Products

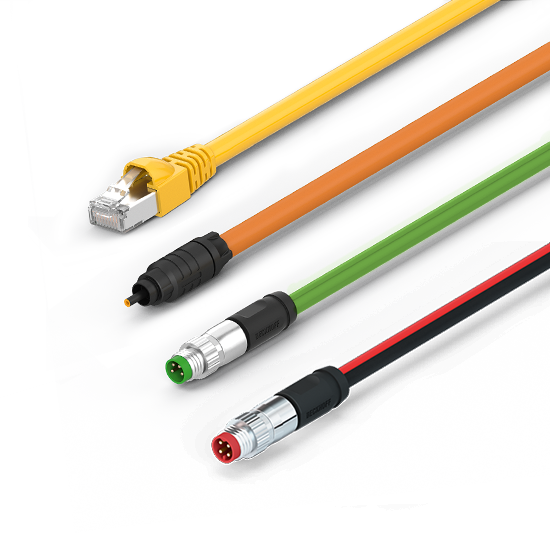

EtherCAT and fieldbus cables

The EtherCAT and fieldbus cables ensure reliable data transmission and are optimized for industrial applications and harsh environmental conditions.

Power cables

Power cables are available in diverse codings and sizes to support reliable voltage supply for your application.

Sensor cables

The comprehensive product range of sensor cables can be configurated individually or as a cable set for quick installation on the machine.

Hybrid cables

The combination of power supply, signal and data communication in one connector. Hybrid cables are available in application-specific sizes and performance classes.

Motor cables

OCT/motor cables for permanent installation or highly flexible for use on drag-chains and robots.

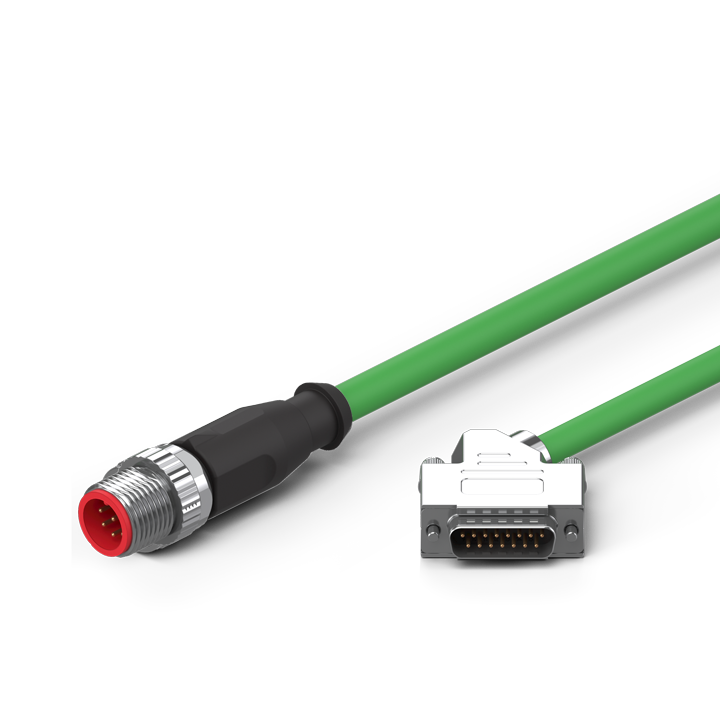

Feedback cables

Feedback cables for permanent installation or highly flexible for use on drag-chains and robots.

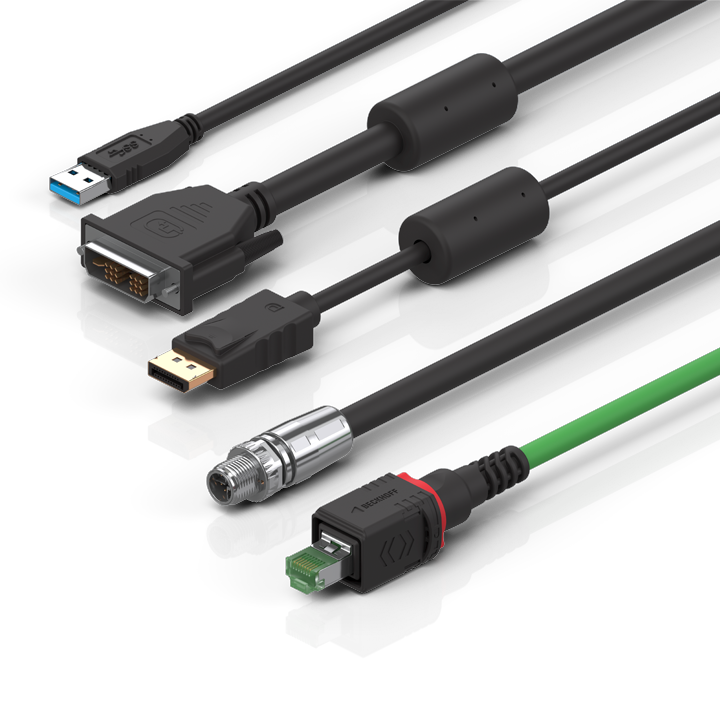

IPC cables

Extensive range of accessory components for Industrial PCs, Control Panels and Panel PCs.

MX-System cables

Accessories that are perfectly adapted to the MX-System for efficient, safe installation.

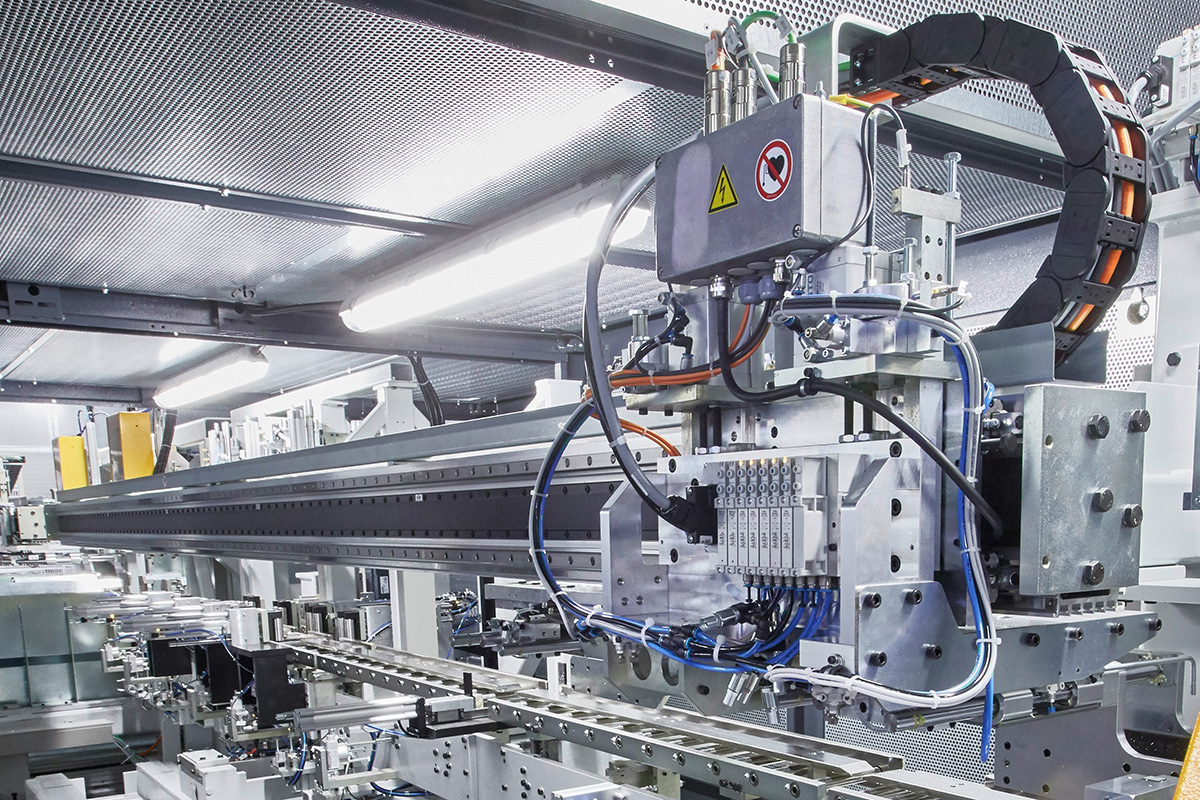

Fully tested plug-and-play solutions from the automation specialists

Beckhoff offers an extensive range of preassembled cables for safe, faster, and error-free installation. The selection of pre-assembled cables includes numerous lengths and variants with no minimum order quantity; standard lengths and custom lengths are available ex stock.

Our pre-assembled cables include connectors that are designed according to the latest standards, such as IEC 61076-2-111 for M12 power connectors or IEC 61076-2-114, which specifies the P-coding for EtherCAT P connectors.

The assemblies are fully tested electrically, mechanically, and optically and have at least one pre-installed connector.

The reliability of these products is guaranteed through an individual batch number. In this way, it is possible to trace which material was used for assembly and which staff member carried out the respective work step and at what time. In addition to the simple configuration check and visual inspection of the product, advanced tests are carried out, such as high-voltage tests to locate damage to the core insulation or a resistance test to check the correct cable length.

Advantages

- IP20, IP54, IP65, IP66, IP67 and IP69K protection rating, suitable for the industrial environment

- UL/CSA-approved, pre-assembled cables

- perfect 360° shield connection for optimum electromagnetic compatibility (EMC)

- sturdy for higher shock and vibration requirements

- fast cabling through screw and bayonet connection

- the matching size and coding for every application: RJ45, M8, M12, M23, M40, B12, B17, B23 and B40

Customer-specific cables

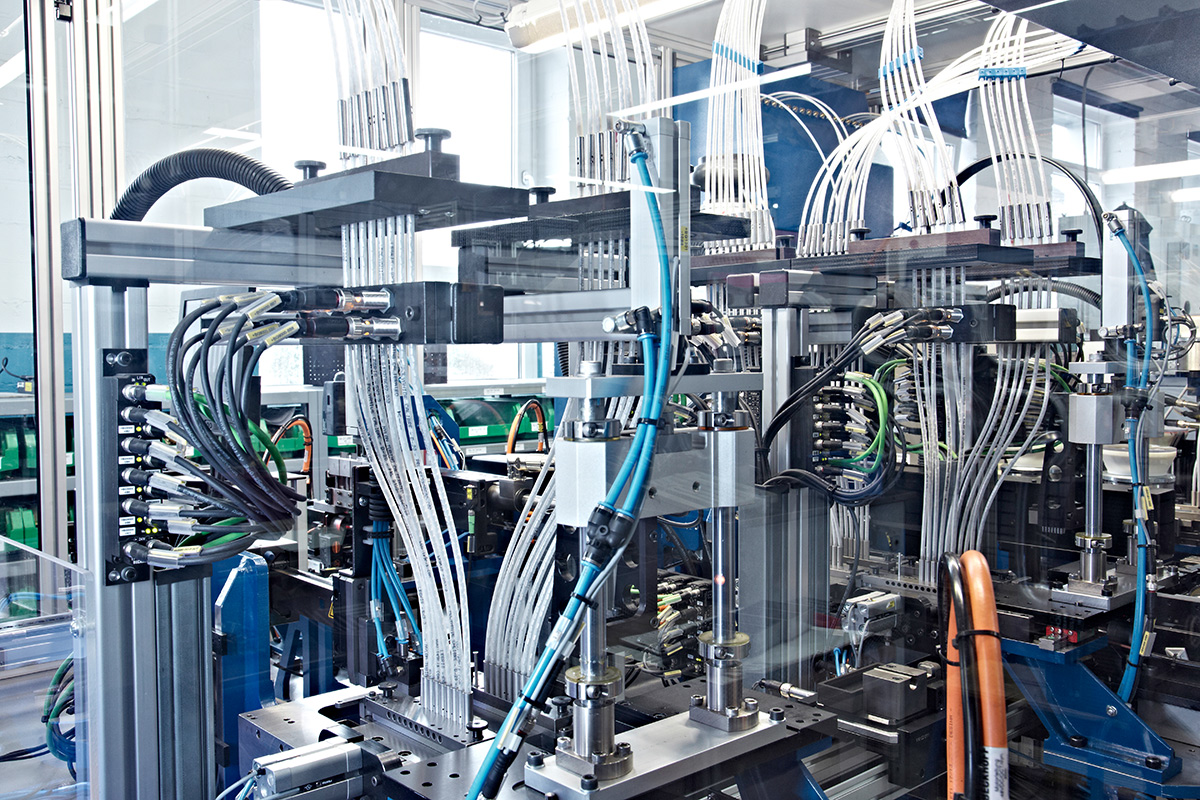

In addition to individual pre-assembled standard cables for connection between Beckhoff devices, Beckhoff also supplies individual, customer-specific cables and complete cable sets for the entire machine cabling. This covers the whole process, from consultation to preparation of the documentation and production of the tested assemblies.

Connection technology for…

- dust and waterproof connectors according to IP65/IP67 standard

- resistant to the harshest environmental conditions, such as oils and lubricants

- 100% pre-tested plug-and-play solutions from size M8 to B40

- IP69K-tested components for use in the food & beverage sector

- Field-tested cable qualities, such as PVC or PP, withstand aggressive cleaning agents.

- Supply, sensor, and communication cables with stainless steel connectors offer secure handling during installation.

- Bulkhead and cable bushings from size M8 to B23 allow rapid servicing of individual machine segments.

- smallest bending radii in drag chains up to 7 x cable outer diameter

- drag chain cables for travels > 25 m and up to 20 million alternating bending cycles

- Torsion-capable cables with a maximum torsion angle of ±720° are used in robots or handling systems.

- pre-assembled cable harnesses for quick and error-free installation at the machine

- years of experience with the installation of pre-equipped customer-specific hose packages