The operation and maintenance of modern wind turbines incurs considerable costs. To maintain competitiveness, failure risks must be minimized, maintenance costs lowered and the availability and energy efficiency of the system increased. This is where condition monitoring enters the game: monitoring of gear units and generators is generally recommended, not just for offshore wind turbines or systems in remote regions.

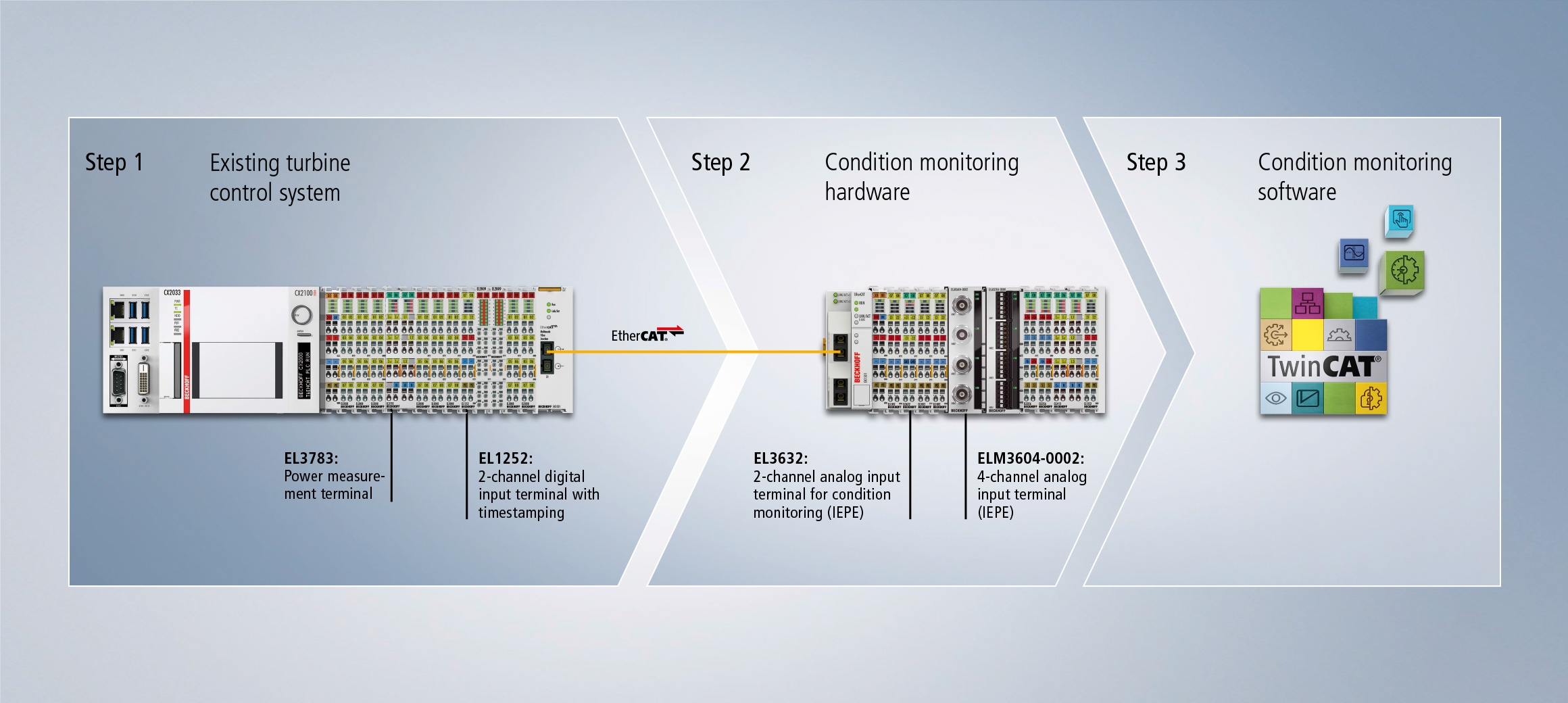

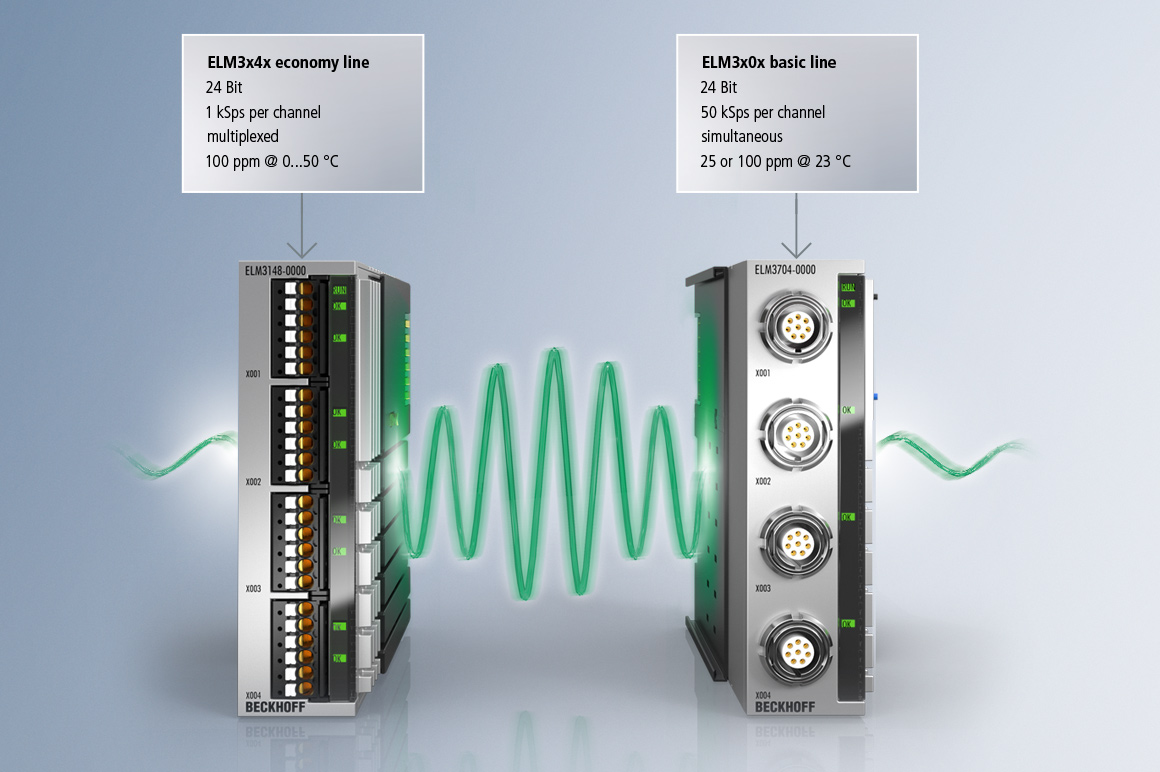

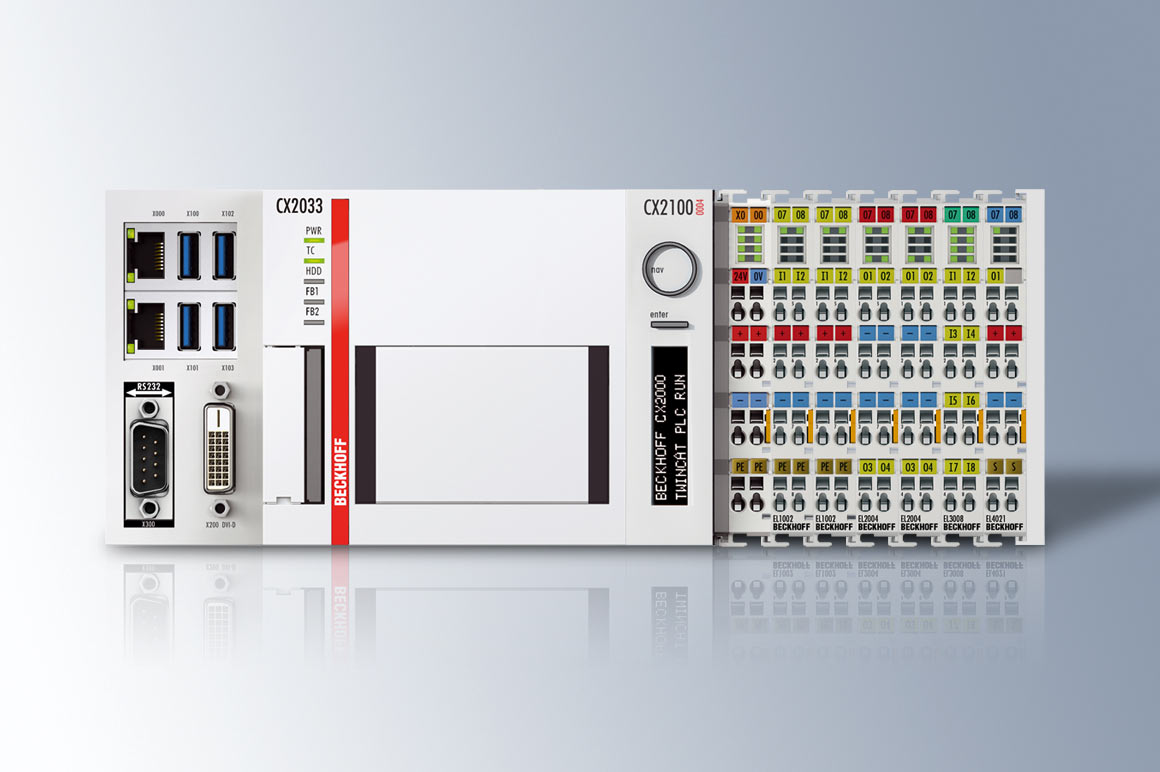

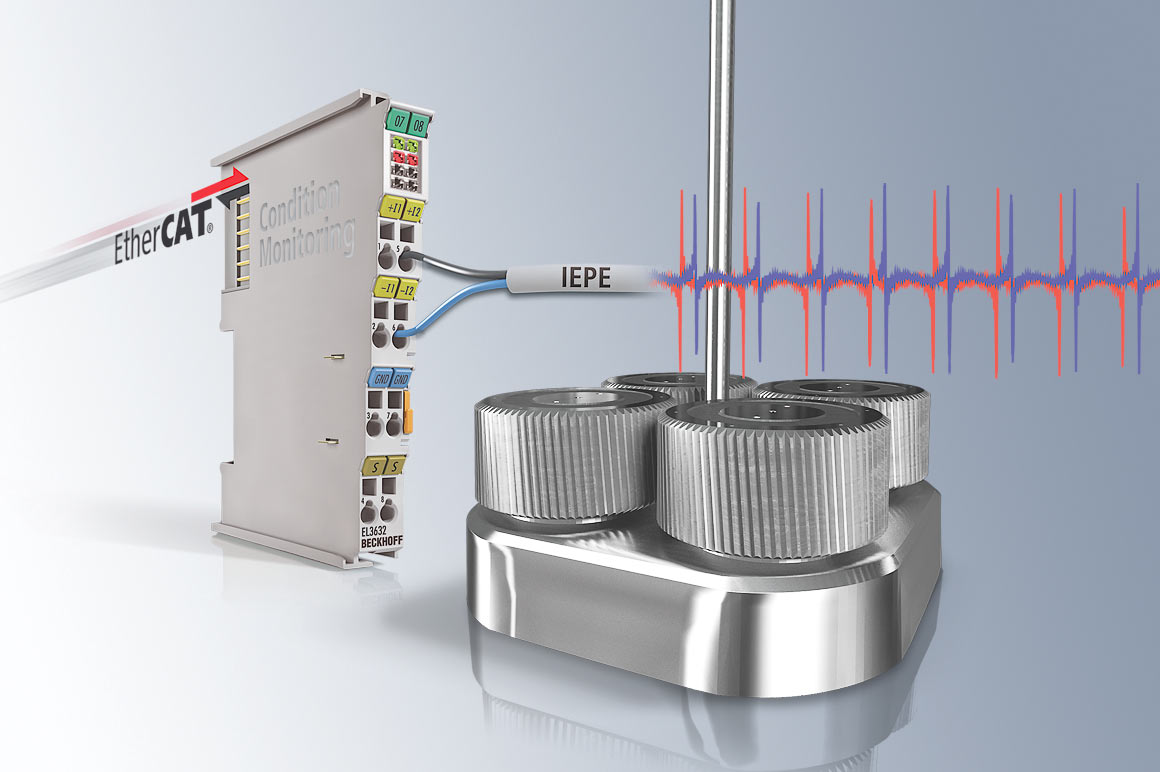

Beckhoff combines the powerful processors of modern PC technology together with EtherCAT as fast communication system, integrating condition monitoring functionality seamlessly into the controller. The vibrations of bearings or electrical machines are picked up by standard measurement terminals from Beckhoff and transmitted to the controller via EtherCAT. Configuration, programming and diagnostics are carried out within one system using TwinCAT. With improved error detection and holistic system analysis capabilities, the control system-integrated condition monitoring from Beckhoff is superior to conventional hardware-based condition monitoring solutions. Through integration of further signals from operational management, including temperature, pressure and current, among others, false alarms can be prevented and error detection is improved. Integration of condition monitoring into the central PC-based controller is advantageous, in particular where large amounts of data from different devices need to be analyzed or if damage frequencies need to be evaluated in relation to the rotary speed. The controller acquires and processes the signals in the microsecond range.

However, cost reductions with regard to system, installation and maintenance also highlight the merits of system-integrated condition monitoring. Existing systems can be retrofitted simply and inexpensively.

System-integrated condition monitoring offers:

- time-synchronous data logging in << 1 μs

- reliable data analysis

- enhanced diagnostics

- increased system availability

- longer service life of wind turbines

- reduced maintenance costs

- reduced system costs

- enhanced competitiveness