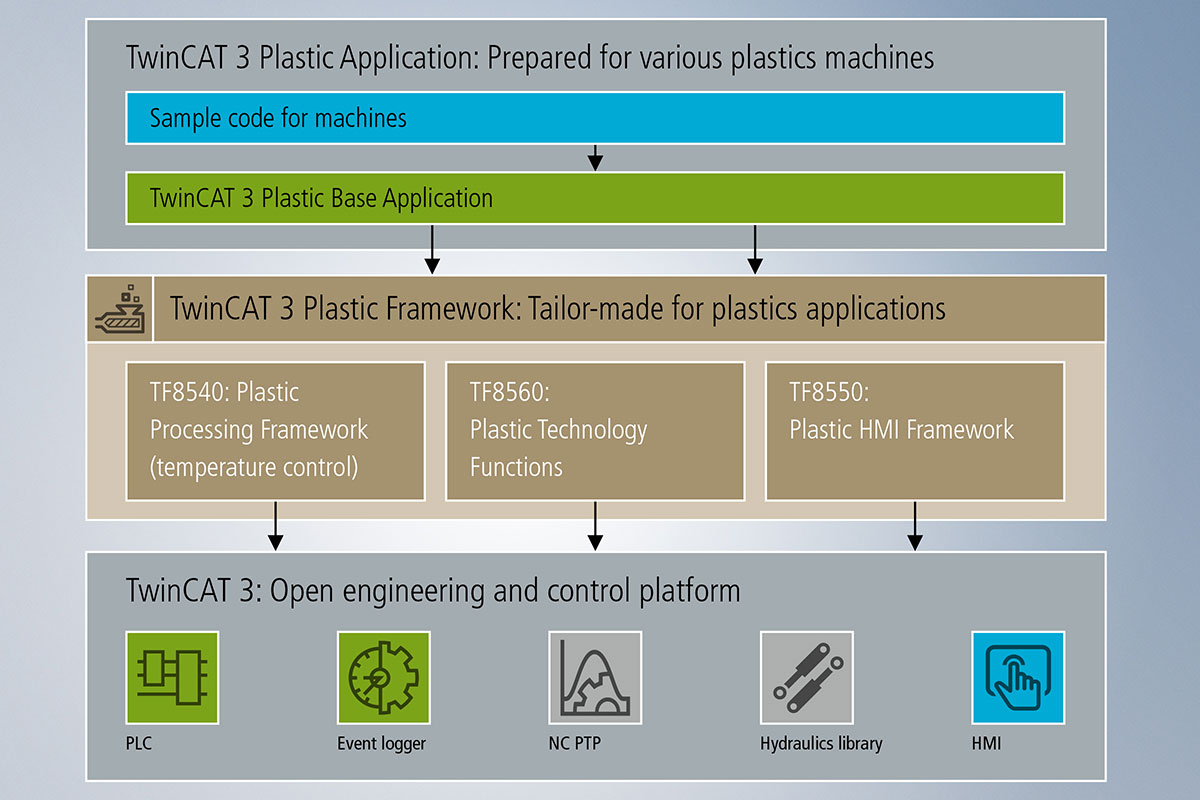

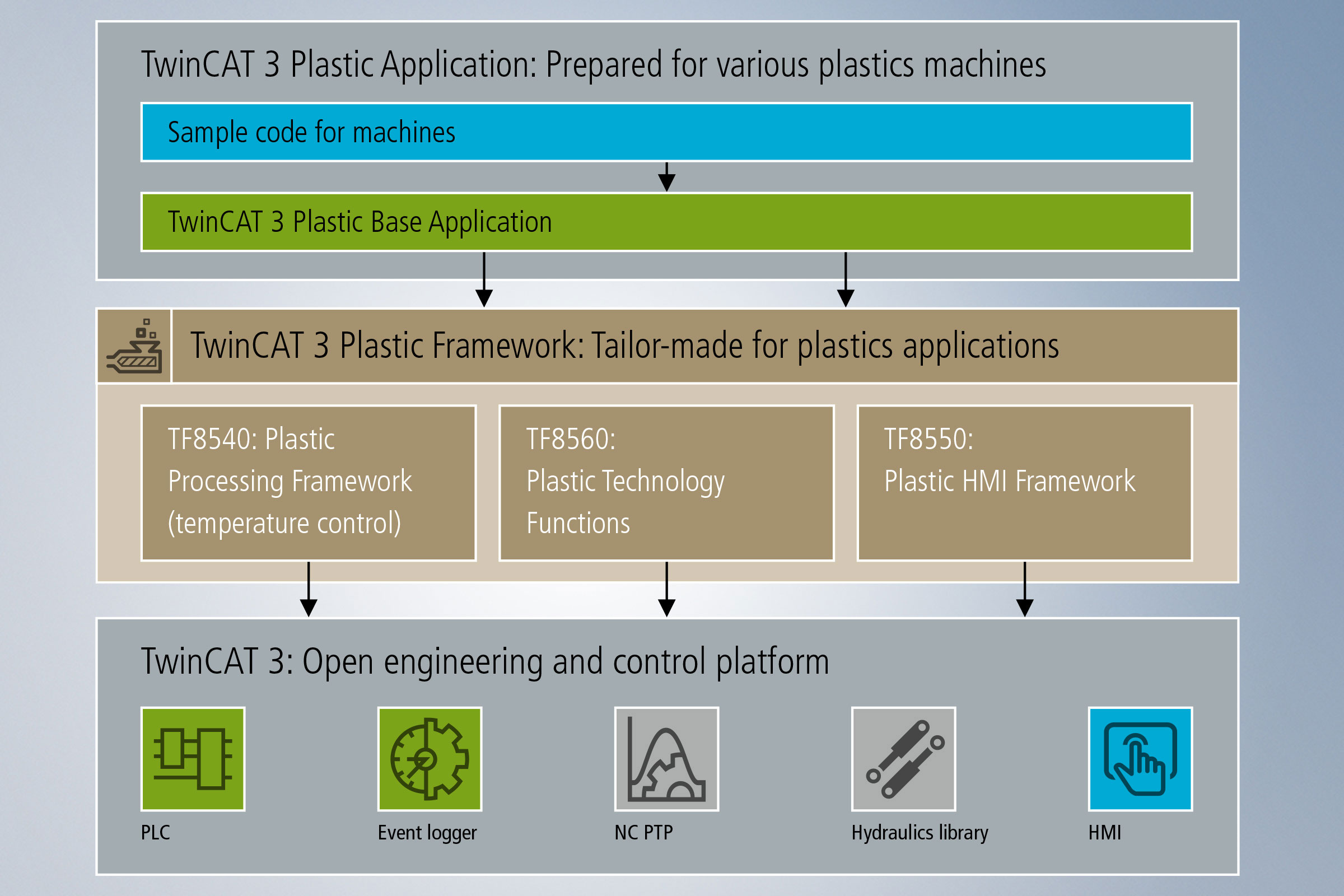

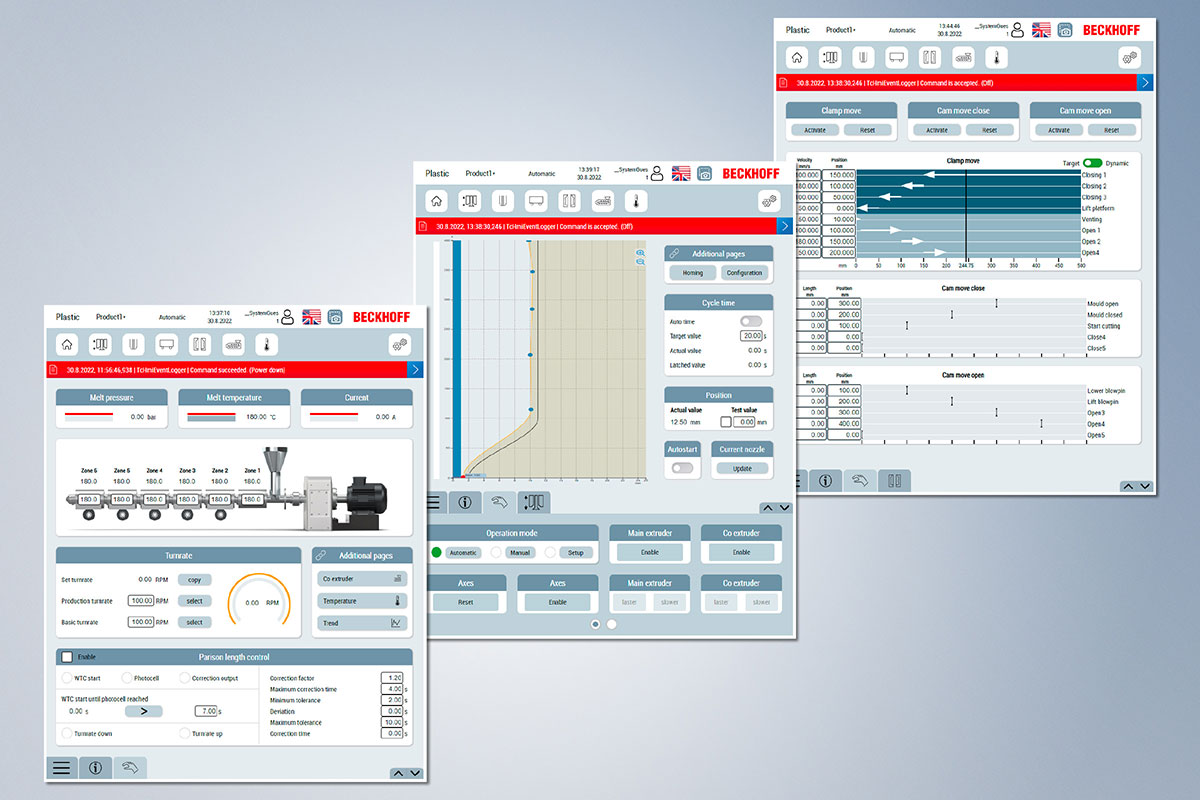

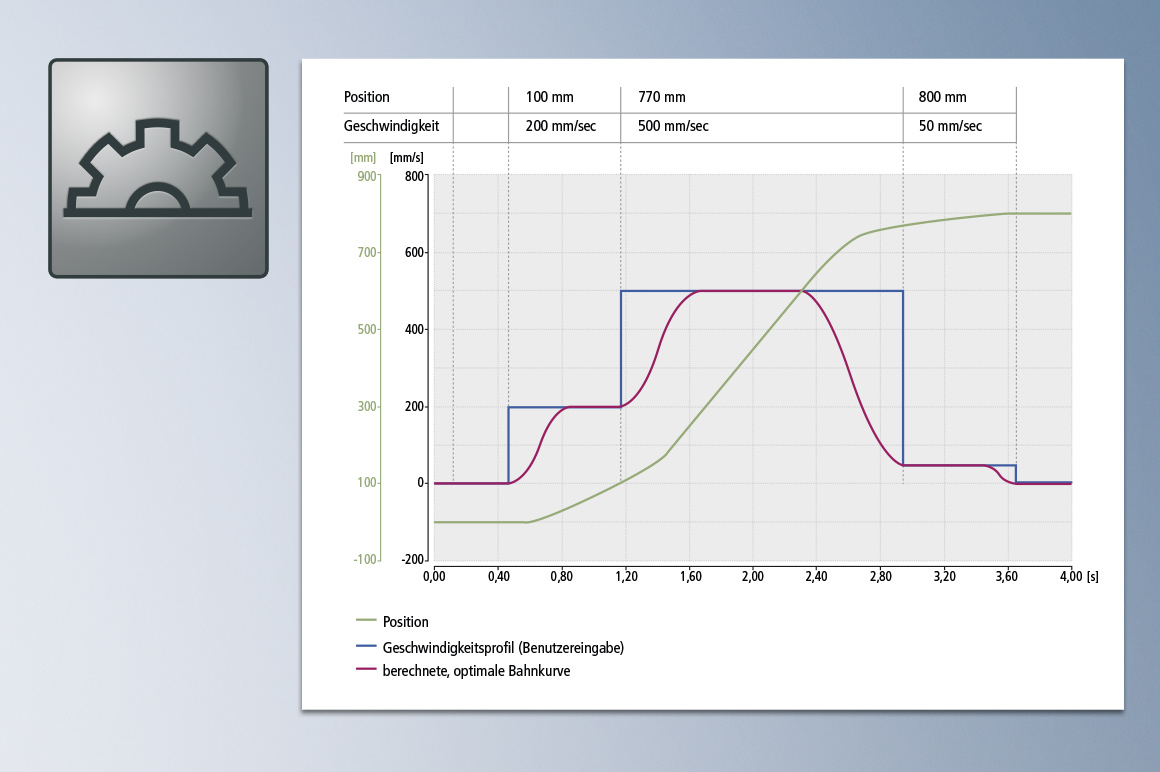

Beckhoff has been a partner of leading companies in extrusion blow molding technology for many years. Hardware and software components from Beckhoff are used by a global customer base. From individual components to the complete solution, the user benefits from Beckhoff's broad process and application know-how in blow-molding technology. Beckhoff's extensive know-how in hydraulic drive technology, for example, leads to the best results with axes that are demanding in terms of control, such as transport movement, even with cost-reduced hydraulics. Modern servo-electric concepts are modularly integrated into the software architecture: machine programs for hydraulic, electric or mixed drive technology are created and maintained in an identical development environment. The core component of blow molding machines, parison control, is carried out with high precision in the entire range of different machine concepts.

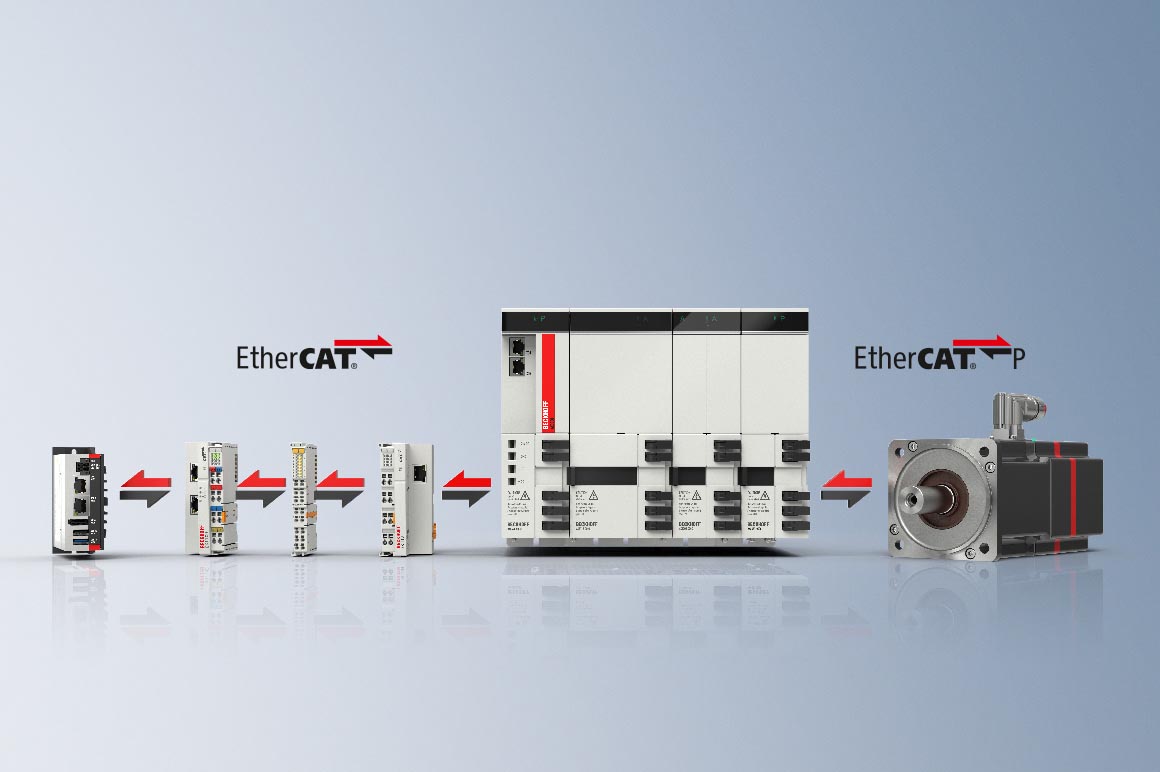

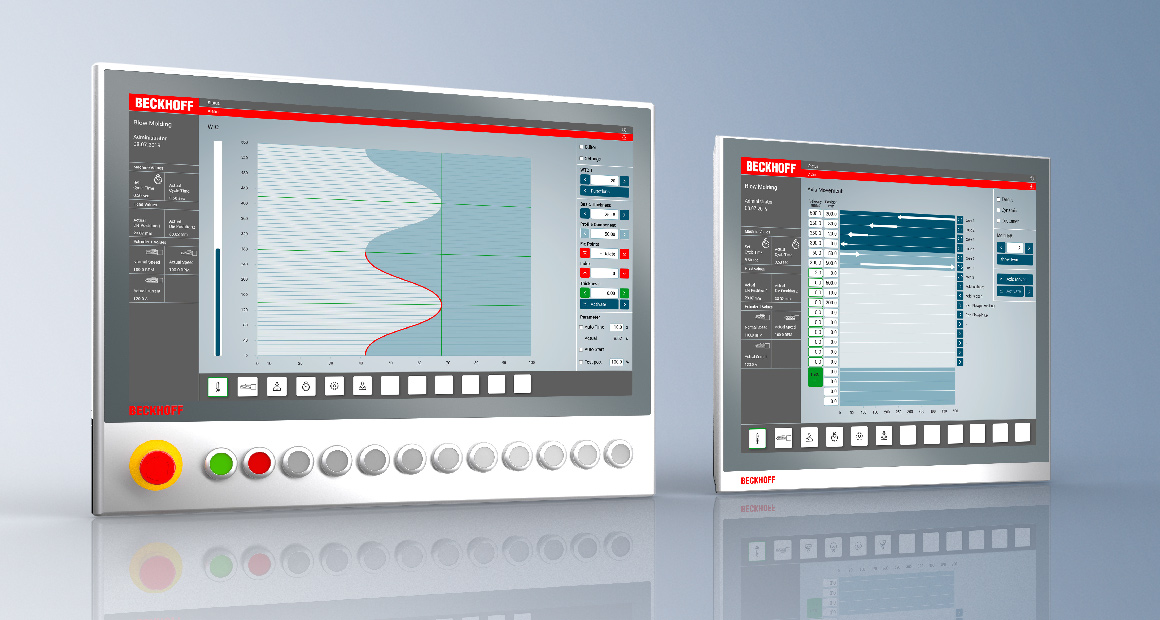

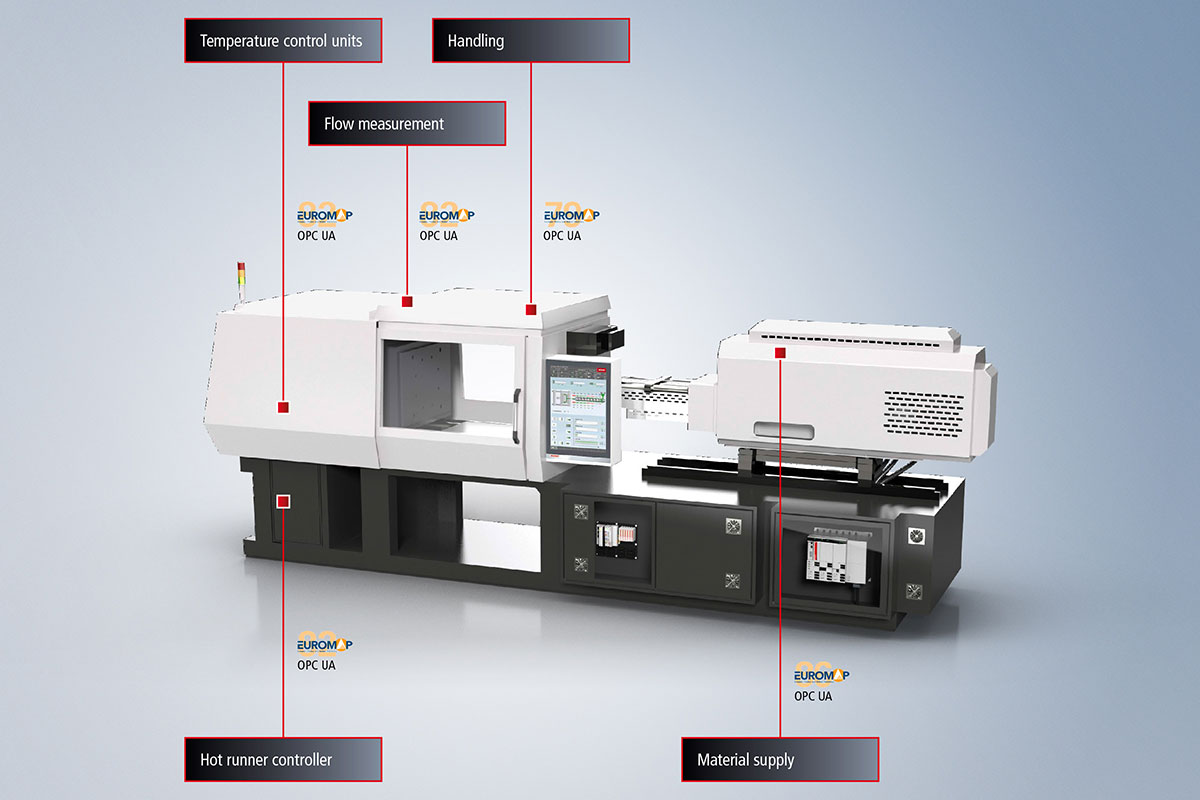

The trend towards complete production cells is supported by the extensive Beckhoff hardware and software portfolio. As if from a construction kit, machine manufacturers can assemble a suitable control solution for their system or plant type. The automation toolkit comprises an extensive portfolio of Industrial PCs as well as control and display devices in all performance categories and form factors. EtherCAT, the global standard for real-time communication, offers maximum performance in integrating third-party power controllers. The Beckhoff I/O system covers a wide range of sensors and actuators and supports interfaces to different fieldbus systems. In TwinSAFE, Beckhoff has developed an integrated safety solution that reduces the engineering effort, especially for production cells, due to its flexibility. Servomotors and drives of all performance classes are available for the axis movement of electrically driven machines.