Labeling and grouping unit in a packaging line for toothbrushes

Koch Pac-Systeme, Germany

Sídlo Česká republika

Beckhoff Automation s.r.o.

+420 511 189 250

info.cz@beckhoff.com

www.beckhoff.com/cs-cz/

Koch Pac-Systeme, Germany

The change of the requirements in the print industry towards an end-to-end digital workflow is aimed at the complete networking of all sub-processes, from the order preparation and pre-print stage to the actual printing process through to print processing and dispatch handling. On the part of the control system, this requires a high degree of communication, interface variety and the handling of large quantities of data. These requirements are optimally fulfilled by the PC- and EtherCAT-based control technology. By utilizing Beckhoff Industrial PCs with PC-based control, the PLC, motion control, safety technology, robotics, measurement technology and HMI can all run on the central TwinCAT automation platform. This ensures efficient interaction of all system components and enables maximum productivity. The open hardware and software interfaces provide high degrees of freedom in machine design and enable a large number of different peripheral devices to be integrated. Support for all common fieldbus systems and software protocols guarantees integrated communication from the field level to the cloud. Thanks to the modularity and scalability of the individual components, customized, cost-effective printing applications can be created – regardless of whether it is the end-to-end automation of a new production line or the control retrofit of an existing machine.

Digital printing is a relatively new printing process but is becoming increasingly popular because of its flexibility. In contrast to conventional processes, digital non-impact printing (NIP) does not require a static printing plate and is therefore particularly suitable for cost-effective production, with plenty of room for customization of print products. The application spectrum ranges from commercial sheet-fed or web printing to label and packaging printing. A wide variety of materials and surface forms can be printed. The technical challenges facing digital printing can only be mastered with open, digitally networked control technology. Thanks to its scalability, modularity and high degree of integration, PC-based control from Beckhoff is suitable as a universal control system for the entire process chain, from digital image creation to the finished print product. By supporting standardized interfaces, such as OPC UA, the machine control can be easily integrated with any production environment, thus keeping the integration effort to a minimum.

The advantages of the Beckhoff solution at a glance:

The trend in packaging printing is towards ever-increasing quality while taking sustainability and costs into account. The finer details of the requirements for packaging printing differ depending on the industry or end product such as consumer goods, food or pharmaceuticals, for example. While continuous traceability plays a key role for pharmaceutical products, other applications are more focused on cost-effective production of rapidly changing production cycles and small batch sizes. Since the external appearance of goods has a major influence on the purchasing behavior of consumers, manufacturers try to reach their customers by individualizing product series or personalizing individual products through appropriate packaging printing. In addition, there is the rapid development of new products and formats that require faster and more efficient production while maintaining the highest quality. In order to be able to produce small quantities – down to lot size of one – economically, the printing machine must be very flexible.

The advantages of the Beckhoff solution at a glance:

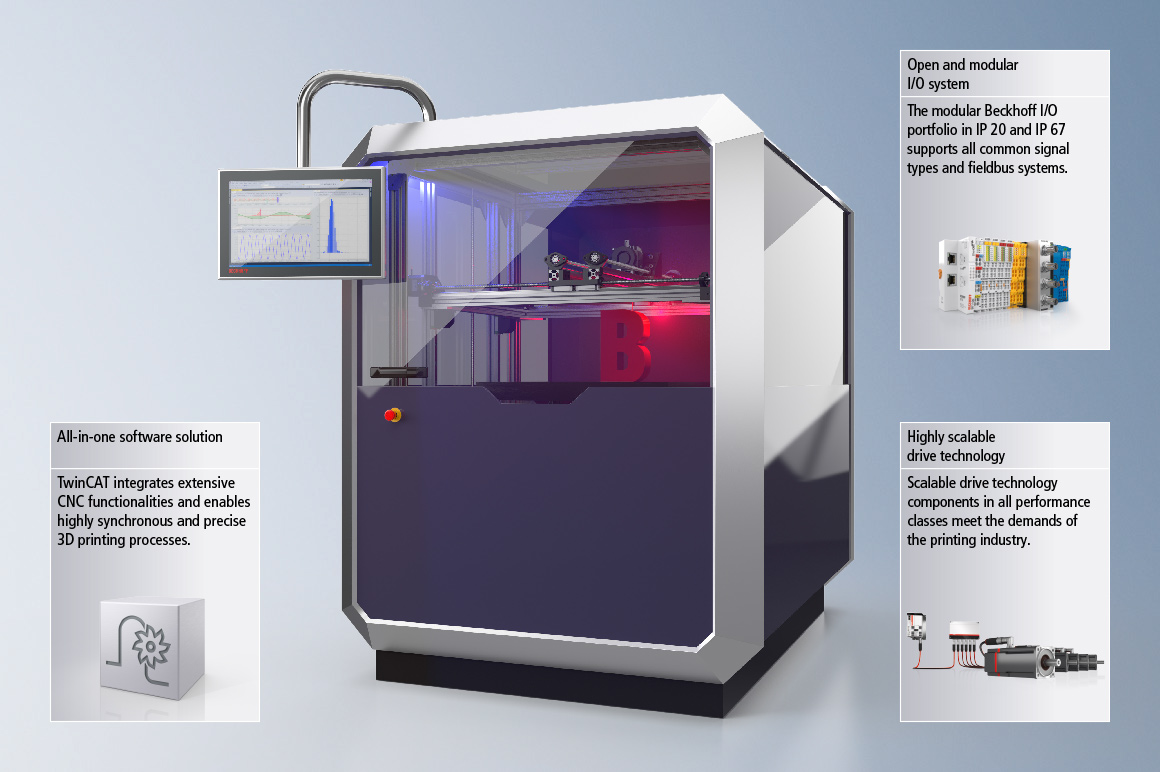

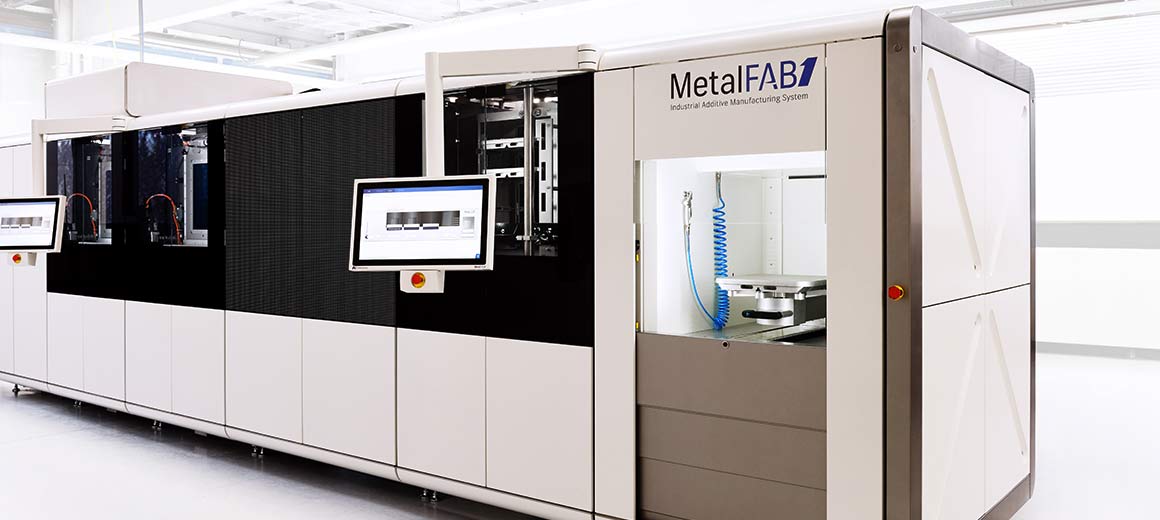

Additive manufacturing processes are suitable in particular for flexible production processes with small numbers of items. With an extensive portfolio of software and hardware components, Beckhoff supports machine manufacturers in the implementation of innovative machine concepts that optimally meet the high market requirements in terms of product quality, speed and flexibility. The basis for the realization of high-precision and efficient 3D printing applications is Beckhoff's many years of experience in the CNC sector, which has been incorporated into the development of a complete CNC solution. It offers users an automation toolkit consisting of scalable and modular components. The all-in-one TwinCAT CNC maps all CNC functions on a software platform. TwinCAT CNC and NC I cover the complete range of conventional CNC path control, including high-end systems for complex motion and kinematics requirements. A maximum of 128 interpolating axes can be controlled with up to 20 channels with extensive coordinate and kinematic transformations. State-of-the-art control algorithms enable precise and highly synchronous processing. TwinCAT TcCOM provides an open interface through which customers can safely integrate their own process knowledge in the form of special, customized functionalities into the standard controller.

In combination with the motion control solutions of the TwinCAT automation software, Beckhoff Drive Technology offers a high-performance solution for all areas of application, including ultra-compact servo terminals and motors with integrated servo drive from the Beckhoff AMP8000 series to the AX5000 and AX8000 EtherCAT servo drives for the medium and upper performance class, with corresponding servomotors.

Thanks to high-performance EtherCAT I/O terminals, users have access to more than 100 signal types in variable channel density, from high-precision measurement technology to safety technology and compact drive technology. In addition, all common fieldbus systems are supported, so that users benefit from optimum flexibility and openness with regard to I/O structures. The integration of local or cloud-based applications for data analysis and automatic generation of dashboards via the TwinCAT Analytics software tool enables monitoring of machine states. For example, the print head can be monitored at any time and from any location, reducing machine downtime and enabling predictive maintenance.

The advantages of the Beckhoff solution at a glance: