Industrie 4.0-compliant truck and bus tire plant

Continental Reifen Deutschland GmbH, Germany

Representative office Philippines

Continental Reifen Deutschland GmbH, Germany

Beckhoff provides machine builders and end customers in the tire and rubber industry with a high-performance and maximally scalable system solution that can be used throughout the entire production process: from material preparation and tire construction, through curing, conveyor technology, and material handling, right up to final inspection. TwinCAT automation software and powerful industrial PCs, together with high-performance motion control and EtherCAT-based I/Os, form the basis for the precise synchronization of all processes – including system-integrated test bench automation, vertical integration and MES integration via Industry 4.0 standards such as OPC UA.

Do you have any questions?

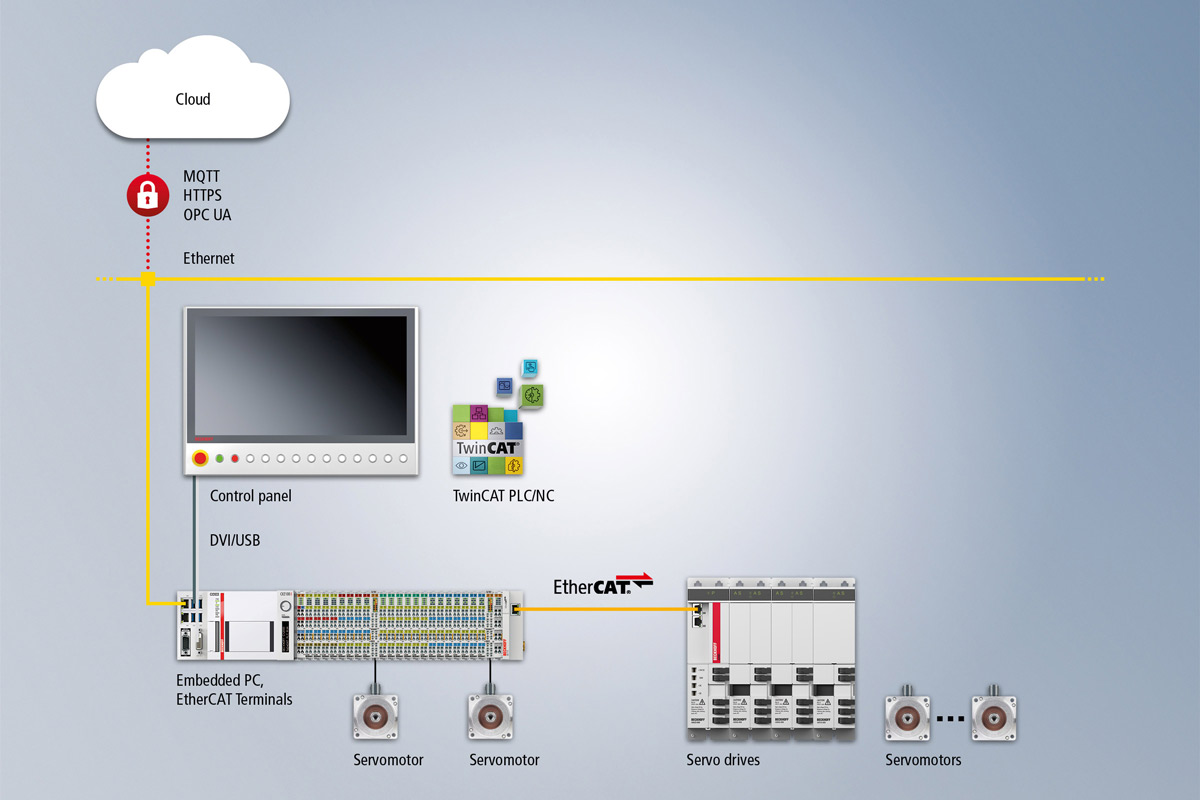

Together with the TwinCAT NC PTP software, powerful industrial PCs and control panels form the control platform for the motion control system. Standard functions such as cam plates and the flying saw are available in TwinCAT especially for use in the preparation and assembly sector. Integrating condition monitoring and vision in TwinCAT means that external solutions for monitoring and image processing are no longer required.

Servo drive technology not only supports electronic motor rating plates for plug-and-play, but also safety technology. Drive parameterization and parameter storage are completely integrated in TwinCAT. The servomotors are connected cost-effectively via One Cable Technology, which combines power and feedback signals in a single standard motor cable. For adjustable axes with absolute encoders, the servomotor terminals offer a compact solution for the I/O system.

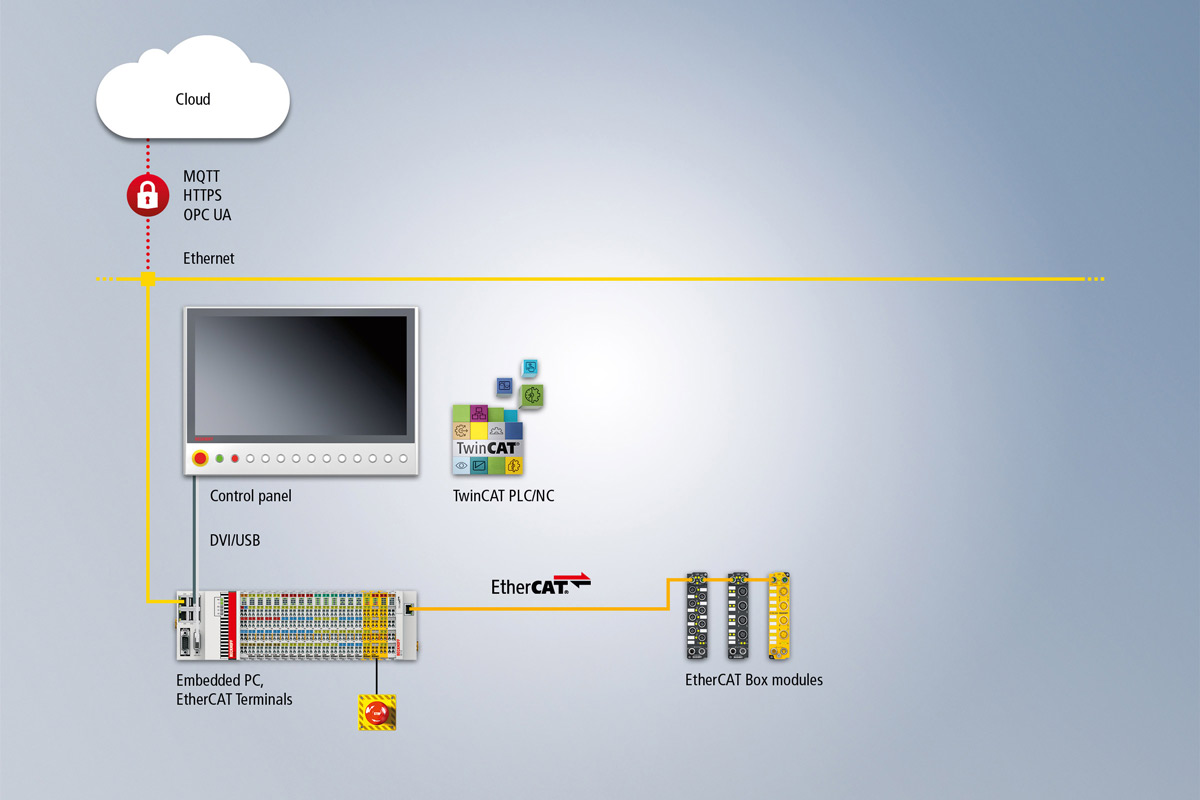

Robust control panels and compact embedded PCs form the basis of the PC-based control system for curing. The fast EtherCAT fieldbus and the EtherCAT Box modules with an IP67 protection rating for standard and safety signals, the EtherCAT Terminals for an extended temperature range, and high-precision, calibrated temperature detection terminals constitute the ideal fieldbus platform for heating press control.

The basic software for hydraulic and mechanical curing presses and the TwinCAT Controller Toolbox help manufacturers bring products onto the market fast. The production data can be archived using built-in mass storage, standardized cloud protocols, and direct database connection from the PLC.

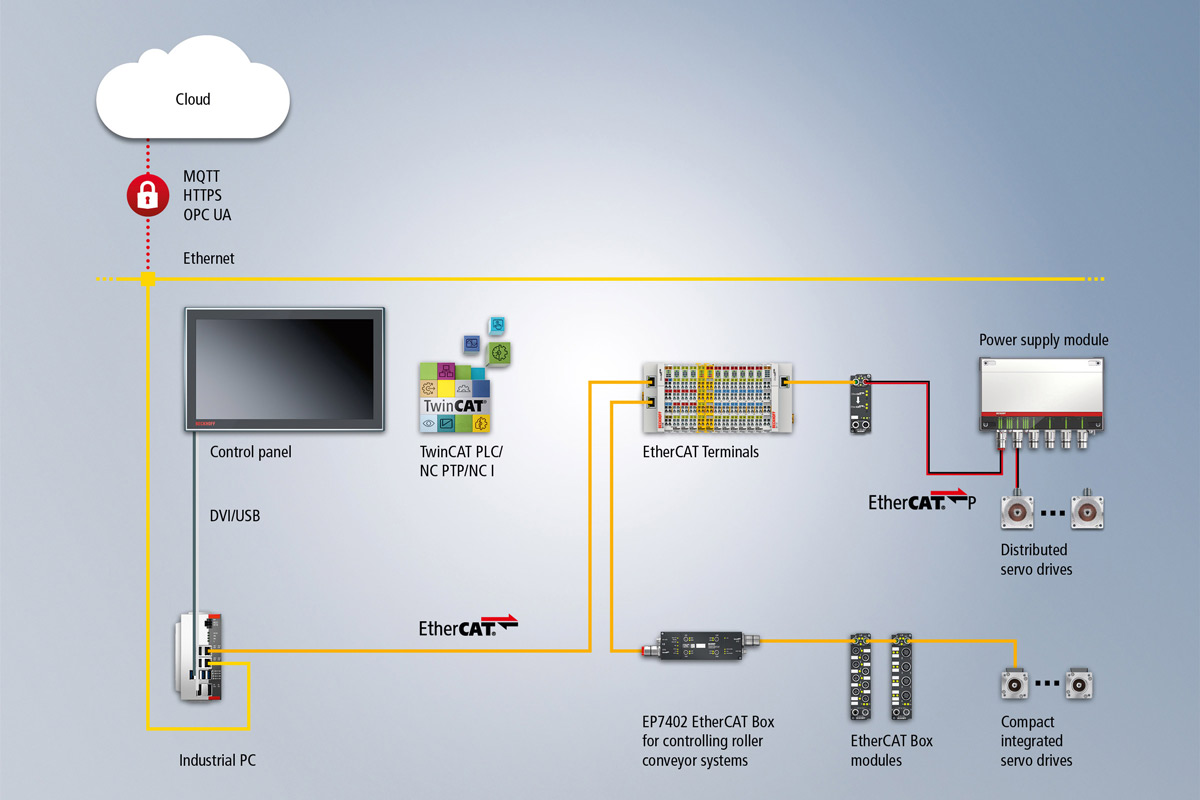

PC-based control with distributed EtherCAT I/O Terminals and EtherCAT Box modules from the EP/EPP series is ideally suited for use in conveyor systems for transporting tires from the machine to other processing stations. The EP7402 EtherCAT Box can be used to control roller conveyor systems. EtherCAT enables large systems with distances of up to 100 m between the individual I/O islands to be put into operation. The cable redundancy offered by EtherCAT ensures high system availability.

Distributed drive concepts, such as those commonly found in conveyer systems, can easily be integrated into the central control system, thanks to the multi-fieldbus capability of the Beckhoff automation platform. Different hardware components such as scanners, RFID units, camera systems for product tracking, or even robotic systems are controlled via gateways and interfaces. The distributed TwinSAFE safety system replaces the wire-based safety chain. The TwinSafe components read the safe signals from the system. The data transfer to the PC is performed via the Safety over EtherCAT protocol.

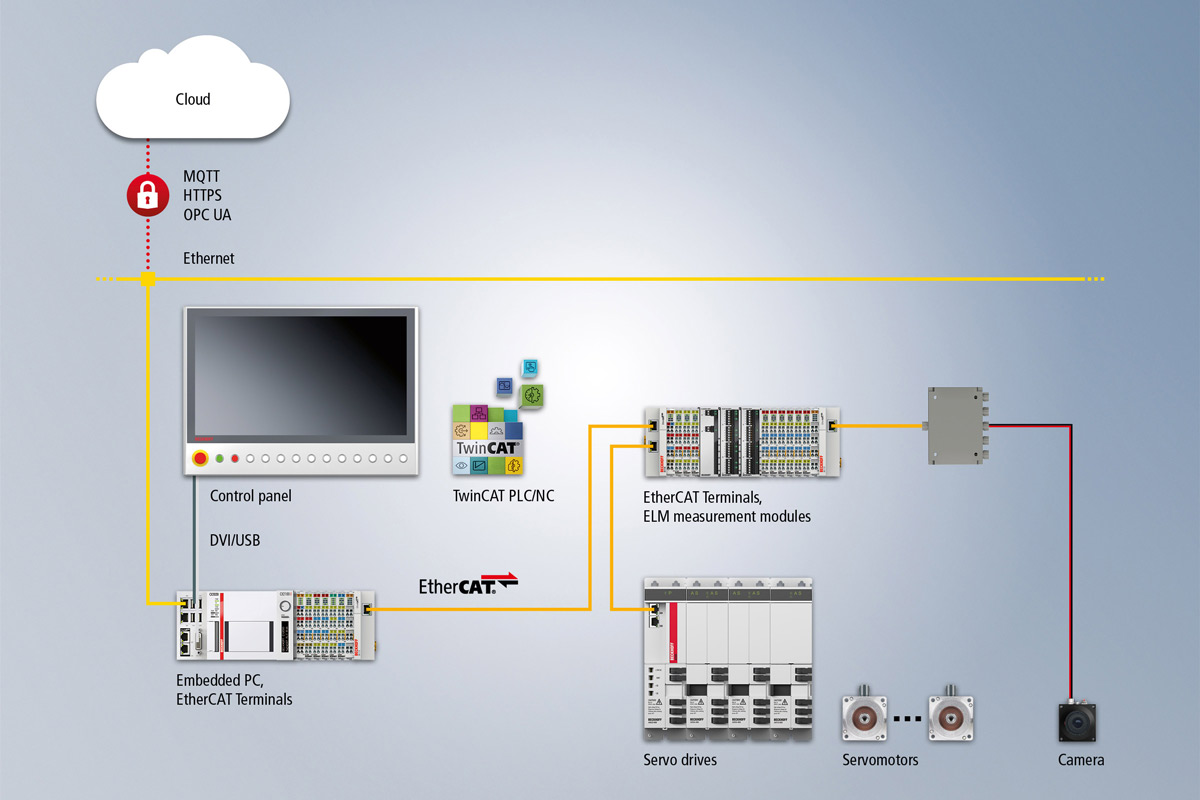

PC-based control with integrated measurement technology is the optimal base for test and inspection machines in tire production. High-performance industrial PCs, control panels with touch screen and mechanical push-button fields, EtherCAT I/Os with gateways to subordinate fieldbus systems, along with TwinCAT for controlling machine processes and motion control constitute the components of a lean, highly integrated control architecture.

Sequence control and measurement tasks are carried out with PC-based control on an integrated platform. The fast and highly accurate ELM series measurement modules are used for demanding measurement tasks. The integration of the measurement technology into the control system offers the advantage of synchronous signal acquisition and full data access, which means that the whole range of process data and measurement signals are available to the control system at any time. In addition, a vision portfolio containing hardware and software is available for optical inspection. The integration of C/C++ and MATLAB® and Simulink® into the TwinCAT automation software opens up a wide range of applications in test and inspection machines for final inspection.