Interview with Dr. Fabian Assion

The energy transition requires grids with comprehensive measurement technology

Interview with Dr. Fabian Assion

The energy transition requires grids with comprehensive measurement technology

Headquarters United States

Beckhoff Automation LLC

+1 952 890-0000

beckhoff.usa@beckhoff.com

www.beckhoff.com/en-us/

Interview with Dr. Fabian Assion

Interview with Dr. Fabian Assion

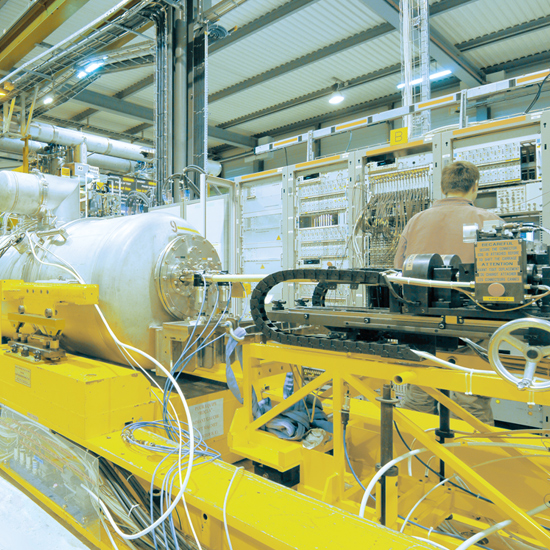

Efficiency, flexibility, and transparency are crucial for sustainable competitiveness. For production machines, the focus is on efficiency and reliability, while test bench technology requires flexibility in terms of interfaces, sensor technology, and actuators. Advanced test benches require dynamic control systems and precise, calibrated measurement data. Operators want to make their systems future-proof, for example through new safety technology, condition monitoring, or energy measurement to optimize consumption.

With our system-integrated measurement and testing technology, we provide you with a modular range of measuring hardware and software products for designing advanced, high-performance DAQ systems.

Do you have any questions?

System-integrated measurement technology increases the competitiveness of machines.

Dynamic measurement technology optimizes test benches in research and laboratories.

IIoT-enabled solutions offer transparency for machines and energy distribution.

Artificial intelligence (AI) is an effective technology for automating processes. Machine learning (ML) as an AI method is ideal for detecting patterns or anomalies in large amounts of data. However, there are often not enough AI experts to be able to implement artificial intelligence on a broad scale.

With the system-integrated TwinCAT Machine Learning AI range, programmers can develop high-quality AI models based on their processes without any AI expertise and have them executed in the machine controller in real time.

TwinCAT Analytics is a product family for the comprehensive analysis of machine data, from a single local machine to many machine parks distributed across locations. Several tools map the complete workflow, from raw data acquisition and evaluation with various algorithms to the archiving and display of live and historical machine data, e.g., in TwinCAT Analytics One-Click Dashboards.

Since on-premises applications are increasingly being moved to cloud systems, there is also a need for machines and systems to feed their production and status information into these systems. TwinCAT IoT provides the necessary connectivity via OPC UA, MQTT, or REST.

MATLAB® and Simulink® are established programming environments in science and industry. With TwinCAT Target for MATLAB® and Simulink® as well as TwinCAT Interface for MATLAB® and Simulink®, Beckhoff supports deep integration of both tools in TwinCAT.

Starting from engineering in Simulink®, instantiable TwinCAT Object Models (TcCOM) can be generated, which are triggered directly via a real-time task or called via other TcCOMs. This allows, for example, observers or virtual sensors to be created that can be executed in real time or the behavior of non-existent components (hardware-in-the-loop) to be simulated in real time. With TwinCAT Target for MATLAB®, the functions developed in the MATLAB® scripting language can be translated into C/C++ code using MATLAB® Coder™ and used in TwinCAT.

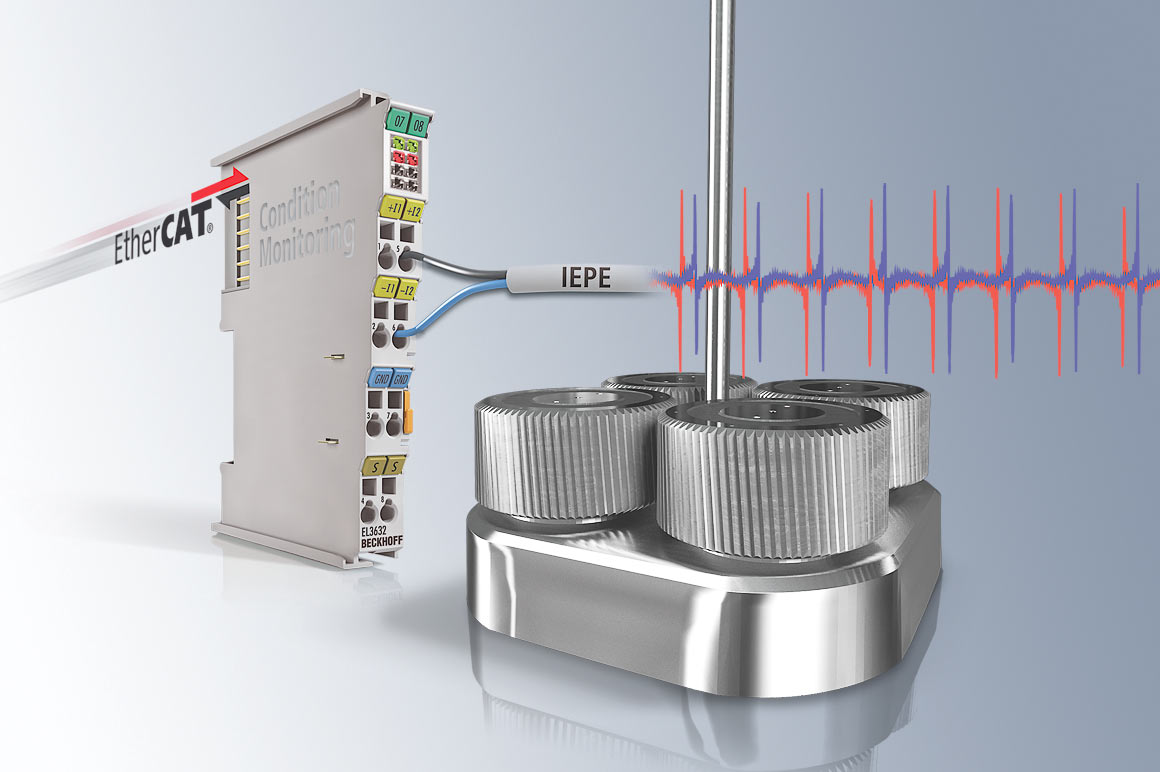

The advantages of proactive maintenance are undisputed: the reliability of the systems increases, maintenance costs fall, and production output remains at a consistently high level.

Beckhoff’s flexible measurement technology program and the TwinCAT condition monitoring library provide all the necessary tools for implementing highly effective machine condition monitoring based on proven PC-based control technology and high-performance communication via EtherCAT. Our condition monitoring products have also been used to monitor wind turbines for many years.