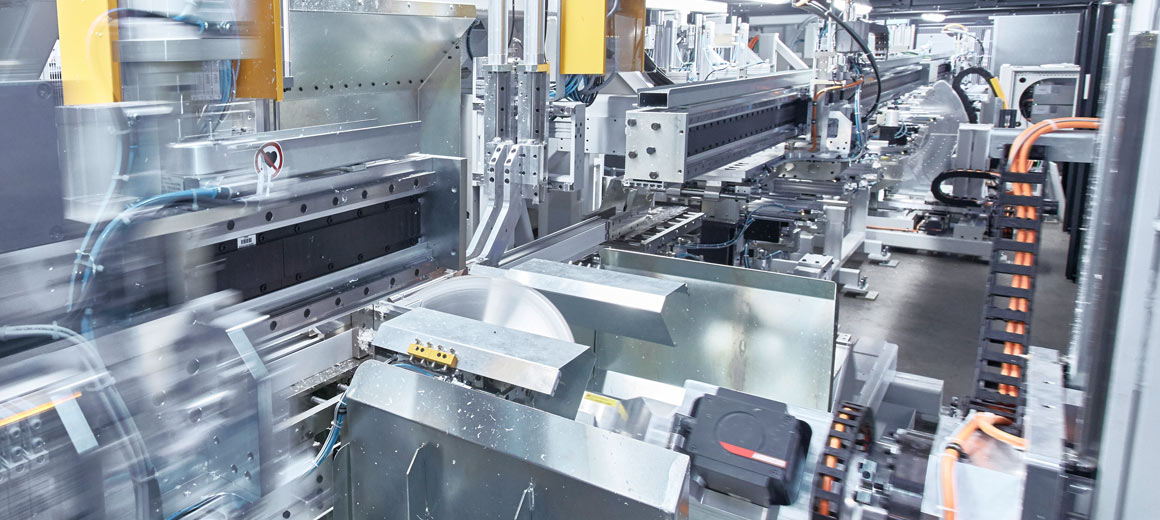

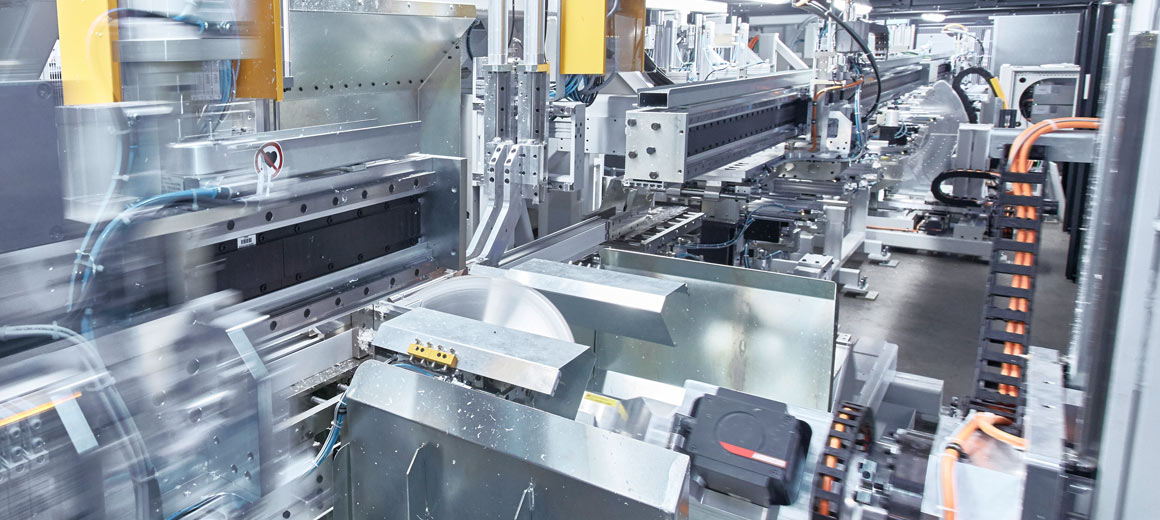

Machines must expand beyond their basic functions by providing optimal production capability in the long term, continuously supplying information on energy and resource consumption, as well as being easy to integrate into existing information structures. Only then can digital business models, e.g., for predictive maintenance or usage-based billing, be implemented effectively. All this is possible with the machine-integrated measurement technology from the Beckhoff I/O system:

The benefits of control-integrated measurement technology in machine building:

- Fast measurement technology modules with high measurement accuracy ensure synchronous signal acquisition and full data access, allowing more precise process control with tighter tolerances.

- Direct integration and signal analysis with PLC libraries in the control system cuts down on external computers, data loggers, and extra synchronization and connectivity work.

- All process information and measuring signals are available in the control system for full condition monitoring at any time.

- From standard terminals to highly precise measurement technology modules, you can find the right product for every measurement task – including transparent energy and status information.

- Product- or batch-related energy data can be calculated in the control system and stored in production databases.

- PC-based control provides comprehensive connectivity by supporting all fieldbuses, OPC UA, and IoT technology.

- Energy measurement values of varying complexity can be recorded in an integrated system.

You can find more information about our technology and products for system-integrated measurement technology in machine building here: