Products

Cameras

Robust cameras with highly flexible mounting options and a bandwidth of up to 2.5 Gbit/s offer a range of services tailored to industrial PCs.

Optics

Robust, industrial-grade and investment-safe lenses guarantee easy handling and high availability.

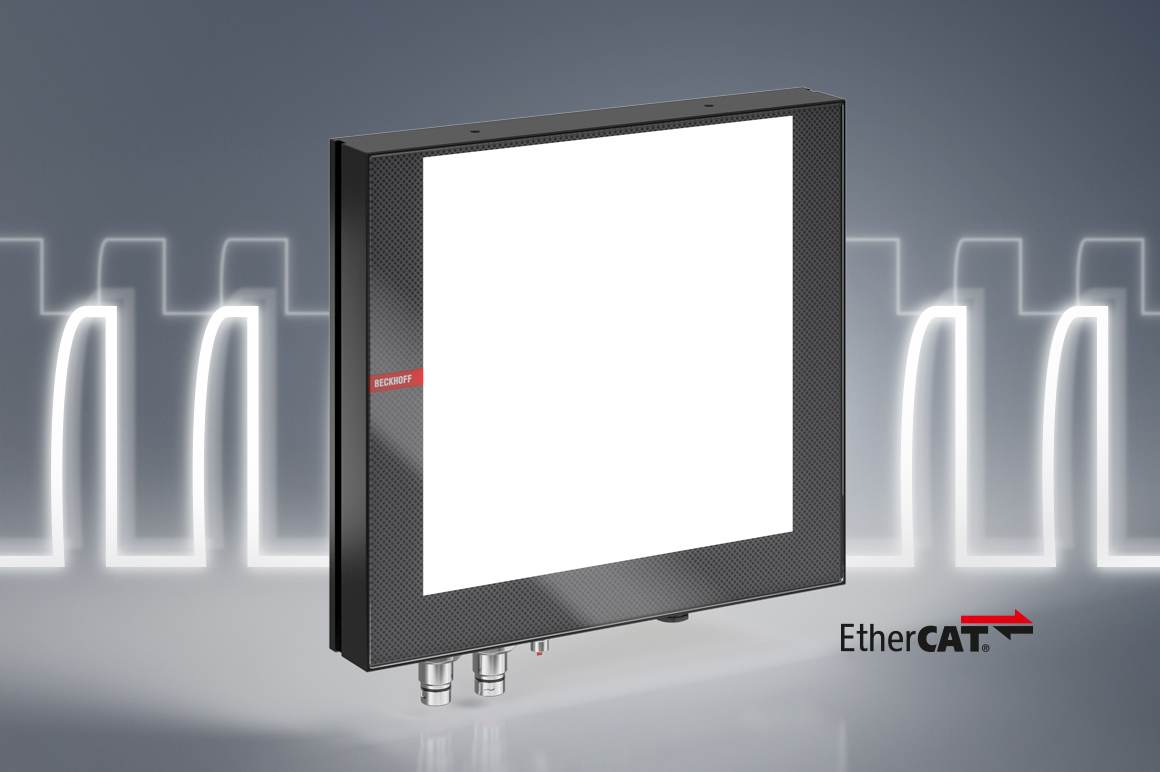

Illumination

Spectrally adjustable, temperature-stable, and reliable illumination supports EtherCAT-based applications.

Units

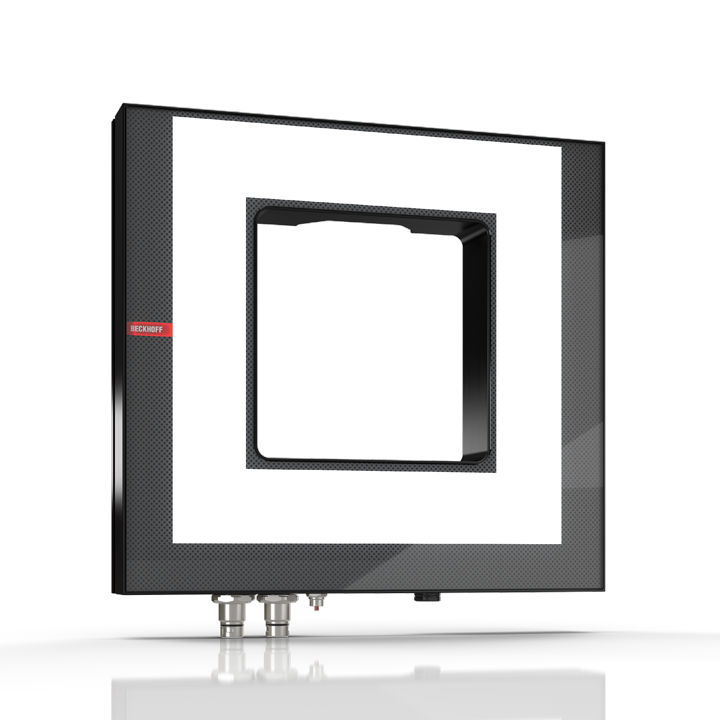

Start industrial image processing immediately with the Vision Unit Illuminated (VUI)

Vision-specific accessories

Complete, tried and tested range of accessories that optimally integrates the vision hardware.

Complete vision portfolio

As a specialist for PC-based control technology, Beckhoff consistently aims to integrate all machine functionalities into one control platform. With TwinCAT Vision, this has included image processing within software since 2017. The machine vision product spectrum is now complete thanks to the introduction of the comprehensive hardware range from Beckhoff. Machine builders and end users thus have a complete industrial image processing system at their disposal that covers all the necessary components from software to illumination which, integrated into the system, provides users with significant competitive advantages.

Seamless system integration with

- cameras

- optics

- illumination

- complete units

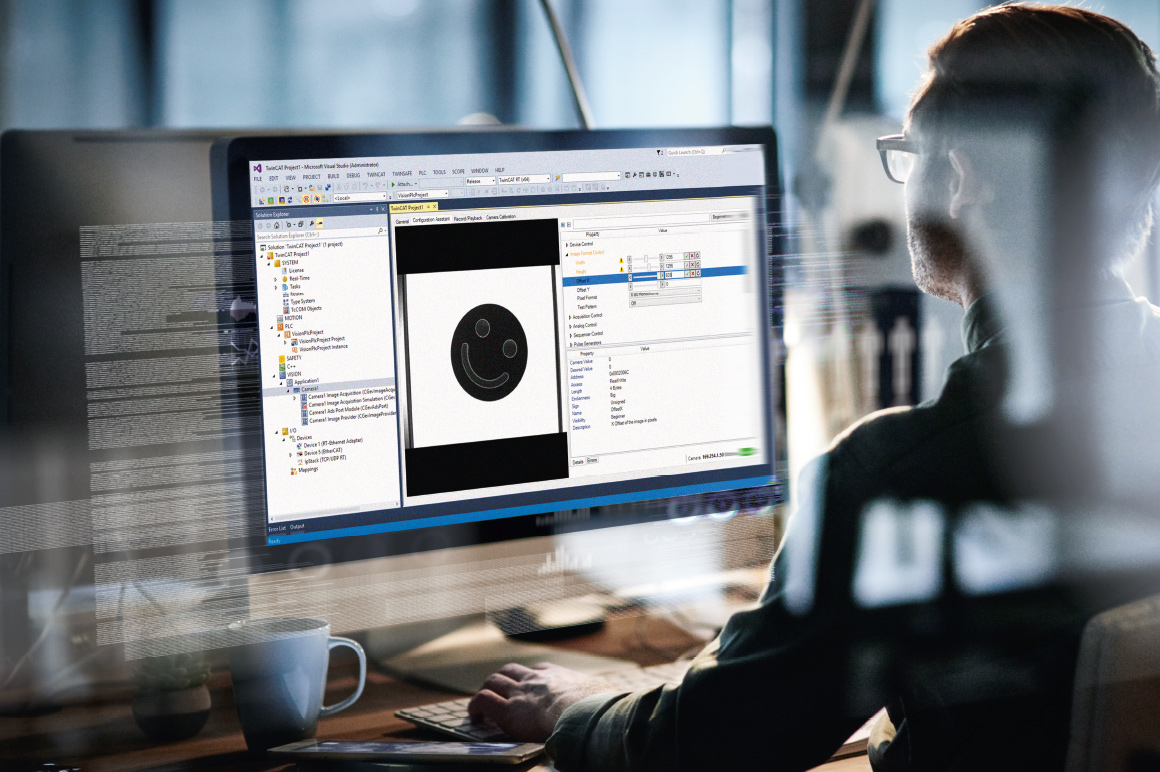

- software

- training and support

With Beckhoff Vision, real-time image processing can be easily integrated into both new and existing control environments, as well as optimally synchronized with all machine and plant processes. Here, the previously strict separation between vision and automation technology is further eliminated through system integration in all environments. At the same time, Beckhoff Vision components win users over with their robust, attractive design as well as high scalability and long-term availability.

A balanced hardware portfolio for vision applications

Advantages at a glance

Complete vision system comprising hardware and software for industrial use

- synchronizable with all control processes

- consistent interaction with all other components

- implemented in the standard automation application

- illumination optionally integrated (unit) or available separately

Direct integration simplifies vision project planning and lowers costs:

- reduced engineering and hardware costs

- easy system integration and commissioning

- straightforward support

Seamless embedding in PC-based control systems

- support for the established international standard GigE Vision

- industry-independent range of applications without limitations on integration

- full scalability of the image processing system due to scalability of camera, resolution, illumination, and computing power

- simple integration into existing production environment thanks to open system architecture

- maximum freedom in vision configuration

- simplified adaptation of the vision solution and architecture to changing requirements

- individual components are easy to replace

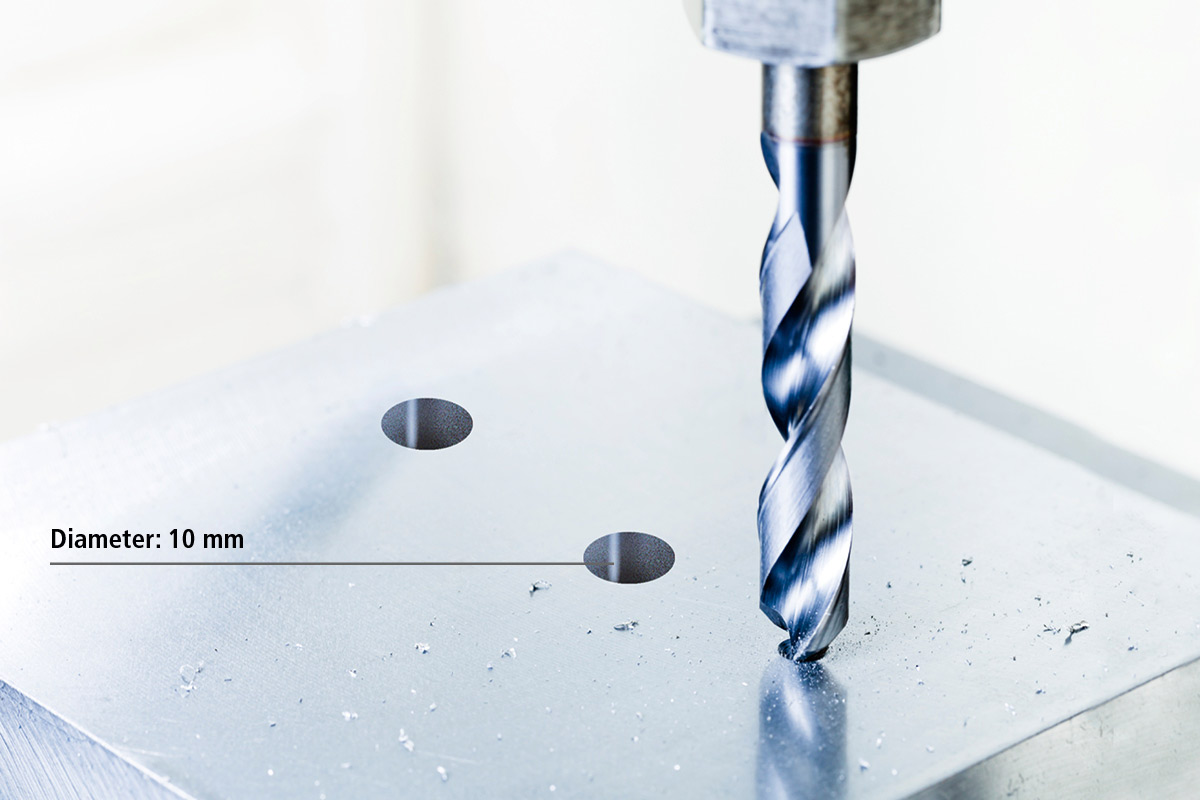

Full integration in EtherCAT supports real-time applications

- simplified and synchronized trigger generation for image capture and exposure directly from the system

- direct synchronization and linking with all control processes and cloud-based services

- increased process efficiency through shorter response times, higher cycle rates, and accelerated machining processes

- reduced hardware, wiring, waiting time, installation space, and footprint

- simplified diagnostics

Fusion of different sensor results

- increases reliability

- ensures reliable results in the evaluation

- offers future security

- opens up advanced application options

- creates competitive advantages

Technically outstanding design for industrial applications

- IP65/IP67 housing made of anodized aluminum and glass

- smooth glass surfaces for optimized resistance to cleaning agents and other chemicals

- various options for fastenings and possible uses

- optional splinter protection

Beckhoff’s own vision development and production ensures the best possible vision solution in terms of technology and quality:

- featuring a consistently high level of quality and functionality as well as robust product design of the components

- draws on long-term partnerships with leading technology and component suppliers

Full scalability of the vision system

All components are optimally matched to each other and can be combined according to the modular principle to suit the vision application. The flexibility and scalability make it easy for users to start their own vision applications, implement them efficiently, and expand them further. For simple integration, including into existing control systems, the unit is available as a complete solution consisting of a camera, illumination, and focusable lens.

- camera

- lens resolution

- illumination

- computing power

- complete solution consisting of a camera, illumination, and focusable lens

High-precision control and efficient electronics minimize energy requirements

- EtherCAT P with distributed clocks functionality and responsive power electronics enable high-precision synchronization with all machine processes without unnecessary illumination times.

- Blue LED chips form the basis for high light output and temperature stability, as well as increased efficiency at high ambient temperatures.

- The EtherCAT-controlled flash mode reduces the power supply and the required cooling effort while also decreasing the energy consumption of the lighting.