Happy holidays

We wish you happy holidays and a joyful new year!

Installation of wind turbines in any weather

Fast control technology reliably compensates for rotor blade movements caused by wind load

Our innovations at a glance

Discover our latest product developments, extensions, and innovations

Next generation PLC technology

TwinCAT PLC++: Engineering and runtime with a significant leap in performance

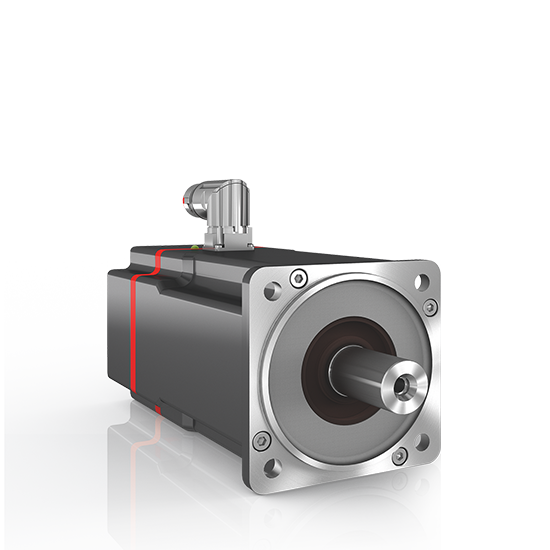

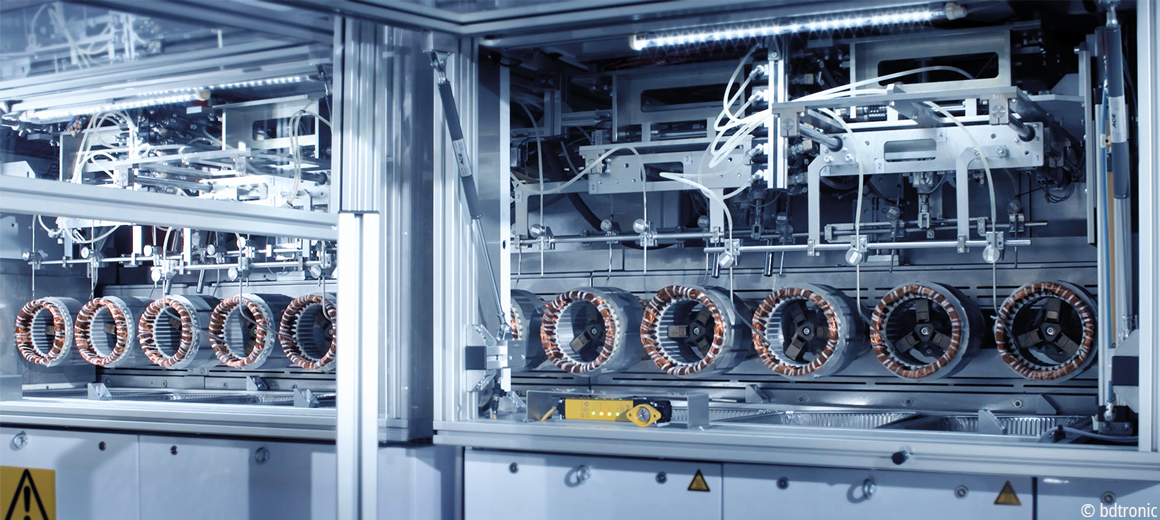

The perfect process solution for e-mobility

PC-based control for trickle impregnation systems for electric motor production