Successful financial year 2023

Beckhoff increases its global sales by 16% to €1,75 billion

TwinCAT and PC-based control for waterjet cutting systems

A precise and fast way to the perfect contour

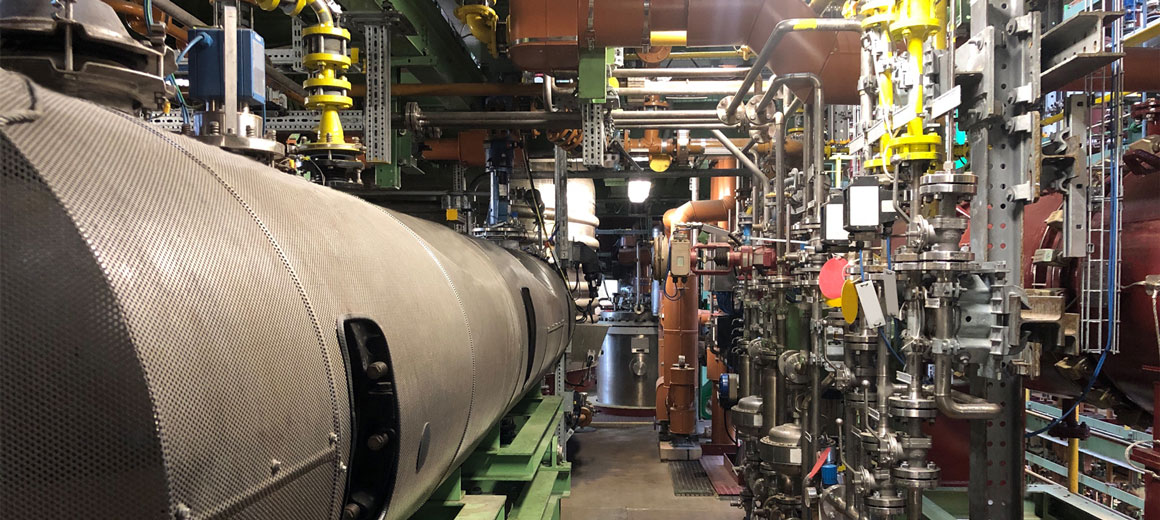

Bayer AG implements NOA with PC-based control

Achieving increased efficiency while switching to state-based maintenance without changing the established control technology