TwinSAFE safe drive technology

Highly scalable, highly modular: Safe drive solutions

Headquarters Canada

Beckhoff Automation Ltd.

Highly scalable, highly modular: Safe drive solutions

Dynamic movements of the electrical drive technology used in a machine can create considerable hazards to people and the environment. From a normative point of view, drive technology components must be considered in a safety-oriented manner by co-ordinating and monitoring certain movements and motion sequences. The integrated safety solution TwinSAFE enables the implementation of safe drive technology in three levels corresponding to the complexity of the machine. The safe drive components are able to switch the motor torque-free or to monitor speed, position and direction of rotation. No further devices such as contactors or circuit breakers are necessary in the supply lines for this. This enables a very lean installation and helps to lower costs and control cabinet space requirements. Even safe position monitoring or position range monitoring is simple to implement with the aid of the safe drive technology. This does not require any additional wiring, because the EtherCAT communication is used in the servo drives, enabling seamless communication between TwinSAFE Logic components and the safe drive technology.

Like the programming or configuration of a safety application, the entire parameterisation of the safe drive technology is performed from the TwinCAT software. All system-specific settings are stored together with the application in the TwinSAFE Logic components. For that reason, the safe drive components can be exchanged at any time without software modification. The respective component receives all the parameters necessary for operation at the next power-on or boot-up.

| Product | AMP8000/AMP8500 | AX1000/AX8000 | AX5805/AX5806 | AF1000/AX5801 | |||||

|---|---|---|---|---|---|---|---|---|---|

| Function | EN 61508:2010 | EN ISO 13849-1:2015 | EN 61508:2010 | EN ISO 13849-1:2015 | EN 61508:2010 | EN ISO 13849-1:2015 | EN 61508:2010 | EN ISO 13849-1:2015 | |

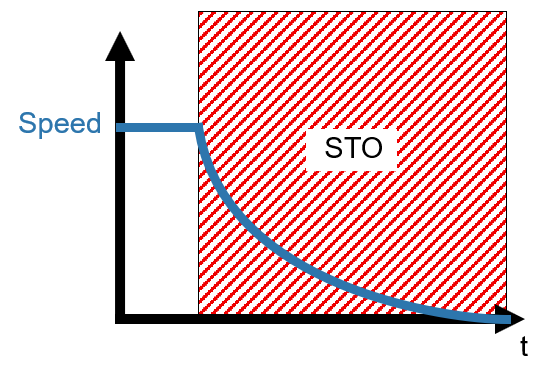

| Stop functions | STO | SIL 3 | Cat. 4, PL e | SIL 3 | Cat. 4, PL e | SIL 3 | Cat. 4, PL e | SIL 3 | Cat. 4, PL e |

| SS1 | SIL 3 | Cat. 4, PL e | SIL 3 | Cat. 4, PL e | SIL 3 | Cat. 4, PL e | SIL 3 | Cat. 4, PL e | |

| SOS | SIL 2 | Cat. 3, PL d | SIL 3 | Cat. 4, PL e | SIL 3 | Cat. 4, PL e | - | - | |

| SS2 | SIL 2 | Cat. 3, PL d | SIL 3 | Cat. 4, PL e | SIL 3 | Cat. 4, PL e | - | - | |

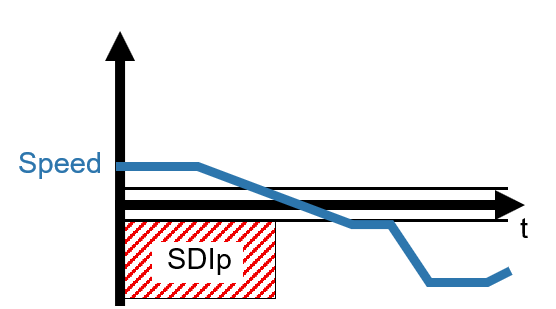

| Rotating direction functions | SDIp | SIL 2 | Cat. 3, PL d | SIL 3 | Cat. 4, PL e | SIL 3 | Cat. 4, PL e | - | - |

| SDIn | SIL 2 | Cat. 3, PL d | SIL 3 | Cat. 4, PL e | SIL 3 | Cat. 4, PL e | - | - | |

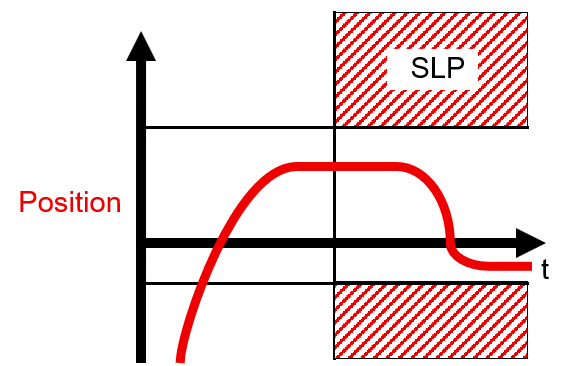

| Position functions | SLP | SIL 2 | Cat. 3, PL d | SIL 3 | Cat. 4, PL e | SIL 3 | Cat. 4, PL e | - | - |

| SLI | SIL 2 | Cat. 3, PL d | SIL 3 | Cat. 4, PL e | SIL 3 | Cat. 4, PL e | - | - | |

| SCA | SIL 2 | Cat. 3, PL d | SIL 3 | Cat. 4, PL e | SIL 3 | Cat. 4, PL e | - | - | |

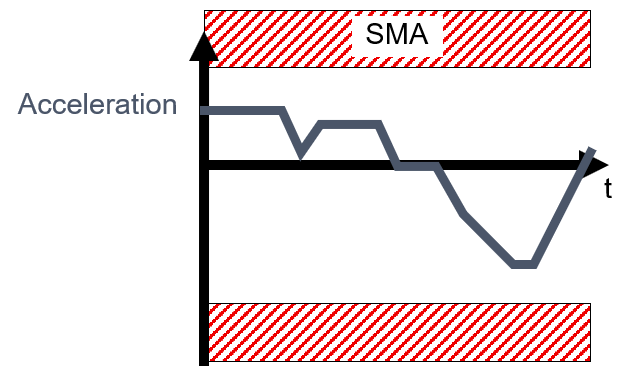

| Acceleration functions | SMA | SIL 2 | Cat. 3, PL d | SIL 3 | Cat. 4, PL e | SIL 3 | Cat. 4, PL e | - | - |

| SAR | SIL 2 | Cat. 3, PL d | SIL 3 | Cat. 4, PL e | SIL 3 | Cat. 4, PL e | - | - | |

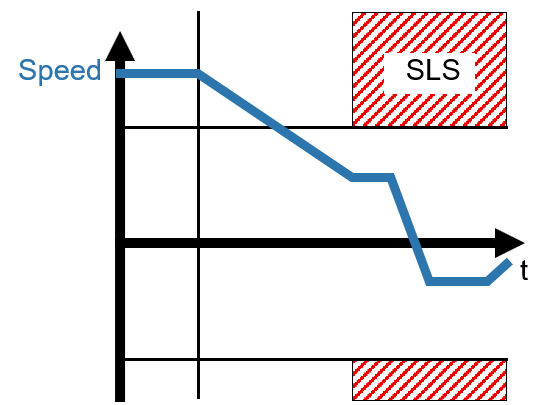

| Speed functions | SLS | SIL 2 | Cat. 3, PL d | SIL 3 | Cat. 4, PL e | SIL 3 | Cat. 4, PL e | - | - |

| SSM | SIL 2 | Cat. 3, PL d | SIL 3 | Cat. 4, PL e | SIL 3 | Cat. 4, PL e | - | - | |

| SMS | SIL 2 | Cat. 3, PL d | SIL 3 | Cat. 4, PL e | SIL 3 | Cat. 4, PL e | - | - | |

| SSR | SIL 2 | Cat. 3, PL d | SIL 3 | Cat. 4, PL e | SIL 3 | Cat. 4, PL e | - | - | |

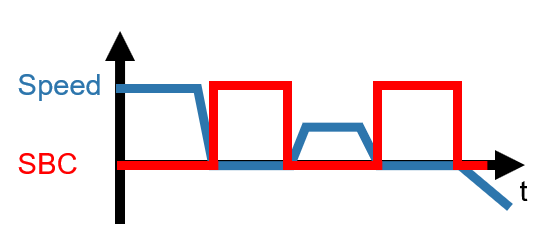

| Brake functions | SBC | SIL 3 | Cat. 4, PL e | SIL 3 | Cat. 4, PL e | - | - | - | - |

| SBT | supports | supports | supports | supports | - | - | - | - | |

| Product | AMI8000 | ELM72xx | EL72xx/EP72xx/EJ72xx | ||||

|---|---|---|---|---|---|---|---|

| Function | EN 61508:2010 | EN ISO 13849-1:2015 | EN 61508:2010 | EN ISO 13849-1:2015 | EN 61508:2010 | EN ISO 13849-1:2015 | |

| Stop functions | STO | SIL 3 | Cat. 4, PL e | SIL 3* | Cat. 4, PL e* | SIL 2 | Cat. 3, PL d |

| SS1 | SIL 3 | Cat. 4, PL e | SIL 3* | Cat. 4, PL e* | - | - | |

| SOS | - | - | SIL 3* | Cat. 4, PL e* | - | - | |

| SS2 | - | - | SIL 3* | Cat. 4, PL e* | - | - | |

| Rotating direction functions | SDIp | - | - | SIL 3* | Cat. 4, PL e* | - | - |

| SDIn | - | - | SIL 3* | Cat. 4, PL e* | - | - | |

| Position functions | SLP | - | - | SIL 3* | Cat. 4, PL e* | - | - |

| SLI | - | - | SIL 3* | Cat. 4, PL e* | - | - | |

| SCA | - | - | SIL 3* | Cat. 4, PL e* | - | - | |

| Acceleration functions | SMA | - | - | SIL 3* | Cat. 4, PL e* | - | - |

| SAR | - | - | SIL 3* | Cat. 4, PL e* | - | - | |

| Speed functions | SLS | - | - | SIL 3* | Cat. 4, PL e* | - | - |

| SSM | - | - | SIL 3* | Cat. 4, PL e* | - | - | |

| SMS | - | - | SIL 3* | Cat. 4, PL e* | - | - | |

| SSR | - | - | SIL 3* | Cat. 4, PL e* | - | - | |

| Brake functions | SBC | - | - | - | - | - | - |

| SBT | - | - | - | - | - | - | |

The variable frequency drives in the AF1000 series are particularly suitable for performing basic drive tasks cost-effectively.

The AX1000 economy servo drive for implementing demanding and cost-sensitive drive tasks.

The AX8000 is the space-saving solution for applications with more than two axes. Extensive TwinSAFE functions allow a safe machine design.

The AX5000 is offered in a wide performance range and offers a flexible motor and feedback interface as well as optional TwinSAFE functions.

The AMP8000 motors with integrated servo drive for the realization of modular control cabinet free machine concepts.

AMP8500 for the realization of modular control cabinet free machine concepts with high requirements on synchronism and control quality.

Synchronous servomotor with integrated servo drive for the realization of machine concepts without a control cabinet in the low voltage range.

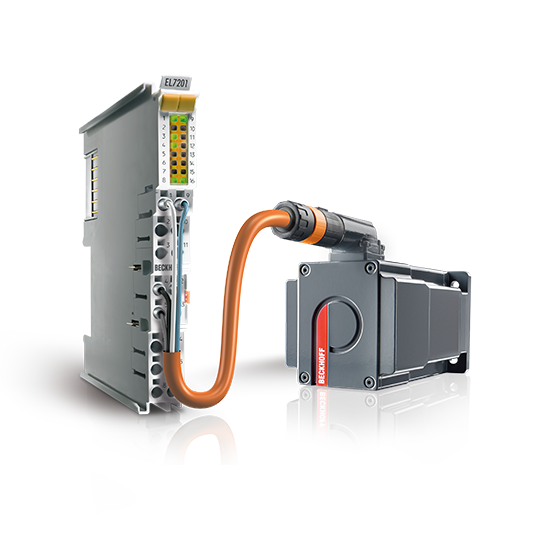

The I/O components in different protection classes enable the operation of stepper, DC and servomotors in a compact design.