems.

Extremely space-saving, flexibly expandable and sturdy: the new generation of ultra-compact Industrial PCs

Launched with the C6015, the series of ultra-compact Industrial PCs has positioned itself extremely successfully on the market due to its flexible application possibilities. As a sturdy Control cabinet Industrial PC with an Intel® Atom™ CPU with up to four cores and a clock speed of 1.91 GHz, the C6015 is suitable for automation, visualization and communication tasks. The small dimensions of 82 x 82 x 40 mm and the flexible mounting options make the fanless multi-core PC the ideal controller for applications with high performance requirements and minimal mounting space in almost all areas of AV and media technology. The interfaces for transferring electrical signals, IP, image and audio signals, which are available by default, make the C6015 suitable for cost efficient control of media walls, for example.

The C6017 multi-core computer, which measures just 82 x 82 x 66 mm, adds a variant to the family with additional optional interfaces. Due to its high computing power and fanless design, the C6025 is particularly suitable for demanding control applications that also take into account the aspect of green IT. The basis for this is the Intel® Core™ i U processor, which consumes significantly less power. The C6030 offers advantages such as low space requirements, universal usability and flexible mounting, even for complex applications with the highest performance requirements. The C6032 has a further board level for modular interface and function extensions. The use of compact PCIe modules allows it to be perfectly adapted to the respective multimedia application and requirement profile.

Powerful, reliable and flexibly expandable: the Embedded PC series for control tasks in AV and media technology

The compact DIN-rail PCs from the CX series with directly connectable I/O level offer a space-saving industrial controller in the control cabinet. Beckhoff's extensive range of embedded controllers includes a device tailored to the budget, performance class and complexity of the control task for each application. In addition to the CPU, the individual devices from the CX series differ by the available system interfaces and power supply variants and can be plugged together and extended as a modular control system depending on the task in the field of AV and media control.

The CX family includes several basic CPU modules with different processors for adaption of the performance to suit the respective control task. As a result, different applications can be implemented on the same hardware, such as a PLC and motion control system with a DVI/USB interface or a multimedia system with an audio interface. The most powerful devices from the CX series are the CX20x2s, which are equipped with Intel® Xeon® processors and a separate graphic unit. They can be used to realize even sophisticated visualizations.

Optimized graphics functionality with the DisplayPort

The DisplayPort transfers image and audio signal at the same time and is therefore suitable for connecting panels or monitors to the Embedded PC. The CX5130, CX5140 and CX20x0 Embedded PC devices are available with a DisplayPort and allow the connection of a monitor with a resolution of up to 2560 x 1600 at 60 Hz. A second monitor can be controlled via the DVI interface. This enables use in a variety of media applications.

Maximum flexibility for proven and new operating concepts with multi-touch

The Beckhoff Panel generation with industry-standard multi-touch displays offers the right solution for any application. The wide variety of versions ranges from different display sizes and formats to customer-specific executions and can thus be used in many media applications. For single-touch users, the new panel generation also offers excellent value for money and a smart alternative to other systems.

Highlights

- display sizes from 7-inch to 24-inch (16:9, 5:4, 4:3)

- landscape and portrait mode

- multi-touch (PCT): e.g., for 5-finger or 2-hand touch operation

- high touch-point density for safe operation

- high-quality aluminum housing, milled from a solid block

- metal perimeter protection for the display front

- built-in or mounting arm models

- Control Panel with CP-Link 4 or DVI/USB-Extended technology

- Panel PCs with CPUs from Intel® Atom™ to Core™ i7

- optional electromechanical push-button extension

Open, PC-based control technology

TwinCAT automation software integrates real-time control with PLC, NC and CNC functions in a single package. All Beckhoff controllers are programmed using TwinCAT in accordance with the IEC 61131-3 programming standard. In addition to IEC 61131-3, TwinCAT 3 also offers C/C++ and MATLAB®/Simulink® as programming languages.

TwinCAT 3 Highlights

- only one software for programming and configuration

- Visual Studio® integration

- more freedom in the choice of programming language

- support for the object-oriented extension of IEC 61131-3

- use of C/C++ as a programming language for real-time applications

- link to MATLAB®/Simulink®

- open interfaces for expandability and adaptation to existing tool landscape

- flexible runtime environment

- active support for multi-core and 64-bit operating systems

- migration of TwinCAT 2 projects

- automatic code generation and project creation with the TwinCAT Automation Interface

Integration in Microsoft Visual Studio® makes it possible to program automation objects in parallel with the aid of the 3rd edition of IEC 61131-3 and the C or C++ languages. The objects generated (modules) can exchange data with each other and call each other independently of the language they were written in. The TwinCAT System Manager has been integrated into the development environment. Hence, only one software is required to configure, parameterize, program and, if necessary, to diagnose automation devices.

The quicker way to the individual user interface

TwinCAT HMI consistently relies on widely used IT standards such as HTML5, JavaScript and CSS. The integration of a full graphic editor with an extensive toolbox into the familiar TwinCAT engineering environment makes it possible to create extensive visualization pages for multimedia applications with little effort. Customer-specific functions that are not part of the visualization toolbox can be implemented via the above-mentioned IT standards or higher-level programming languages. The visualizations created are independent of the client's platform and responsive. The powerful basic architecture makes numerous application scenarios possible in the field of media technology: from the local panel solution to multi-client, multi-server and multi-runtime concepts for digital signage applications, user interfaces for media applications, room control units or other HMI.

Beckhoff relies on proven IT standards:

- Visual Studio® for the engineering

- HTML5 for the design

- TLS for secure communication

- execution of the user interface on any HTML-capable browser, regardless of operating system, resolution and display