Products

AF1000 | Economy variable frequency drive

The variable frequency drives in the AF1000 series are particularly suitable for performing basic drive tasks cost-effectively.

Software

The motion software products optimally support the selection and commissioning of suitable hardware components for drive solutions.

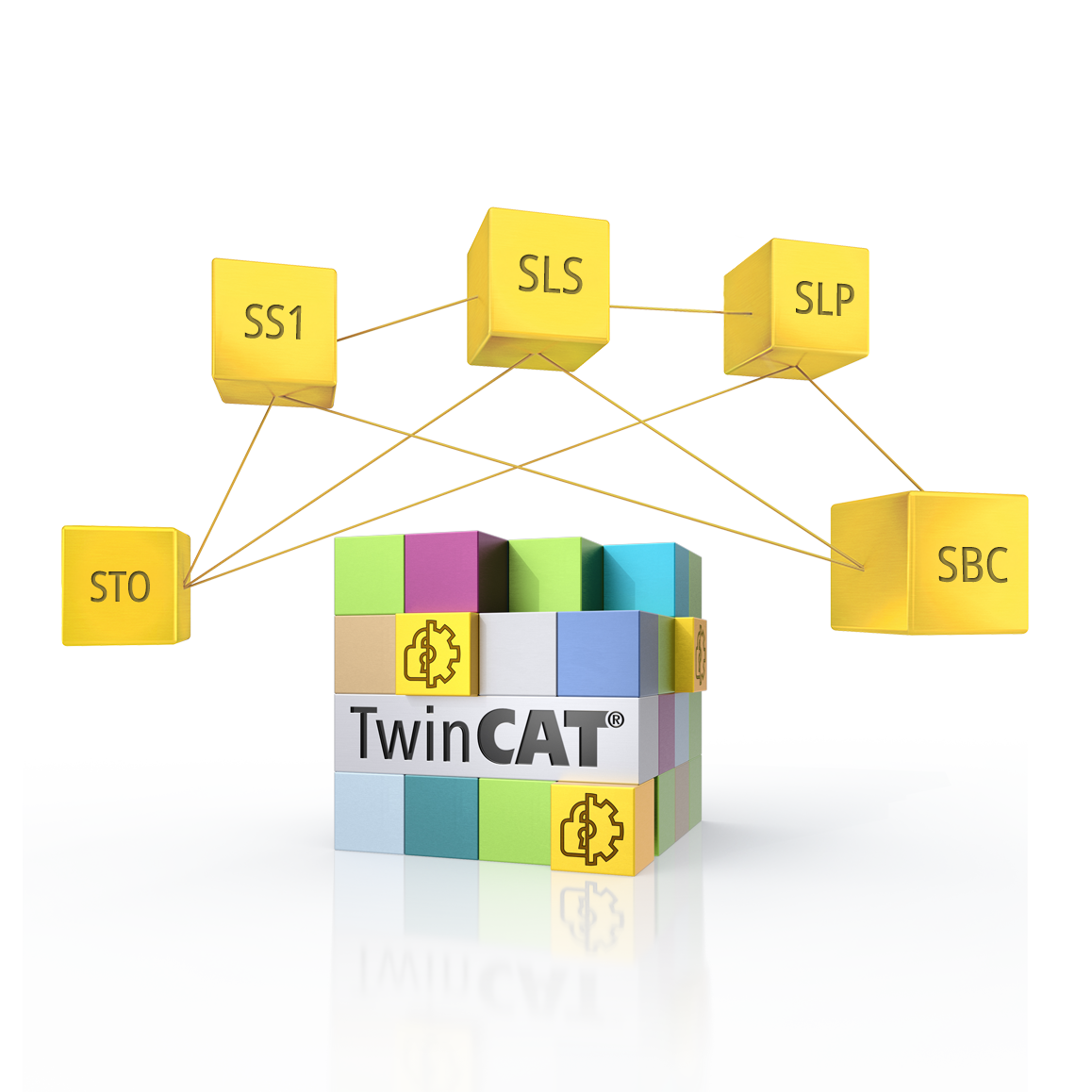

TwinSAFE safe drive technology

With the TwinSAFE safe automation technology, both basic functions and complex safety functions are available for all our drive solutions.

Highly efficient variable frequency drives for the entry-level range

In the 370 W to 3 kW power range, the AF1000 variable frequency drive complements the Beckhoff portfolio with very cost-efficient drive amplifiers. The compact, highly integrated devices are suitable for implementing drive axes with synchronous, asynchronous, and reluctance motors without a feedback system.

Small form factor makes it easier to use small installation spaces

Despite its compact dimensions, the device still manages to incorporate a power supply unit for 24 V DC, intermediate circuit capacitors, and a ballast circuit. The power supply generates the control voltage from the DC link voltage. Both variable frequency drive versions are available as not only single-axis modules, but also highly cost-effective and compact dual-axis modules.

Convenient design, commissioning, and diagnostics with TwinCAT

The ultra-compact variable frequency drive is fully integrated into the TwinCAT system via EtherCAT, providing the usual convenience for commissioning, operation, and diagnostics. The TwinCAT 3 Drive Manager 2 serves as the commissioning tool, and its structured design and wide range of functions make commissioning the axis simple and intuitive.

The design of the drive, particularly the dimensioning of drive axes, in conjunction with optimal selection of the motor, gear unit, drive controllers, and accessories, is the foundation for efficient machine design. The TwinCAT 3 Motion Designer tool can be integrated in the TwinCAT automation platform or used as a stand-alone project engineering tool for drive design.

Drive-integrated safety functions

The AF1000 economy variable frequency drive supports TwinSAFE as an option in order to implement the STO/SS1 drive-integrated safety functions in accordance with IEC 61800-5-2. The associated safety projects can be created quickly and easily with the TwinCAT 3 Safety Editor. The TwinSAFE Loader/User is also available as additional support.